Adsorption mechanism

A technology of adsorption mechanism and adsorption surface, applied in the direction of metal processing mechanical parts, clamping, support, etc., can solve problems such as increasing production cost, and achieve the effect of wide use and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

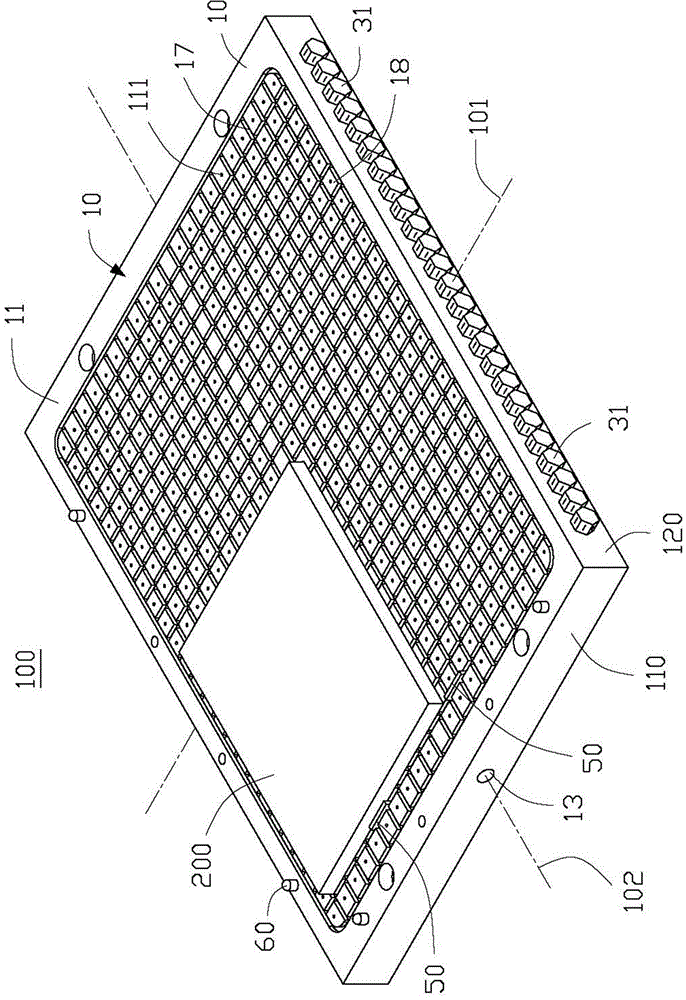

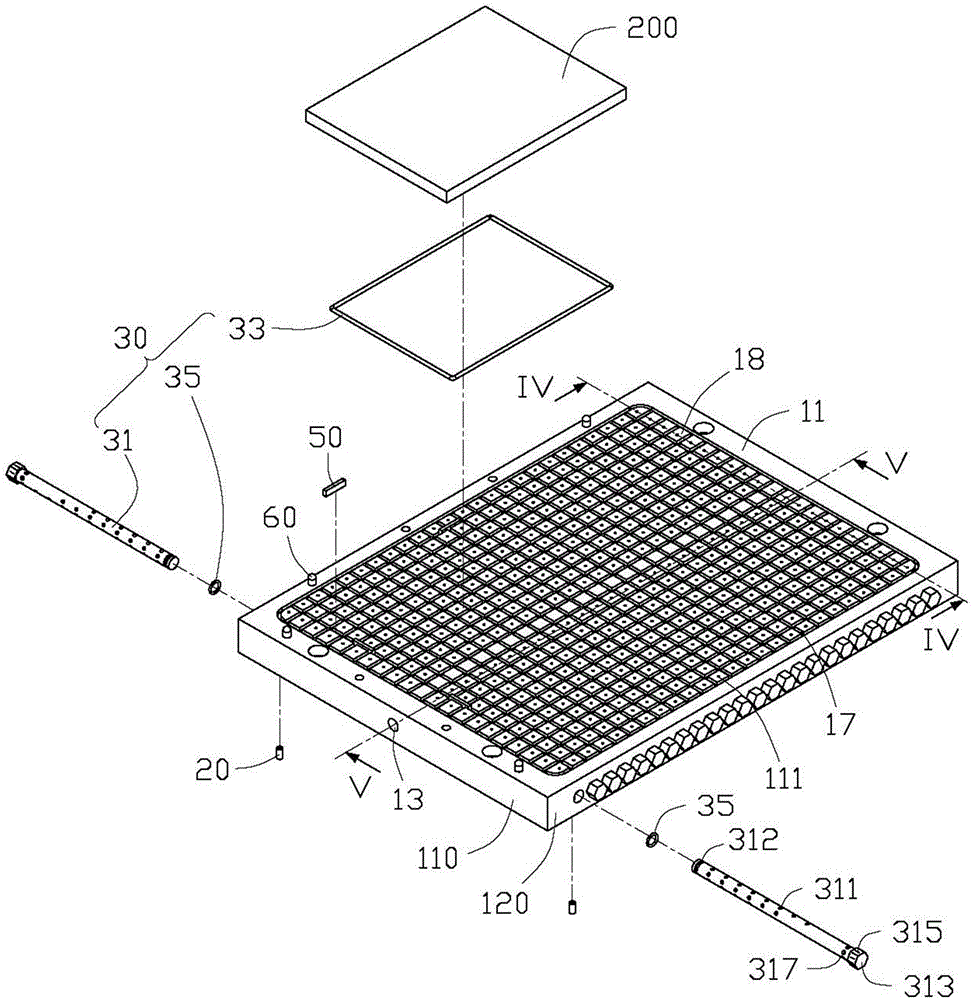

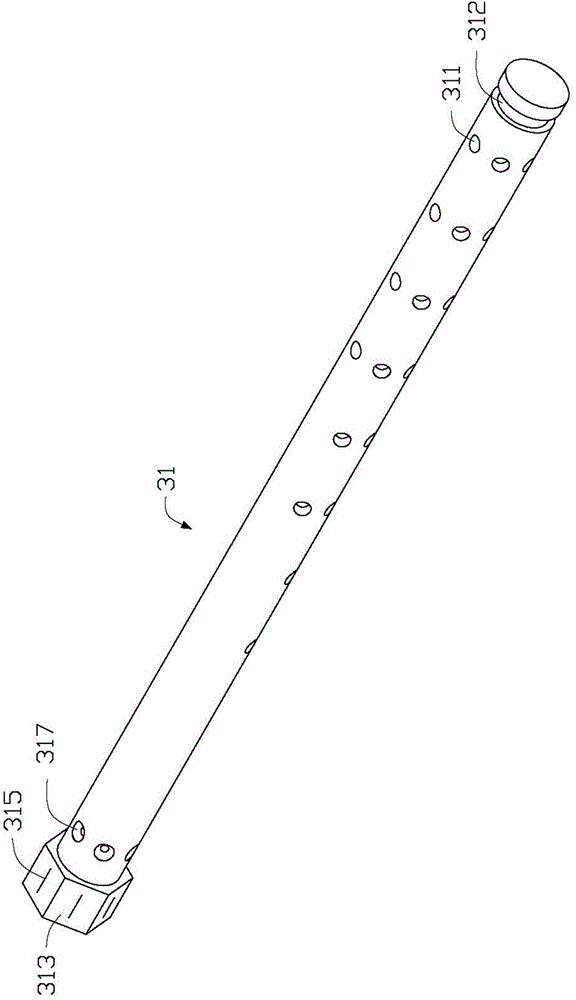

[0014] see figure 1 , the adsorption mechanism 100 of the embodiment of the present invention is used to adsorb and position the workpiece 200 for processing. In this embodiment, the workpiece 200 is an aluminum alloy plate. Please also see figure 2 and image 3 , the adsorption mechanism 100 includes a base body 10 , a control member 30 and a positioning member 50 mounted on the base body 10 .

[0015] Please also see image 3 and Figure 5 , the base body 10 is roughly in the shape of a rectangular block, which includes an adsorption surface 11 , two opposite first side surfaces 110 and two opposite second side surfaces 120 . The first side 110 is disposed on opposite sides parallel to the transverse axis 101 of the first base 10 , and the second side 120 is disposed on both sides parallel to the longitudinal axis 102 of the base 10 . The adsorption surface 11 is perpendicular to the first side 110 and the second side 120 . A plurality of suction holes 111 are spaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com