Fabric take-up deviation preventing device

A fabric roll and anti-deviation technology is applied in the field of narrow webbing, which can solve the problems of affecting the appearance, uneven left and right tension of the fabric, affecting the beauty of the fabric, etc., and achieves the effects of simple processing, low cost and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

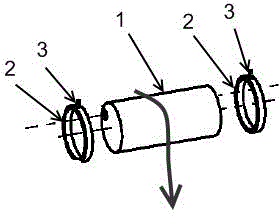

[0022] refer to image 3 As shown, a fabric winding anti-deviation device includes a roller 1 for fabric winding, and a retaining ring 2 is sleeved on the roller 1 .

[0023] At least two retaining rings 2 are sleeved on the roller shaft 1, and two retaining rings 2 are provided in this embodiment.

[0024] like Figure 4 and Figure 5 As shown, the ring wall of the retaining ring 2 is provided with a radial threaded hole 21 .

[0025] The threaded hole 21 on the wall of the retaining ring 2 is a through hole.

[0026] The retaining ring 2 is fastened on the roller shaft 1 through the threaded hole 21 and the corresponding screw 3. In this embodiment, the inner diameter of the retaining ring 2 is Φ40H11, and the diameter of the threaded hole 21 is M3, which matches the inner diameter of the retaining ring 2 The outer diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com