Bottom gray plate feeding device for box processing

A technology of feeding device and packaging box, which is applied in the direction of transportation and packaging, thin material handling, and object separation, etc. It can solve the problems of reducing processing efficiency and product quality stability, so as to reduce the influence of human factors, Effects of improving stability and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

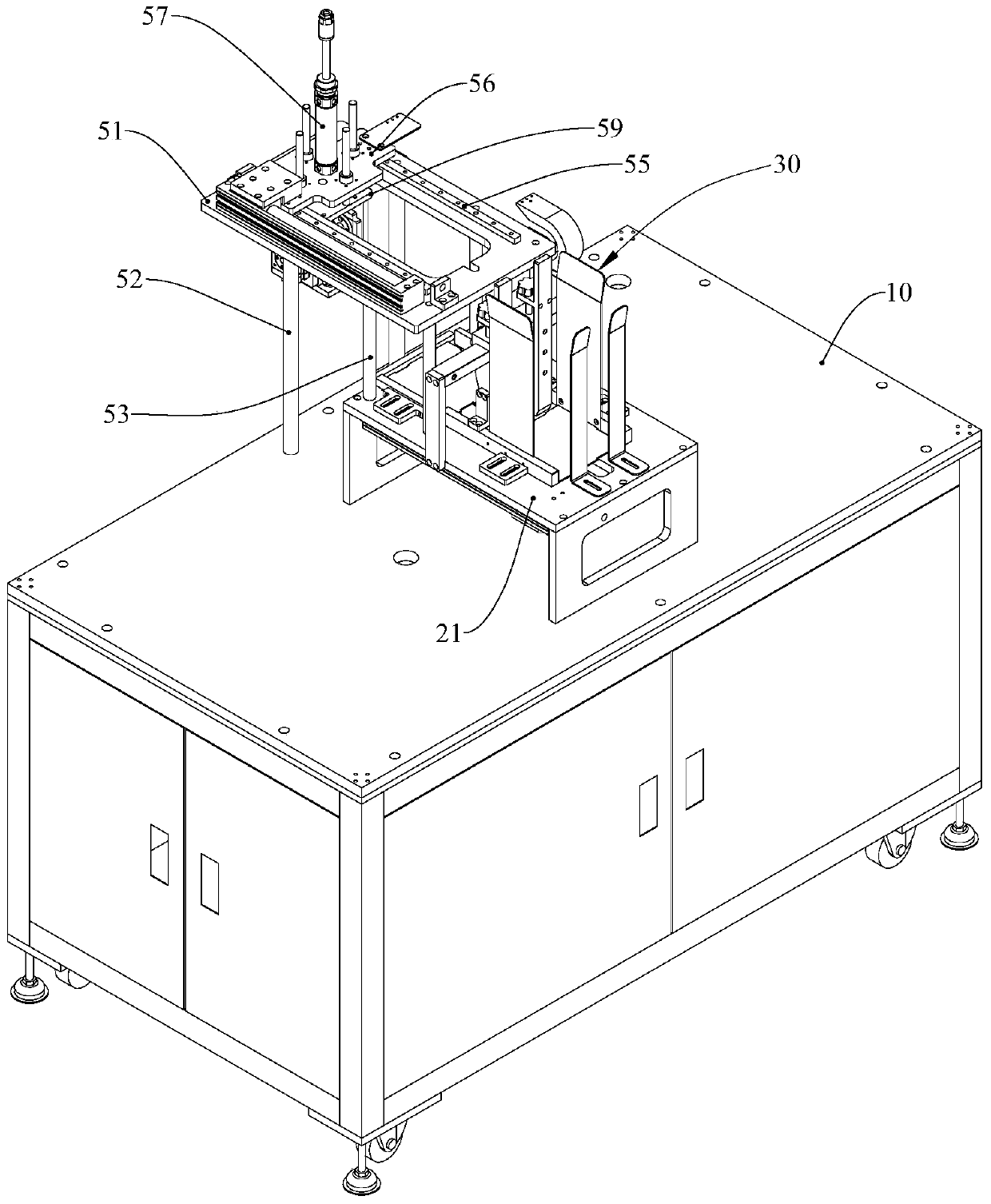

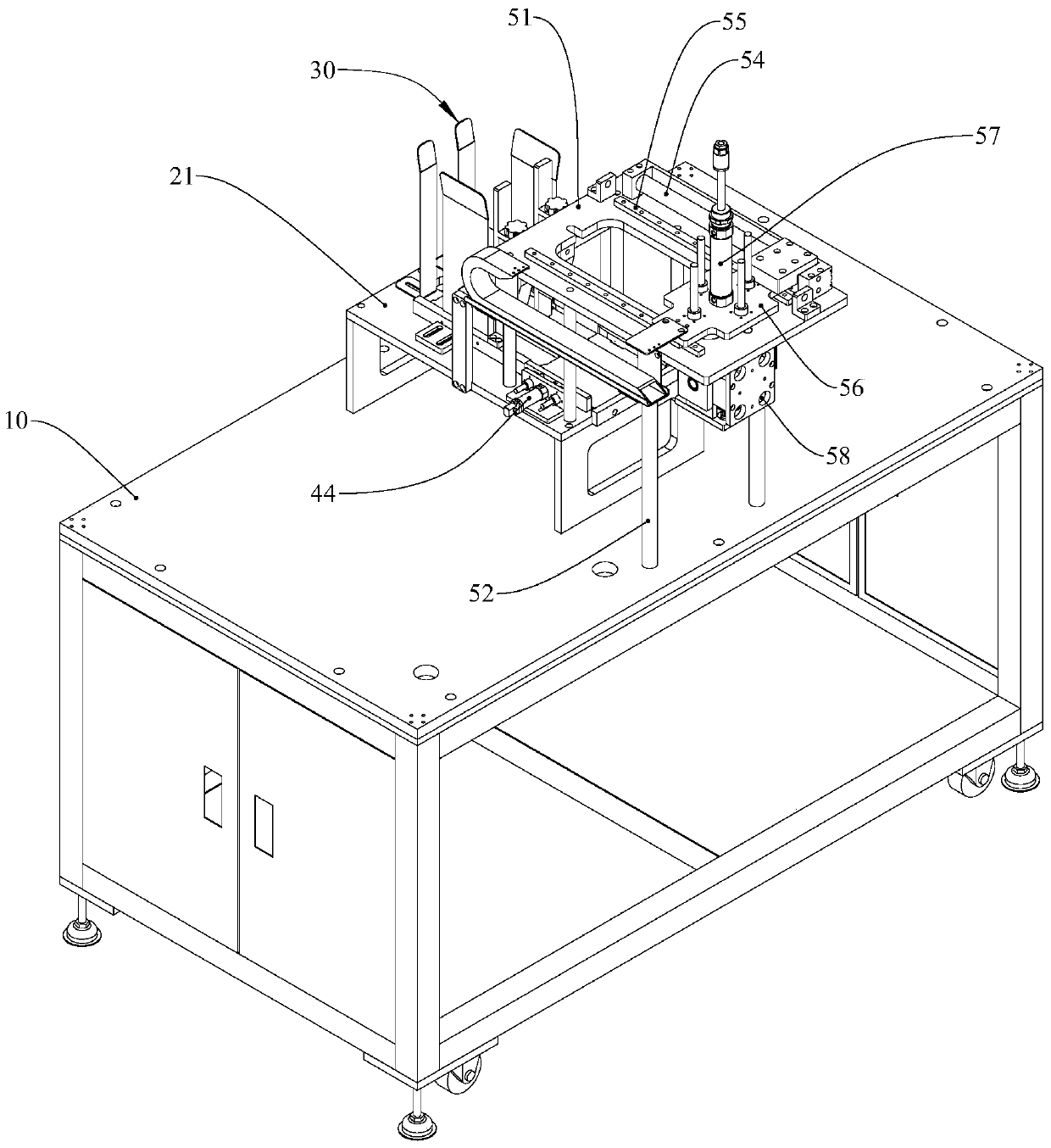

[0027] The concrete structure of the embodiment of the present invention is as Figure 1 to Figure 7 shown.

[0028] Such as figure 1 with figure 2 As shown, the bottom gray board feeding device for packaging box processing in this embodiment includes a machine table 10, a pushing mechanism for pushing out gray boards from stacked gray boards, and a gray board for pushing out the pushing mechanism. The board is sent to the loading mechanism on the cavity. Pushing mechanism and charging mechanism are all fixed on the machine platform 10.

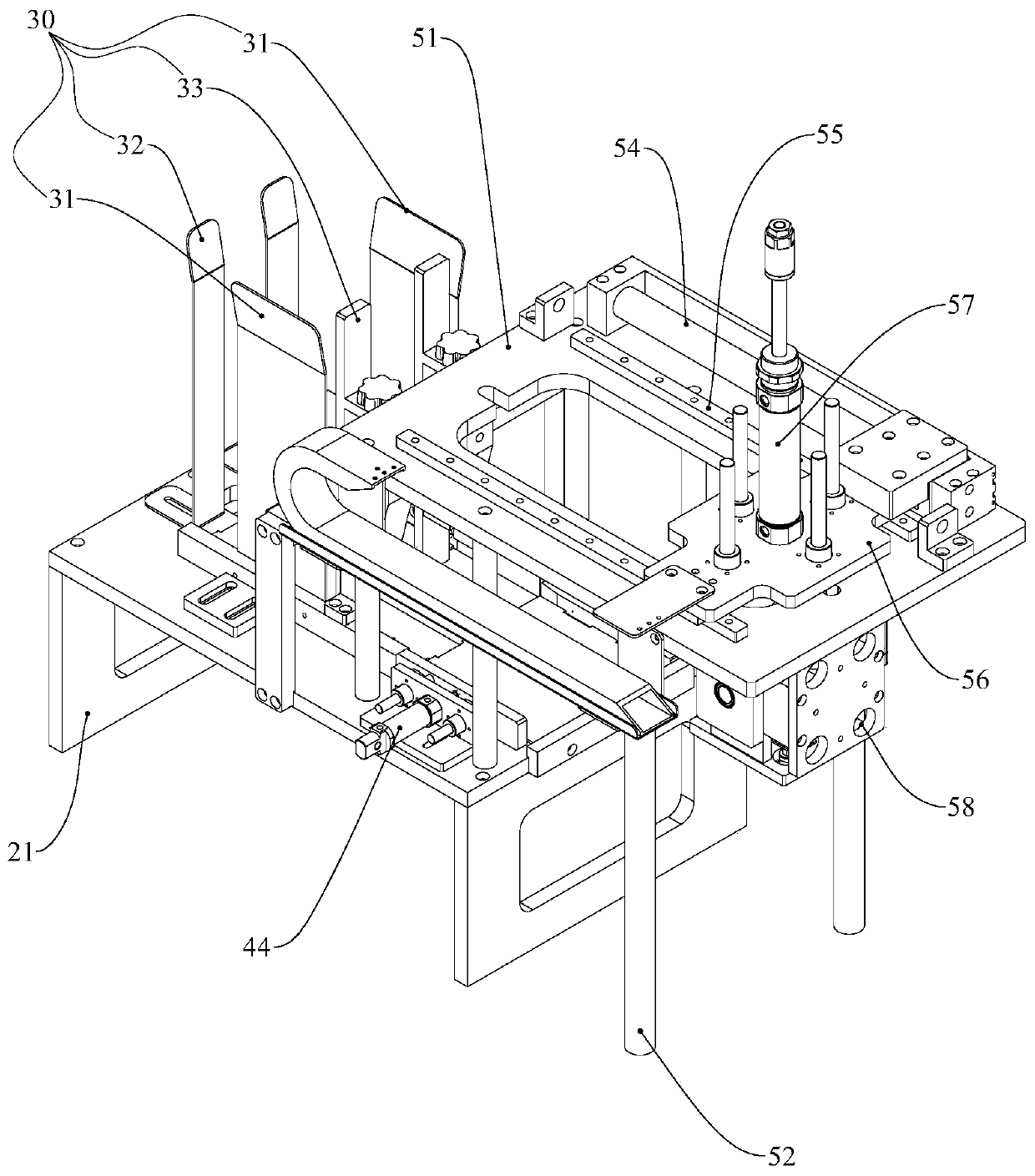

[0029] Such as Figure 3 to Figure 5 As shown, the pushing mechanism includes a mounting frame 21 fixed on the machine platform 10, a baffle assembly 30 for surrounding stacked gray boards and a pushing block 26 ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com