Hybrid powertrain systems

A hybrid power and hybrid drive technology, which is applied to hybrid vehicles, power units, electric power units, etc., can solve problems such as different, uneven unsprung weight, shaking of motor generators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

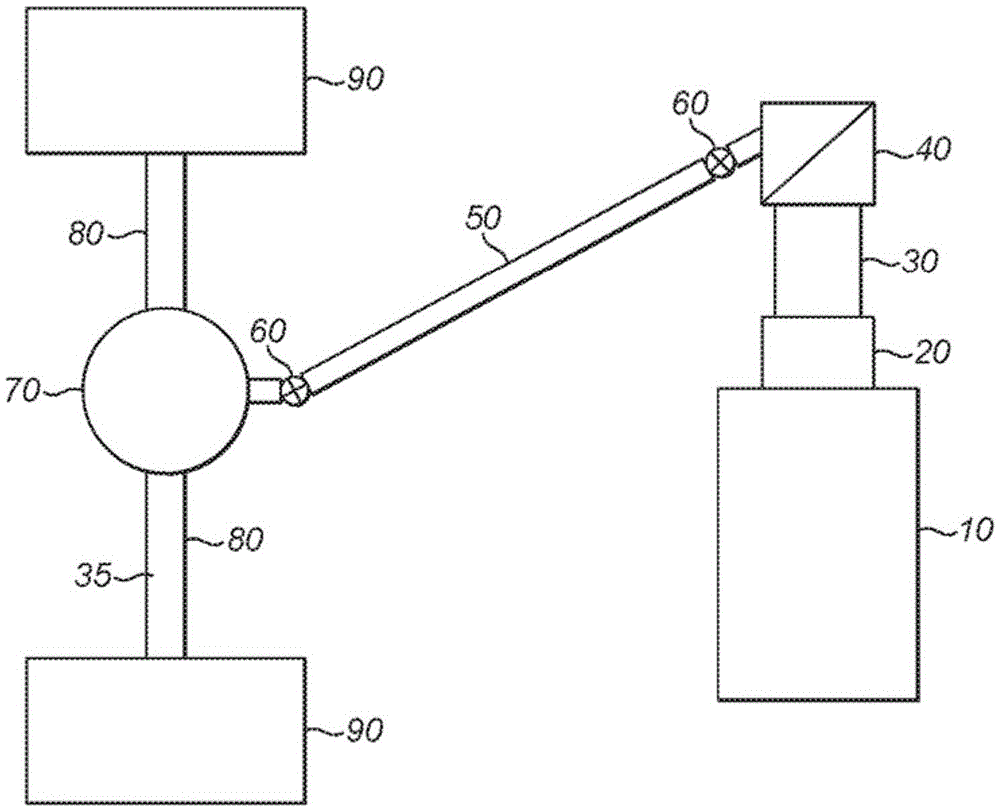

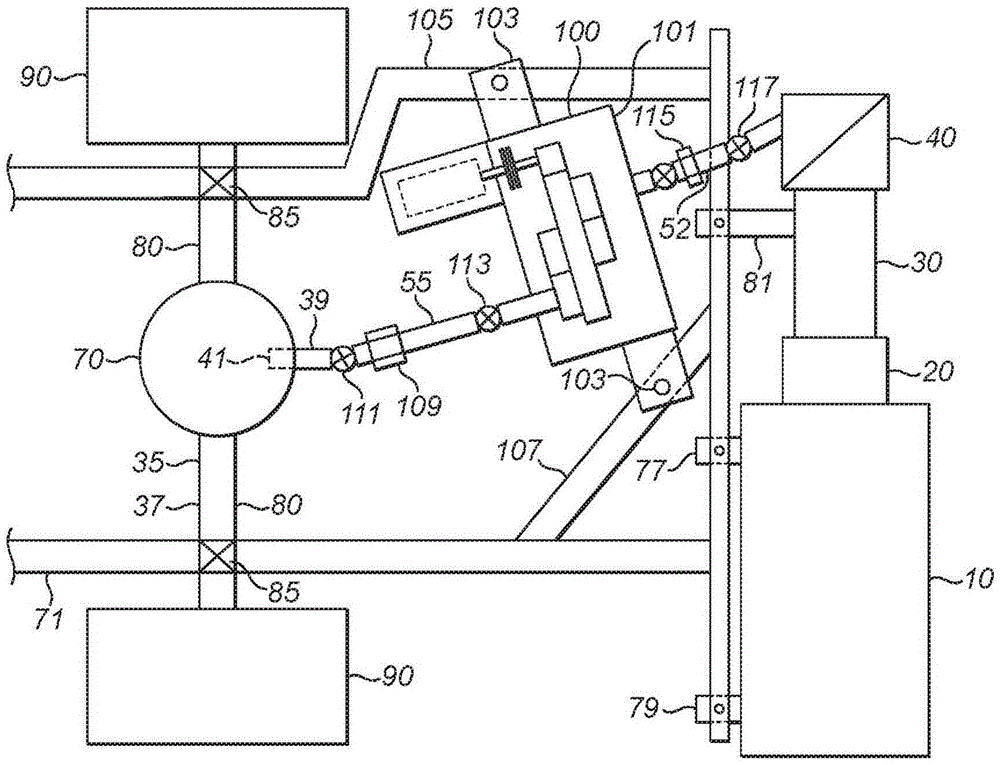

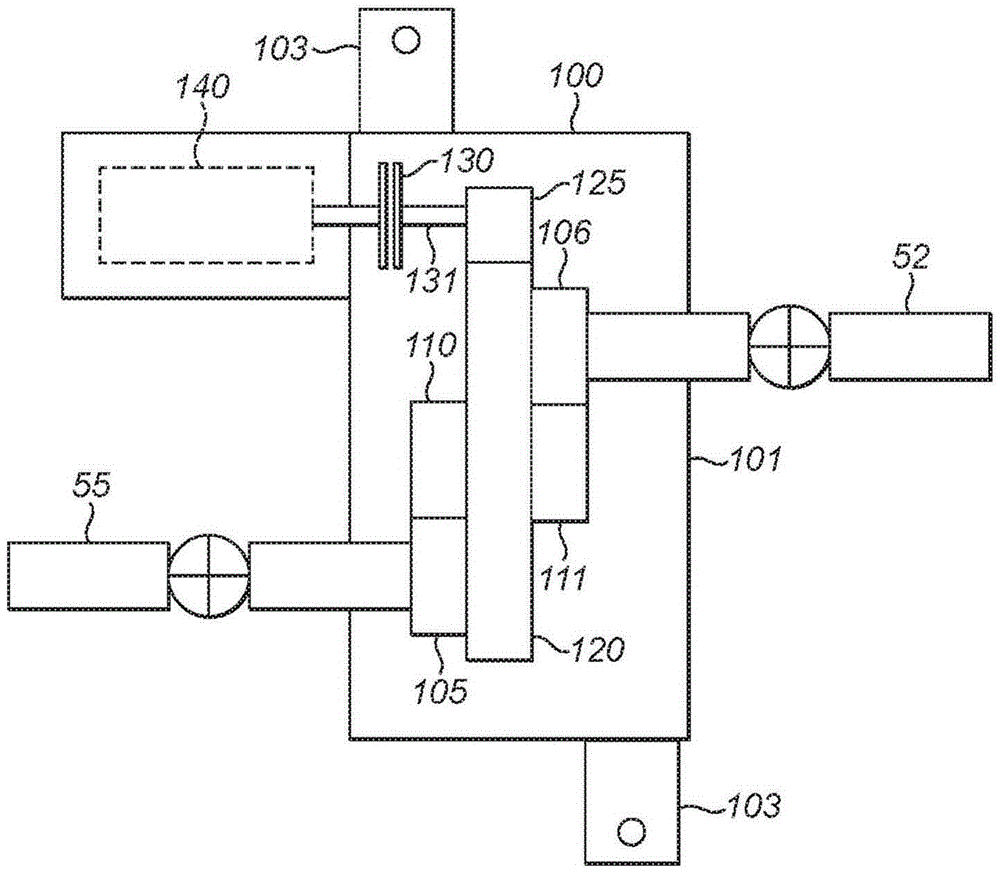

[0061] Such as Figure 5 As shown, a vehicle 5 in the form of a double decker bus has wheels 90, brakes 11, an engine 10 and a hybrid powertrain motor generator 140, wherein the hybrid powertrain motor generator 140 communicates with a mechanical flywheel (or mechanical energy storage components) unit 7 , the vehicle battery or chemical / electrical energy storage 15 and the control system 13 . The motor-generator can send electrical energy to and receive energy from the mechanical flywheel unit 7 . The mechanical flywheel unit 7 may comprise means (not shown) with a further motor-generator for converting electrical energy into mechanical energy by rotating the mechanical flywheel upwards, and subsequently converting the mechanical energy into electrical energy to provide electric power to the motor generator 140 . The motor-generator 140 may comprise a single alternator unit in which the same coils are used for both motoring and generating modes; or the motor-generator 140 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com