Winding device for hydrogen purification film production

A winding device, hydrogen technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of inability to achieve uniform winding, poor film adhesion, etc., to achieve the effect of promoting lamination and winding Effect improvement, wide-spread effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

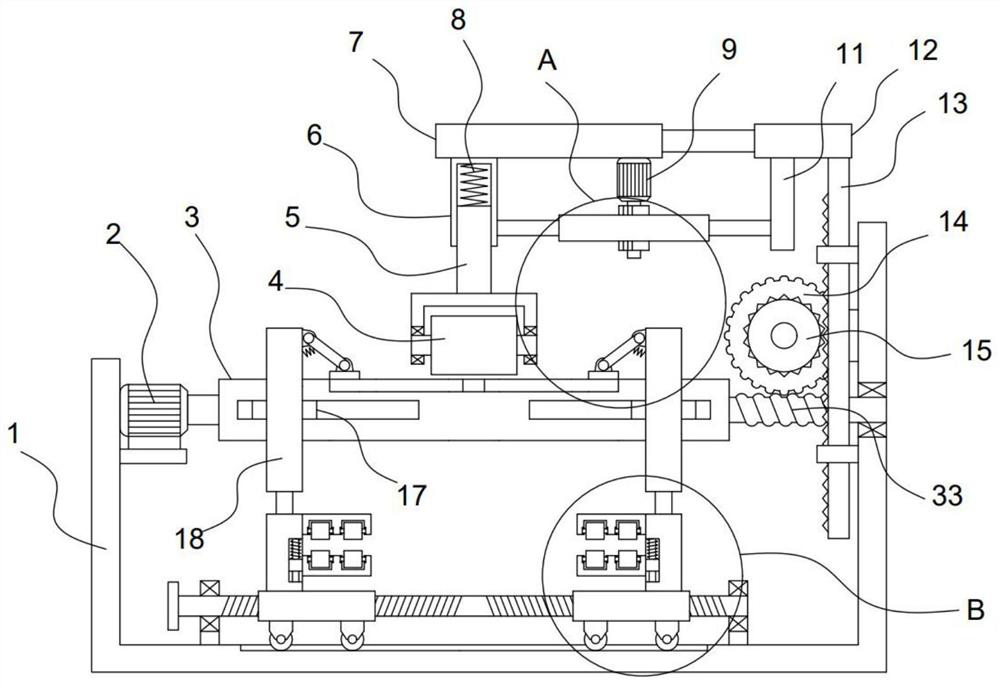

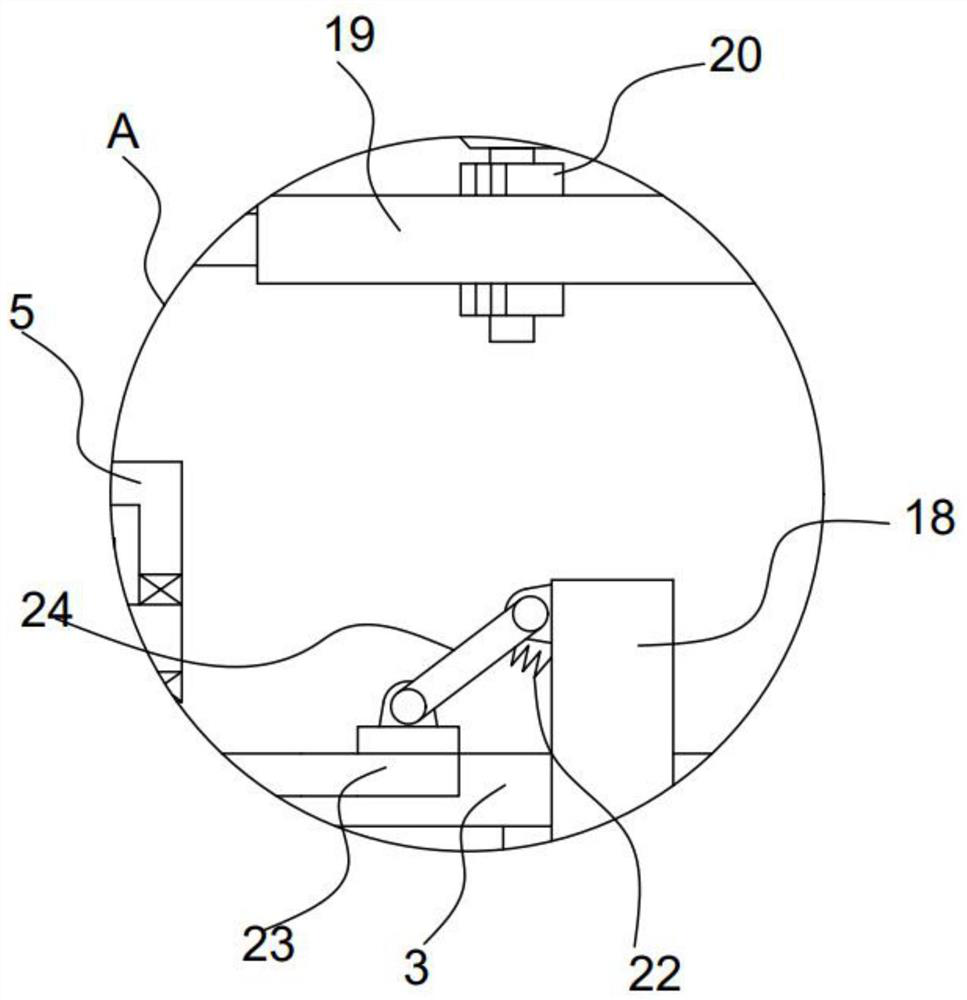

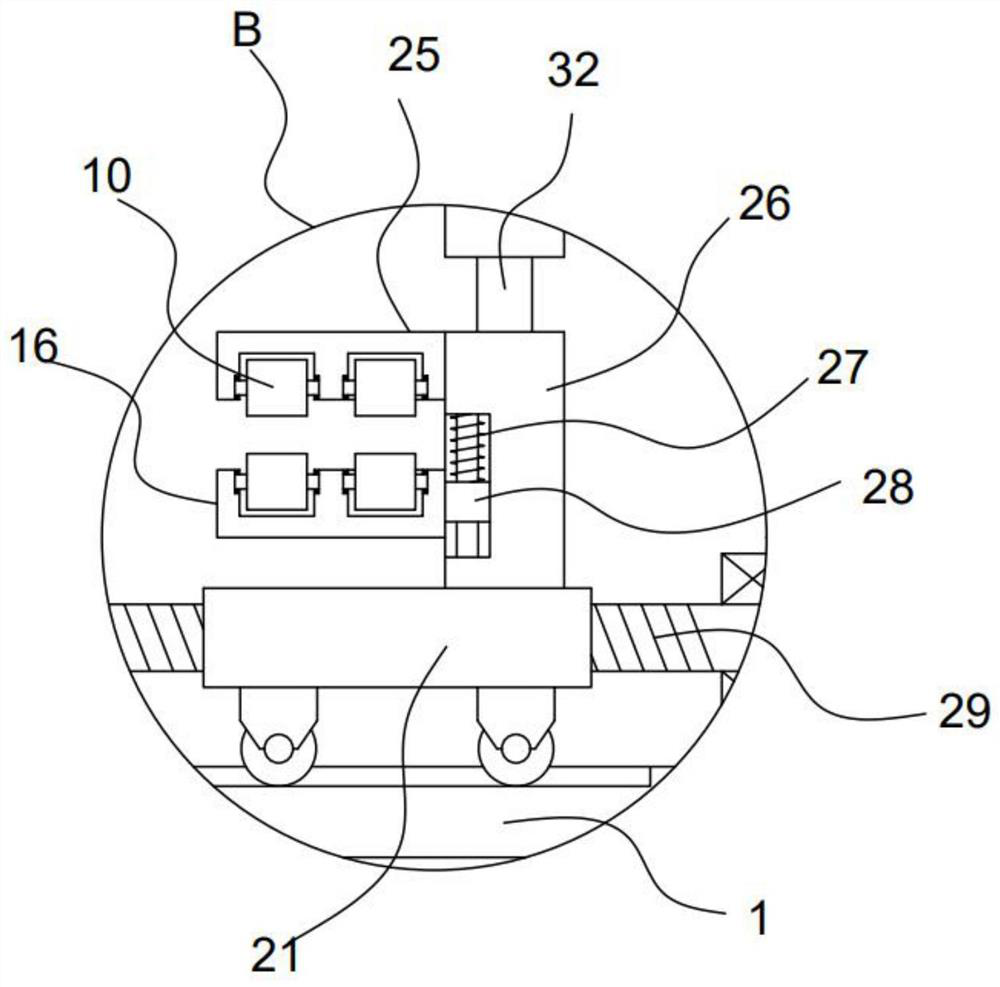

[0024] see Figure 1-5 , a kind of winding device for hydrogen purification film production, comprising a frame 1, a motor I2 is fixed on the frame 1, and the output shaft of the motor I2 is driven to be connected with a winding roller 3 for winding the film. A pair of limit mechanisms are slidably installed on the winding roller 3, the limit mechanism is provided with a clamping mechanism for fixing the film, and the limit mechanism is provided with a smooth stretching mechanism for leveling the film, The frame 1 is horizontally provided with a transverse sleeve 7, and the bottom of the transverse sleeve 7 is provided with a rolling mechanism for rolling the film wound on the take-up roller 3, and the horizontal sleeve 7 is installed horizontally. There is a connecting plate 12, and a translation mechanism for driving the rolling mechanism to move laterally relative to the connecting plate 12 is provided on the transverse sleeve 7.

[0025] The limit mechanism of this device...

Embodiment 2

[0031] On the basis of Embodiment 1, in addition, the rolling mechanism includes a vertical sleeve 6 vertically fixed on the horizontal sleeve 7, a telescopic frame 5 is vertically slidably installed on the vertical sleeve 6, and the telescopic frame 5 rotates A pressure roller 4 abutting against the upper film of the winding roller 3 is installed, and a connection spring 8 is fixedly connected between the telescopic frame 5 and the telescopic frame 5 . The rolling mechanism also includes a worm 33 coaxially fixed with the winding roller 3, the worm 33 is meshed with a worm wheel 14, the worm wheel 14 is coaxially fixed with a transmission gear 15, and the transmission gear 15 is meshed with a vertically arranged vertical shaft. The rack 13, the upper end of the vertical rack 13 is fixedly connected with the connecting plate 12.

[0032] Through the above-mentioned setting, during the process of winding the film by the rotation of the winding roller 3, under the elastic action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com