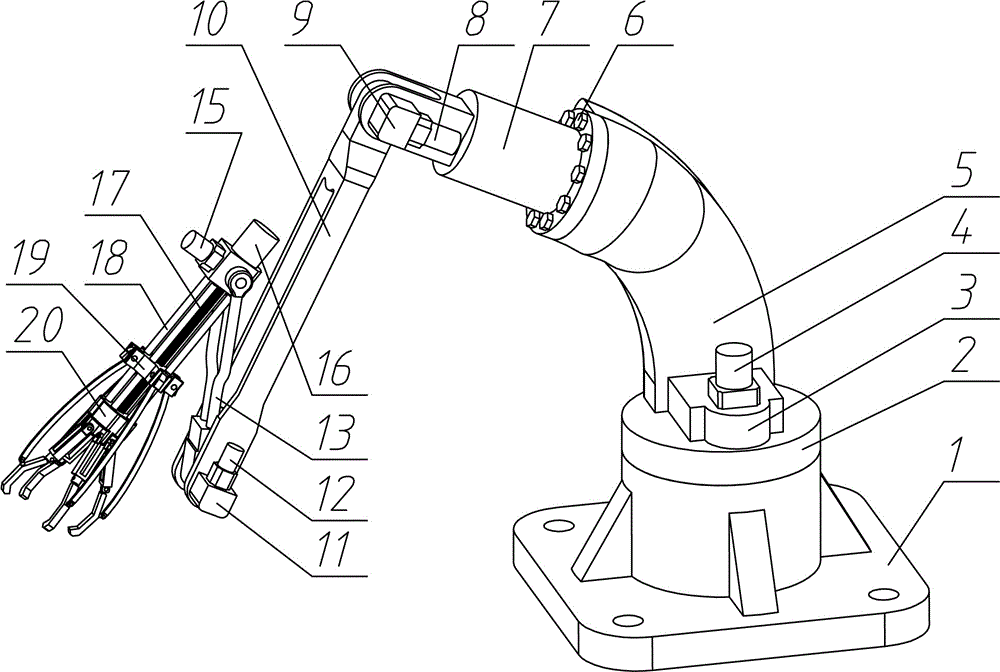

Palletizing robot with grabbing function

A technology of palletizing robots and grabbing manipulators, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as low efficiency, labor cost, and heavy workload, and achieve a large grabbing range and facilitate transportation and storage , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

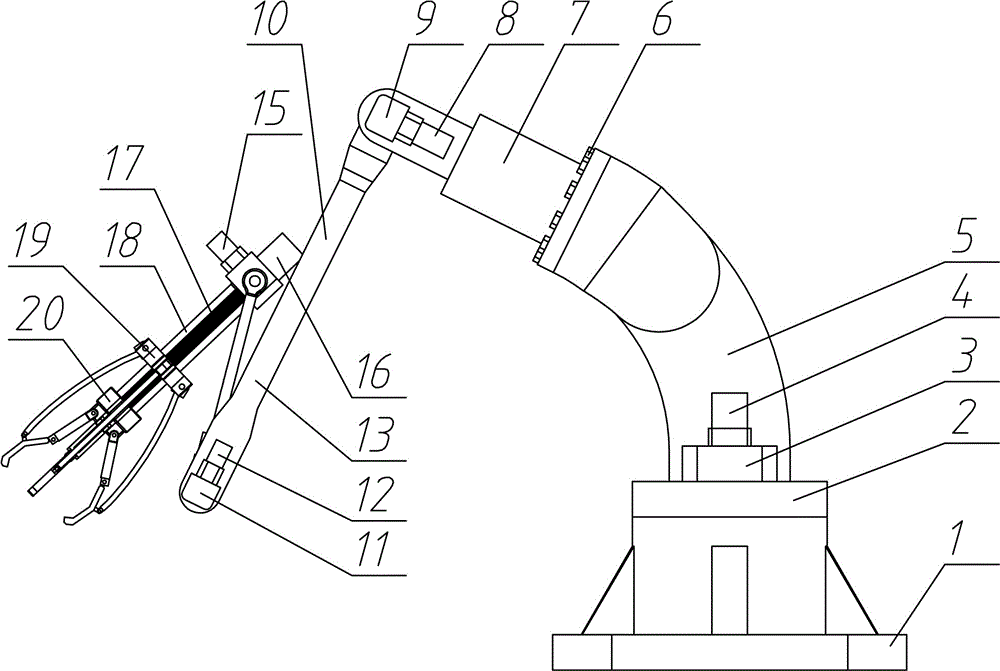

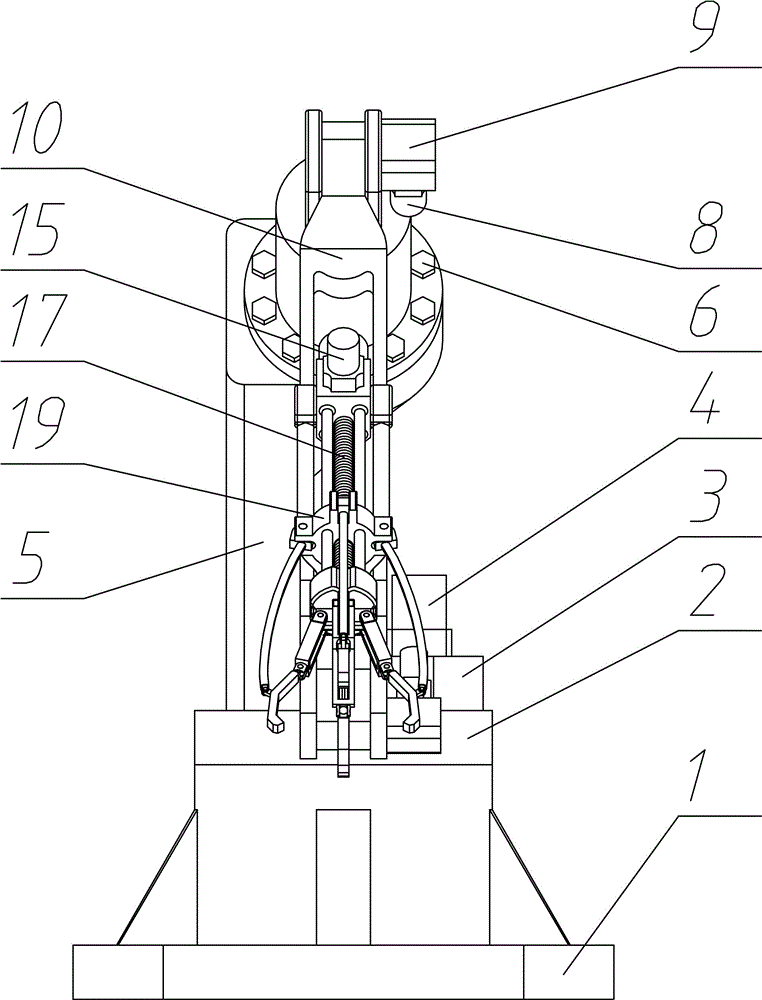

[0032] Such as Figure 1-9 Shown, a kind of palletizing robot with grabbing function, it comprises base 1, and base 1 is positioned and fixedly installed on the workbench by four evenly distributed bolt holes, and rotating disc 2 is installed on base 1, and described rotating The chassis 2 rotates around the central shaft of the base 1, the central shaft is driven by the sun gear of the planetary gear reducer 3, the input shaft of the planetary gear reducer 3 is the sun gear, and the sun gear is driven by the No. 1 AC servo motor 4 of the planetary gear The ring gear is fixedly connected to the base 1, and the rotation of the planetary gear makes the rotating chassis 2 rotate around the center of the sun gear; the No. 1 AC servo motor 4 is installed on the planetary gear reducer 3 through screws, and the two rotate around the center of the base 1 togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com