Bidirectional test device and test method for single-shaft material test machine

A material testing machine and testing device technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, and can solve the problems of imperfect accurate measurement and inability to directly obtain the stress-strain relationship curve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

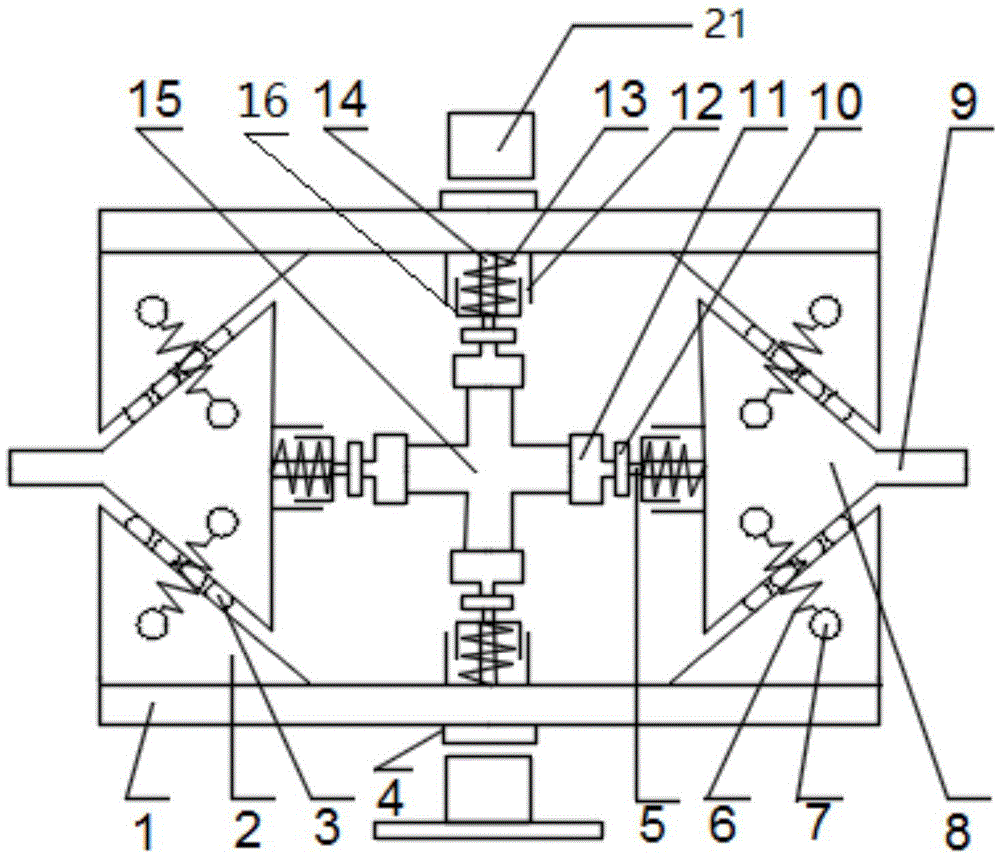

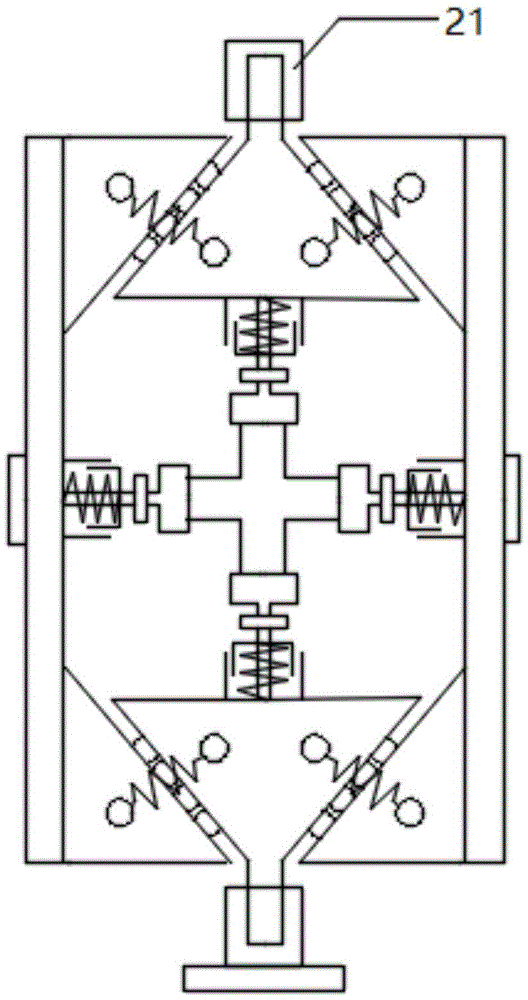

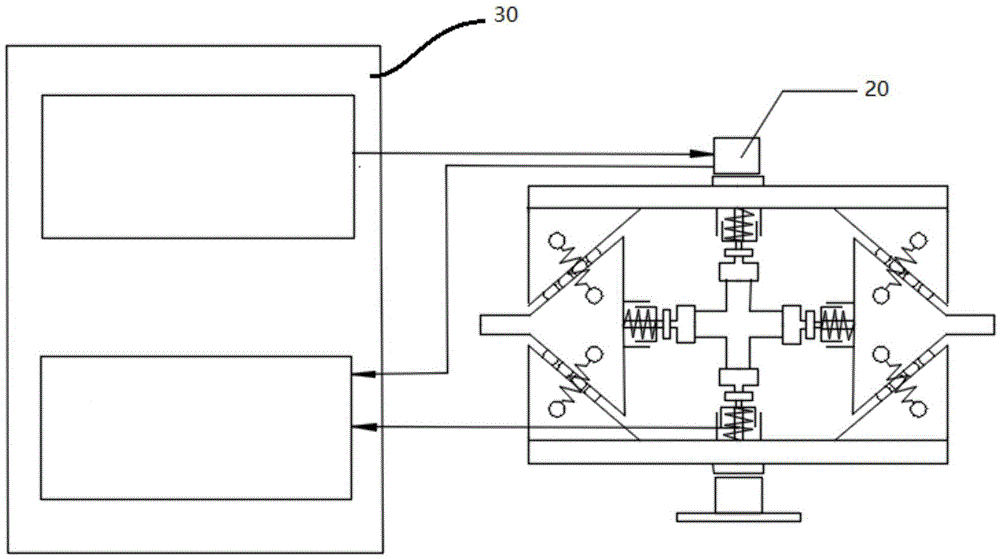

[0029] Such as figure 1 As shown, the bidirectional testing device of one embodiment of the present invention includes a frame for clamping the sample 15 in both directions up and down, and a slide block 8 for clamping the sample 15 in the left and right directions, and measuring the sample 15 Measuring device for the degree of deformation after force in four directions.

[0030] The frame includes two side frames 1 oppositely arranged, and opposite ends of the two side frames 1 are respectively provided with relatively protruding right-angled triangular end wings 2; And the hypotenuses of the two end wings 2 correspond to each other.

[0031] There are two slide blocks 8 and they are respectively clamped and fixed between the two side frames 1 by the end wings 2 at both ends of the two side frames 1 .

[0032] The measuring device includes measuring springs 13 installed on the side of the two side frames 1 and the two sliders 8 facing the sample installation space, and disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com