Electronic product case and manufacturing method thereof

A technology of electronic products and manufacturing methods, which is applied in the direction of electrical equipment casings/cabinets/drawers, electrical components, metal casings, etc., and can solve problems that affect product durability and poor surface protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

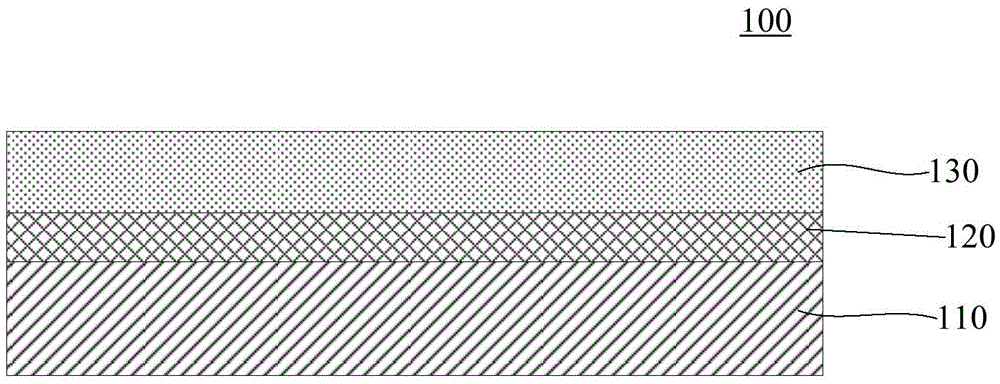

[0032] Please refer to figure 1 , the electronic product casing 100 of the first embodiment includes an aluminum alloy main body layer 110 , an anodized layer 120 and a flash point effect layer 130 . Wherein, the anodized layer 120 is disposed on the aluminum alloy body layer 110 . The flash point effect layer 130 is provided on the anodized layer 120 . The flash point effect layer 130 can make the housing 100 of the electronic product have a flash point effect, which is beneficial to improve the appearance effect of the product and enhance user experience.

[0033] In this embodiment, the flash point effect layer 130 is a paint layer doped with flash particles. The flash point effect layer 130 may be one or more layers. When the flash point effect layer 130 is multi-layered, the multi-layer flash point effect layers 130 may be stacked.

[0034] The thickness of the flash point effect layer 130 in this embodiment is 5 μm-30 μm. Wherein, the particle size of the glitter pa...

Embodiment 2

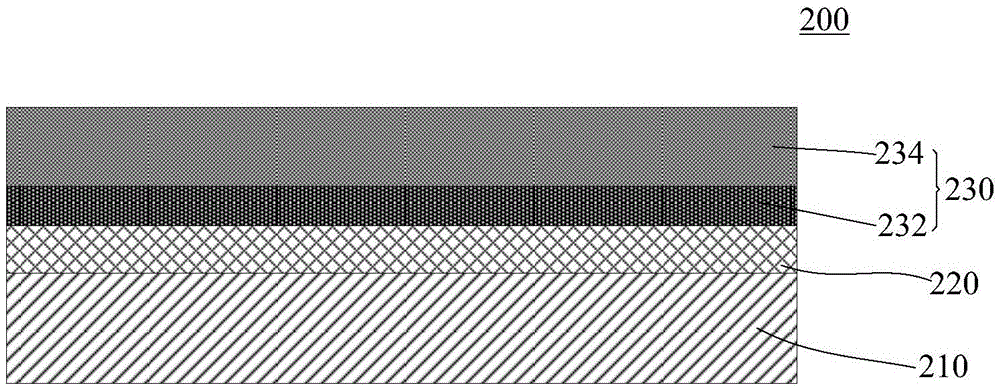

[0055] Please refer to figure 2 , the electronic product case 200 of the second embodiment includes an aluminum alloy main body layer 210 , an anodized layer 220 and a flash point effect layer 230 . Wherein, the anodized layer 220 is disposed on the aluminum alloy body layer 210 . The flash point effect layer 230 is disposed on the anodized layer 220 . The flash point effect layer 230 can make the housing 200 of the electronic product have a flash point effect, which is beneficial to improve the appearance effect of the product and enhance user experience.

[0056] In this embodiment, the flash point effect layer 230 includes a flash particle layer 232 and a paint layer 234 . Both the glitter particle layer 232 and the paint layer 234 can be one or more layers, and the number of the glitter particle layer 232 is the same as that of the paint layer 234 . When both the glitter particle layer 232 and the paint layer 234 have multiple layers, the multiple layers of glitter par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com