Device for automatically detecting inserting and extracting force of connector

An automatic detection and connector technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of lack of scientific basis, quality problems of electrical equipment, and different detection standards of plugging force, so as to save human resources and eliminate leakage The effect of inspection and improvement of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

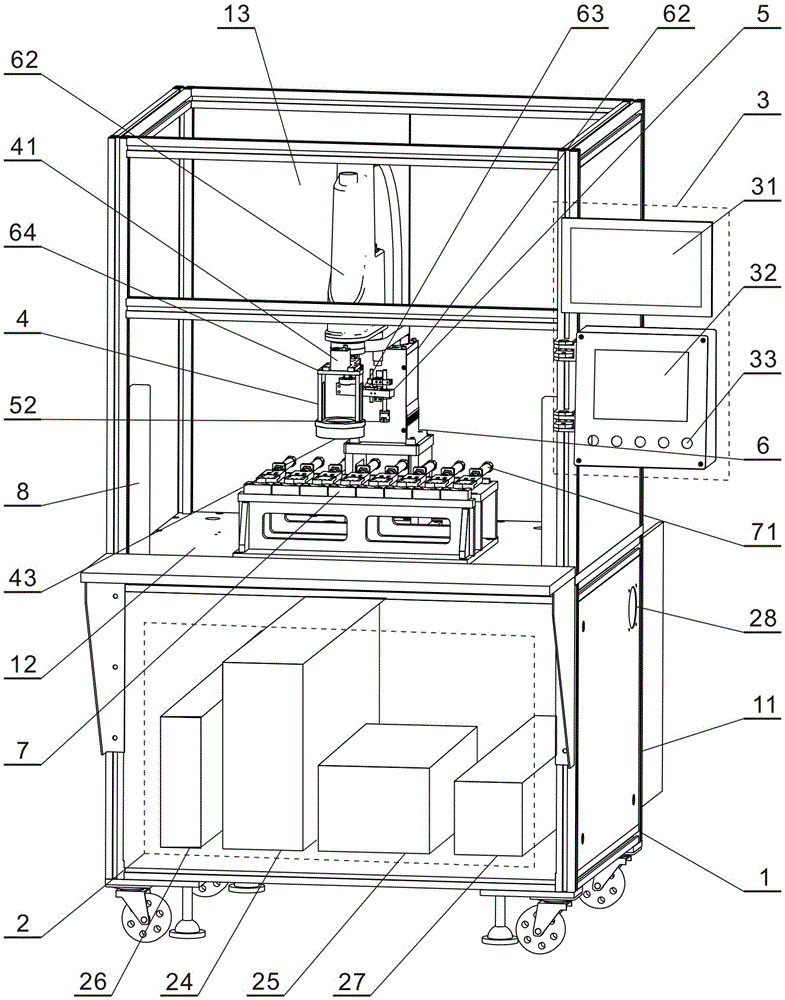

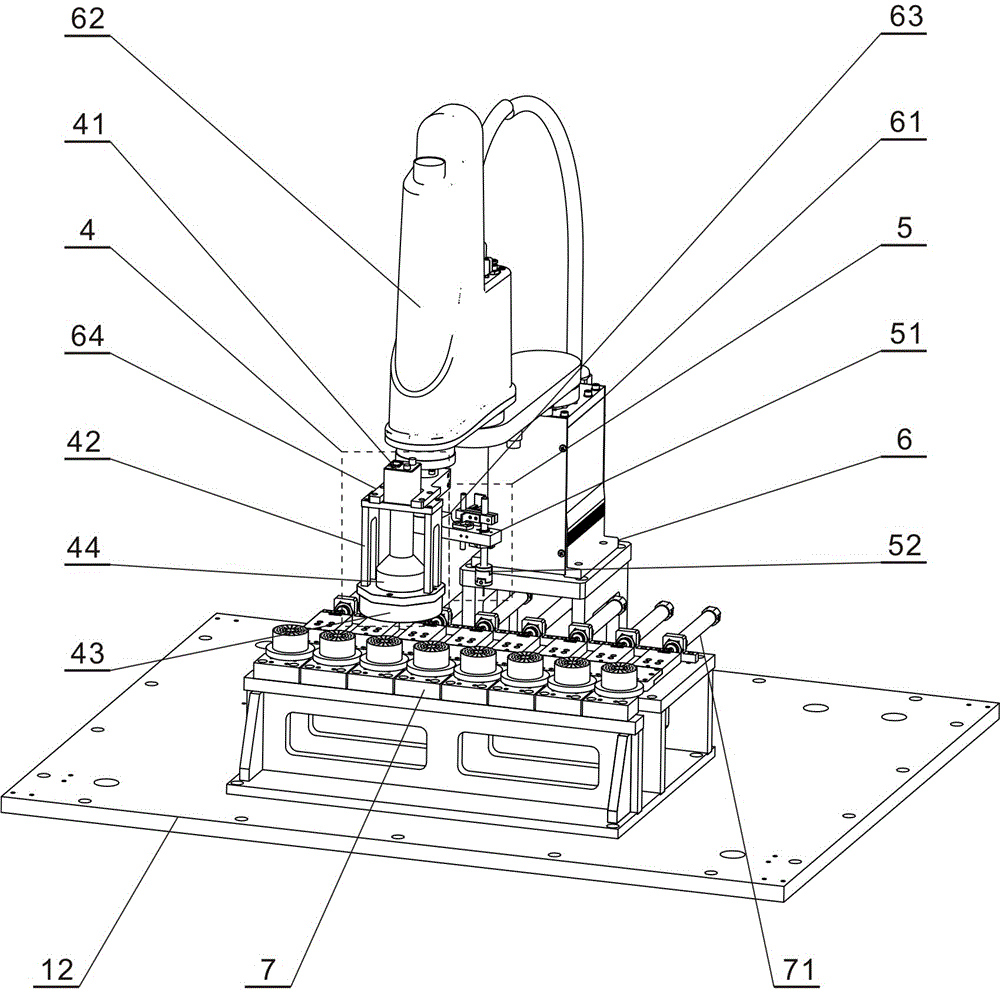

[0017] refer to figure 1 , figure 2 , the present invention includes a device for automatically detecting the plugging force of a connector, characterized in that it includes:

[0018] A cabinet 1 provided with a lower support 11, a table top 12 and a cover 13, and the lower support 11 is arranged below the table 12, and the cover 13 is arranged above the table 12;

[0019] An electrical control cabinet 2 provided with a computer 24, a mechanical arm driver 25, a PLC controller 26, a solenoid valve control driver 27 and a fan 28;

[0020] One is provided with the man-machine interface 3 of computer display screen 31, touch screen 32 and control interface 33;

[0021] One is provided with the image detection mechanism 4 of industrial camera 41, camera support 42, lens 44, ring light source 43, and industrial camera 41, lens 44 and ring light source 43 are arranged on the camera support 42 successively;

[0022] One is provided with a sensor bracket 51, on which is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com