Telephoto lens

A lens and lens technology, which is applied in the field of telephoto lenses, can solve the problems of unfavorable lens miniaturization, which is not conducive to obtaining clear images, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

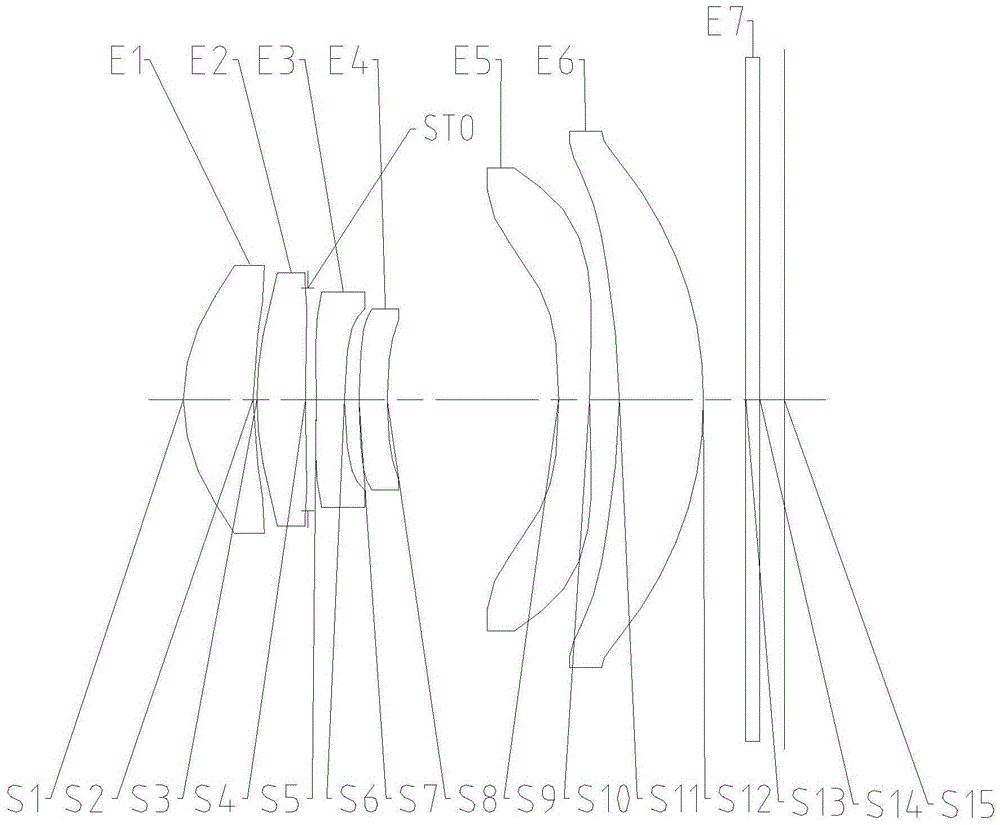

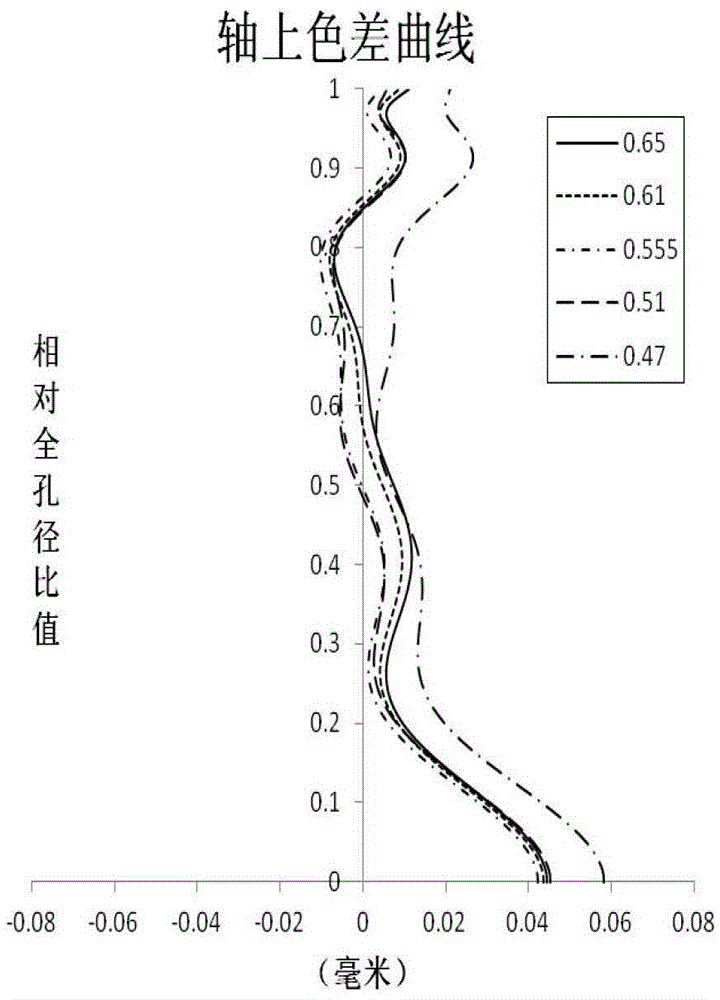

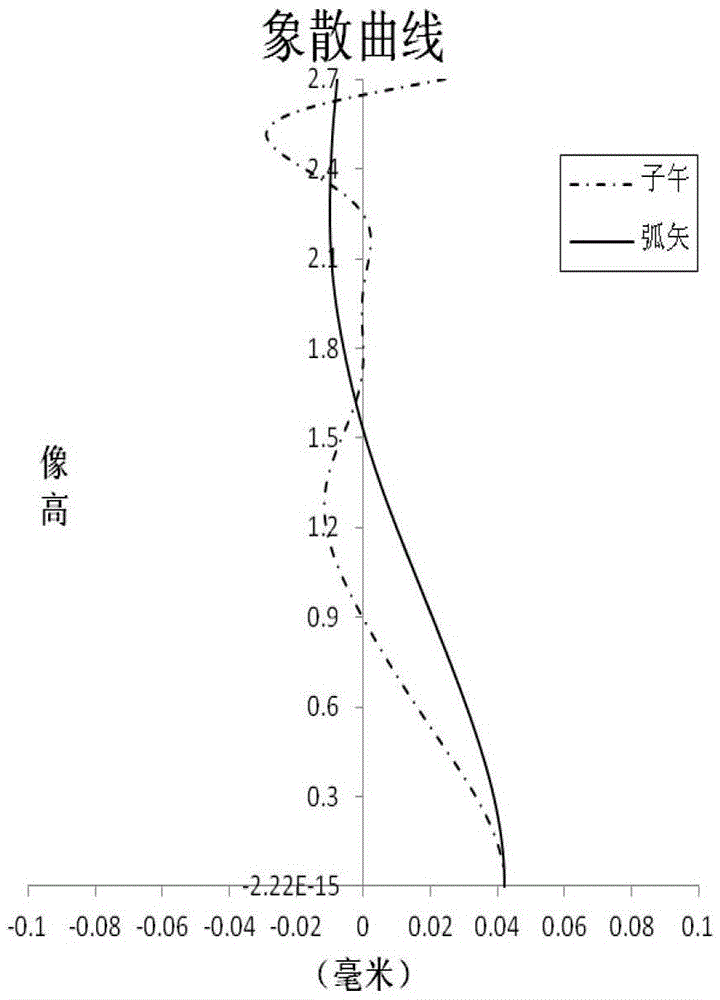

[0088] Please combine Figure 1 to Figure 5 , in Example 1, the telephoto lens satisfies the conditions of the following tables 1-3:

[0089] Table 1

[0090] face number

radius of curvature

thickness

Material

Conic coefficient

OBJ

sphere

infinity

infinity

--

--

S1

Aspherical

1.3683

0.5427

1.544 / 56.11

0.1346

S2

Aspherical

3.1548

0.0300

--

1.4580

S3

Aspherical

2.4634

0.3793

1.544 / 56.11

-3.3809

S4

Aspherical

-96.5945

0.0192

--

-73.5631

STO

sphere

infinity

0.0638

--

--

S5

Aspherical

-8.0667

0.2200

1.651 / 21.52

3.8953

S6

Aspherical

2.9416

0.1128

--

-10.4022

S7

Aspherical

3.4352

0.2200

1.651 / 21.52

-42.4558

S8

Aspherical

3.1394

1.3362

--

-98.9363

S9

Aspheric...

Embodiment 2

[0097] Please combine Figure 6 ~ Figure 10 , in Embodiment 2, the telephoto lens satisfies the conditions of the following tables 4-6:

[0098] Table 4

[0099] face number

radius of curvature

thickness

Material

Conic coefficient

OBJ

sphere

infinity

infinity

--

--

S1

Aspherical

1.2507

0.7331

1.544 / 56.11

-0.0694

S2

Aspherical

-18.2976

0.0777

--

-57.6376

STO

sphere

infinity

0.0000

--

--

S3

Aspherical

-11.6363

0.2300

1.651 / 21.52

-51.8429

S4

Aspherical

3.3249

0.3000

--

-98.9969

S5

Aspherical

-100.0933

0.2756

1.544 / 56.11

-81.1740

S6

Aspherical

-76.3272

0.2406

--

6.7203

S7

Aspherical

-5.6966

0.2300

1.544 / 56.11

19.4373

S8

Aspherical

-314.7117

0.9854

--

-99.0000

...

Embodiment 3

[0105] Please combine Figure 11 to Figure 15 , in Embodiment 3, the telephoto lens satisfies the conditions of the following tables 7-9:

[0106] Table 7

[0107]

[0108]

[0109] Table 8

[0110] face number

A4

A6

A8

A10

A12

A14

A16

S1

-1.4143E-02

-5.9744E-02

1.4002E-01

-3.1357E-01

3.6254E-01

-2.3517E-01

5.9057E-02

S2

-2.9228E-02

-2.8728E-01

1.0566E+00

-2.0159E+00

1.9522E+00

-9.4720E-01

1.8648E-01

S3

1.0861E-02

-2.9759E-01

1.2297E+00

-2.2804E+00

2.0119E+00

-8.1476E-01

1.2404E-01

S4

8.6866E-02

1.9960E-02

-3.4133E-01

7.7217E-01

-1.2140E+00

1.0161E+00

-3.2575E-01

S5

1.8403E-01

9.6861E-04

-9.8330E-01

3.5935E+00

-5.6842E+00

4.2841E+00

-1.2966E+00

S6

4.2255E-02

3.8988E-01

-2.2929E+00

9.3146E+00

-1.6720E+01

1.6679E+01

-7.6297E+00

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com