Sunglasses for myopia and method of making the same

A sun and lens technology, applied in the field of its preparation, myopia sun lens, can solve the problems of poor uniformity of lens coloring, certain period of production, uneven coloring, etc., and achieve the effects of good vision protection, high hardness and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

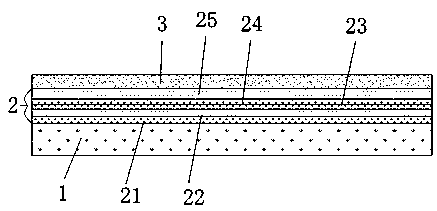

[0035] Such as figure 2 As shown, the myopia sunglass includes a substrate 1 made of THC400-boron phenolic resin carbon as the main raw material, an anti-blue light layer 2, and a dyed hardened layer 3, wherein the anti-blue light layer consists of dyed hardened layers from the base sheet to the dyed hardened layer sequentially. layer set by the first SiO 2 Film layer 21, ZrO 2 Film layer 22, the second SiO 2 Film layer 23, Ti 2 o 3Film layer 24, In 2 o 3 Film layer 25, the dyeing and hardening layer 3 adopts the hardening solution immersion plating with methanol as a solvent, and the solute in the hardening solution includes 28-36wt% dyeing agent, and the hardening solution immersion plating process is Finish at 9-12°C ambient temperature.

[0036] In the above embodiments, the thickness of the dyed hardening layer is 2.2-3 μm. First SiO 2 The thickness of the film layer is 1.5μm, ZrO 2 The thickness of the film layer is 0.3 μm, the second SiO 2 The thickness of t...

Embodiment 2

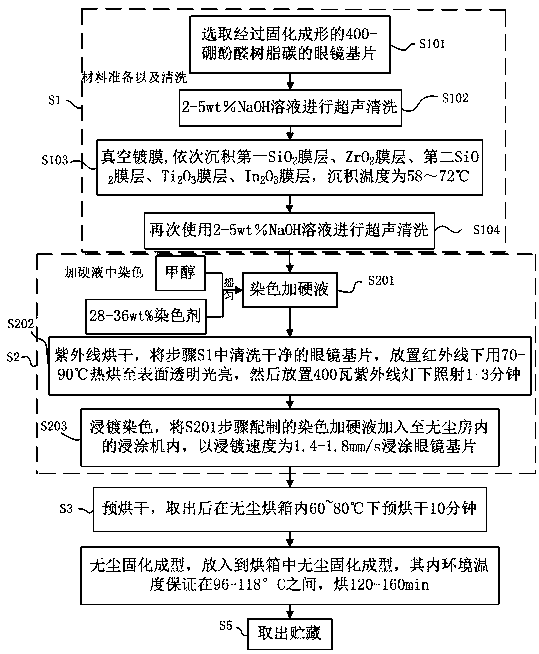

[0038] Such as figure 1 As shown, select the spectacle substrate of THC400-boron phenolic resin carbon that has been cured and formed, and prepare a dyeing agent according to the light transmittance of 15%. The specific steps are as follows:

[0039] S1: Material preparation and cleaning;

[0040] S101: Select the spectacle substrate of cured and formed THC400-boron phenolic resin carbon;

[0041] S102: and use 3wt% NaOH solution to perform ultrasonic cleaning;

[0042] S103: Using a vacuum coating machine, sequentially deposit the first SiO on the surface of the hard coating layer 2 Film layer, ZrO 2 film layer, the second SiO 2 film layer, Ti 2 o 3 Film layer, In 2 o 3 film layer, the deposition temperature is 70°C;

[0043] S104: Use 2.5wt% NaOH solution for ultrasonic cleaning again, the temperature is 35°C, and the treatment time is 10-15 minutes; then rinse with pure water, the rinsing temperature is 35°C, and the drying temperature is 70°C;

[0044] S2: Dyeing...

Embodiment 3

[0051] Such as figure 1 As shown, select the spectacle substrate of THC400-boron phenolic resin carbon that has been cured and formed, and prepare a dyeing agent according to the light transmittance of 85%. The specific steps are as follows:

[0052] S1: Material preparation and cleaning;

[0053] S101: Select the spectacle substrate of cured and formed THC400-boron phenolic resin carbon;

[0054] S102, and use 4.8wt% NaOH solution to perform ultrasonic cleaning;

[0055] S103: Using a vacuum coating machine, sequentially deposit the first SiO on the surface of the hard coating layer 2 Film layer, ZrO 2 film layer, the second SiO 2 film layer, Ti 2 o 3 Film layer, In 2 o 3 film layer, the deposition temperature is 65°C;

[0056] S104: Use 4.6wt% NaOH solution to perform ultrasonic cleaning again at a temperature of 35° C. for 13 minutes; then rinse with pure water at a temperature of 35° C. and a drying temperature of 70° C.;

[0057] S2: Dyeing in the hardening solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com