Petroleum drilling machine multi-mode automatic drilling control method

A technology of automatic drilling and control method, which is applied in the automatic control system of drilling, drilling equipment, earth-moving drilling and mining, etc., can solve the problems of damage efficiency and deviation, etc., and achieve a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below:

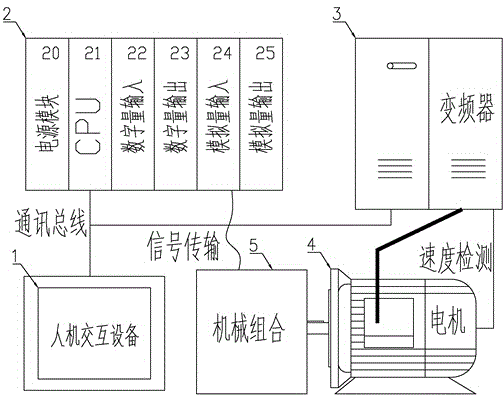

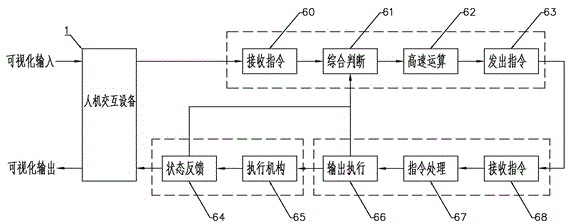

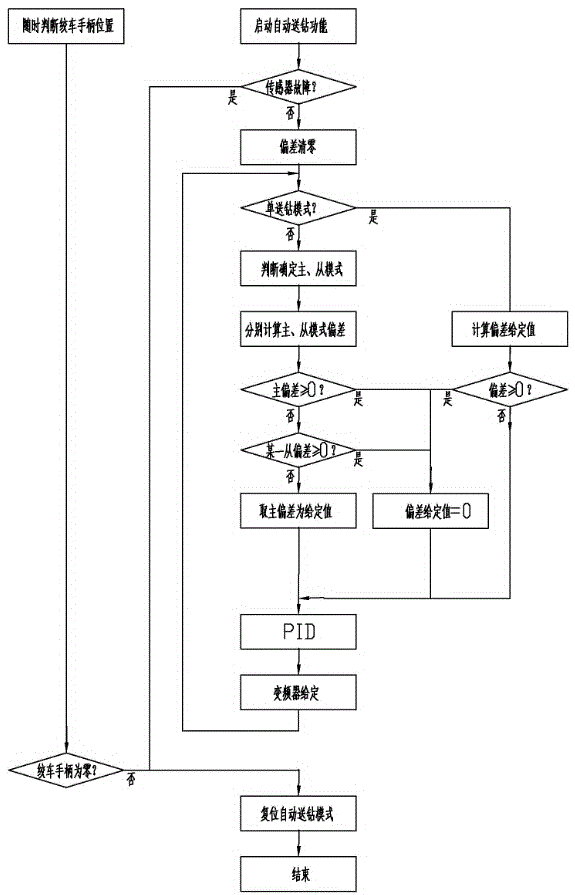

[0030] Such as figure 1 As shown, the multi-mode automatic drilling control method for oil rigs is based on running equipment, including visual human-computer interaction equipment 1, programmable controller 2, frequency converter 3, motor 4, mechanical combination 5 and command transceiver device 6; The visualized human-computer interaction device 1 is connected to the programmable controller 2, the frequency converter 3 and the command sending and receiving device 6 through the bus, the motor 4 is connected to the mechanical combination 5 through transmission, and the programmable controller 2 and the mechanical combination 5 are connected through signal cables for transmission. Status signal, in addition to the power cable connection between the inverter 3 and the motor 4, there is also a connecting cable for the encoder signal; the visual human-computer interaction device 1 is used to receive and transmit the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com