Cloth rolling mill with water liquid collecting device

A collection device and water liquid technology, which is applied in the equipment configuration of textile materials and the removal of liquid/gas/steam with squeeze rollers, etc., can solve the problems of water liquid not being collected and rolling water liquid polluting the environment, etc., to achieve Prevent water splashing, ensure collection, and protect environmental sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

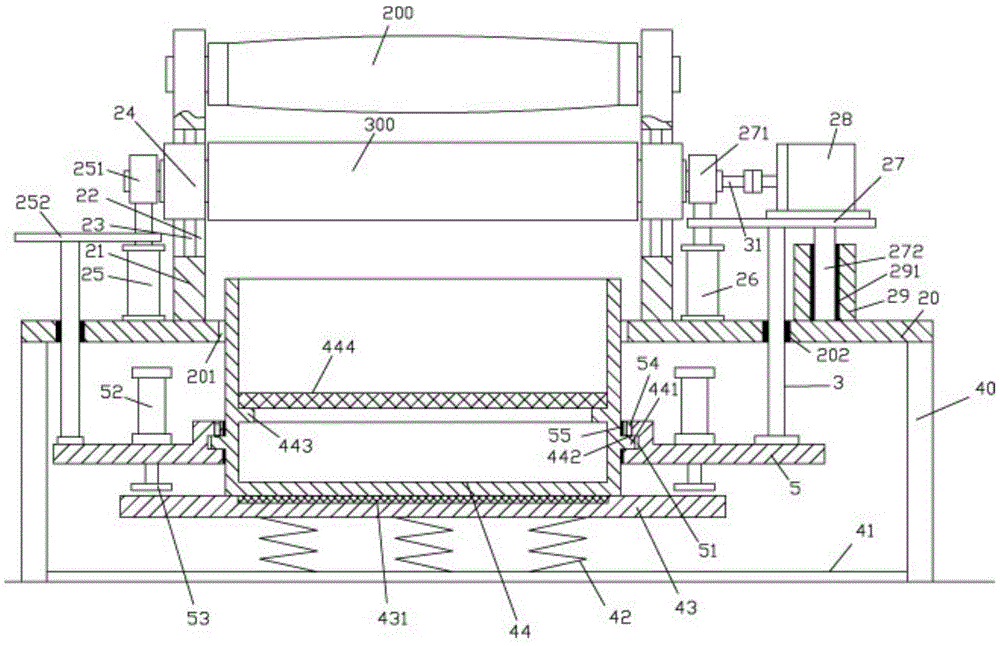

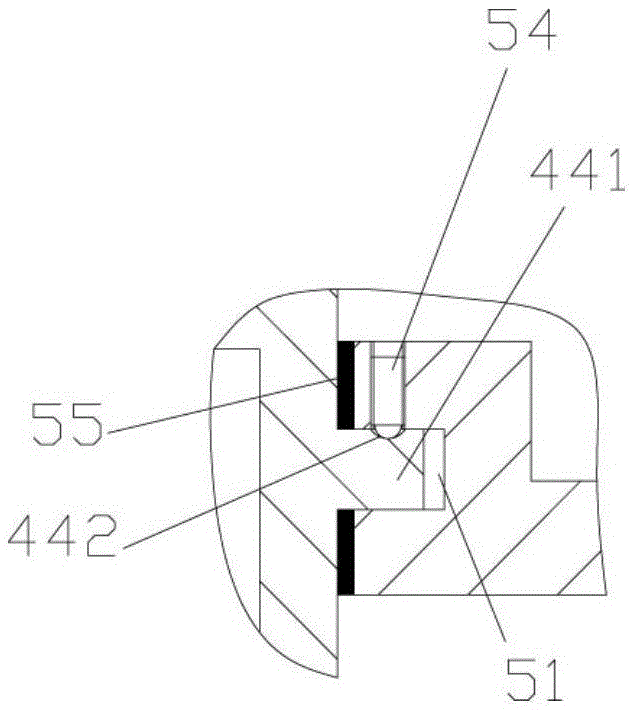

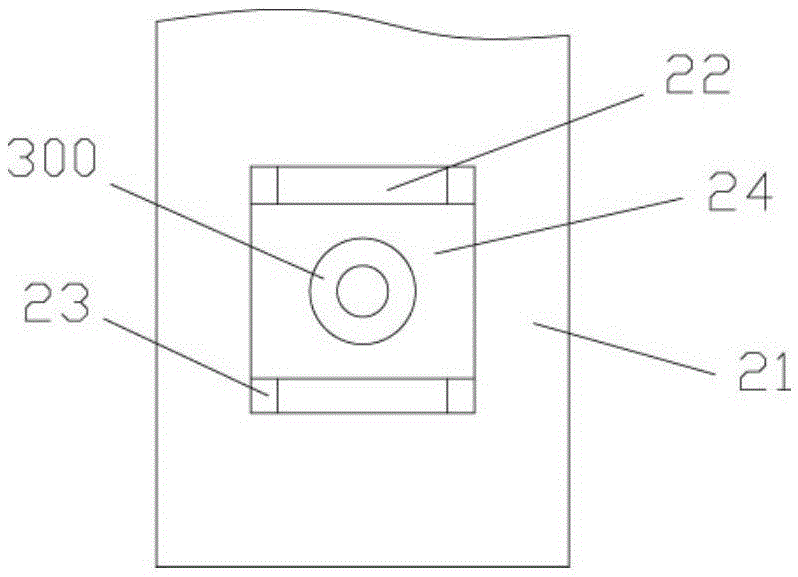

[0018] Examples, see e.g. Figure 1 to Figure 3 As shown, a cloth rolling mill with a water liquid collecting device includes a roll 200 and a horizontal roll 300, the two ends of the roll 200 are hinged at the upper part of the two vertical support plates 21 of the frame 20, and the two vertical The bottom of the support plate 21 has a moving through groove 22, and the two inner side walls of the moving through groove 22 have position-limiting raised strips 23. In the vertical groove 241 that has on the side wall of the moving block 24, the two ends of the horizontal roller 300 are hinged on the corresponding moving block 24, and the left pushing oil cylinder 25 and the right pushing oil cylinder 26 are fixed on the bottom plate of the frame 20. A left connecting plate 252 is fixed on the push rod of the push oil cylinder 25, and a connecting portion 251 is fixed on the left connecting plate 252. , the adjustment plate 27 is fixed with a right connecting part 271 and a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com