Fishing rod stiffness measuring instrument and measurement method

A fishing rod stiffness and measurement method technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of not quantifying the physical characteristics of fishing rods, lack of objectivity, etc., to shorten the research and development cycle, ensure consistency, and have a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

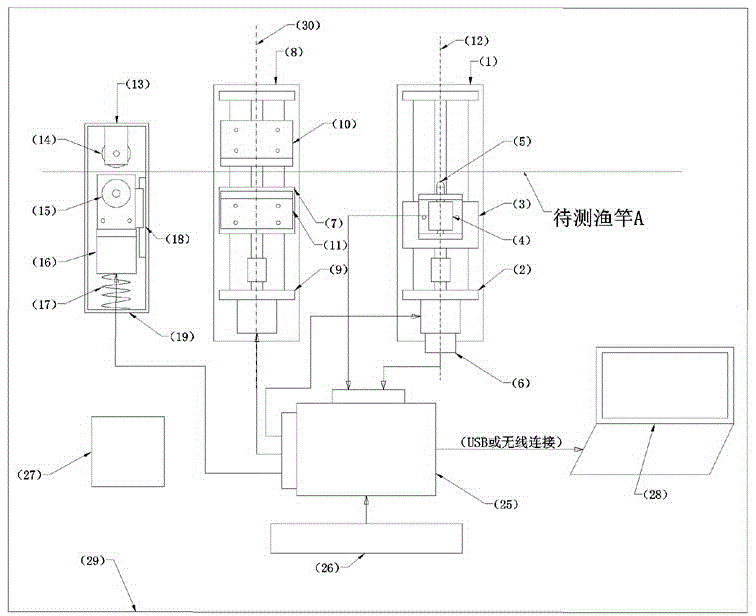

[0024] Such as figure 1 As shown, the fishing rod stiffness measuring instrument involved in the present invention includes a main frame 29, on which a testing machine assembly 1, a fishing rod restraint assembly, a signal control and processing circuit board 25, a control panel 26, a power supply 27 and display, storage and output device 28.

[0025] Wherein said testing machine assembly 1 comprises a first belt motor slide table 2, a displacement sensor 6 is arranged on said first belt motor slide table 2, and a first sliding body is also arranged on said first belt motor slide table 2 3. The first sliding body 3 is provided with a pressure sensor 4 , and the pressure sensor 4 is provided with a pressure sensor probe 5 . The first motorized slide table 2 is powered by the power supply 27 and controlled by the signal control and processing circuit board 25; the pressure sensor 4 and displacement sensor 6 are connected to the signal control and processing circuit board 25 , ...

Embodiment 2

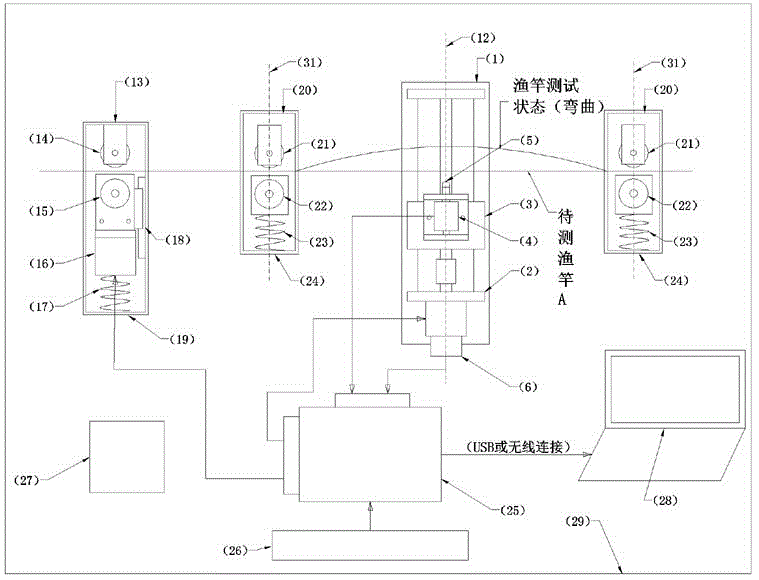

[0036] Such as figure 2 As shown, the fishing rod stiffness measuring instrument involved in the present invention includes a main frame 29, on which a testing machine assembly 1, a fishing rod restraint assembly, a signal control and processing circuit board 25, a control panel 26, a power supply 27 and display, storage and output device 28.

[0037] In this embodiment, except for the fishing rod restraint assembly, other structures and working principles are the same as those in Embodiment 1, and will not be repeated here. In this embodiment, the fishing rod restraint assembly adopts two second fishing rod restraint assemblies 20, and the two second fishing rod restraint assemblies 20 are symmetrically arranged on the testing machine axis 12 of the testing machine assembly 1. Test the left and right sides of machine assembly 1. The second fishing rod restraint assembly 20 includes a restraint block support 24, a fixed wheel 21 is provided at the upper end of the restraint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com