Environment-friendly jean fabric

A denim fabric, environmentally friendly technology, applied in the field of textile and apparel fabrics, can solve the problems of poor air permeability and lack of good luster, and achieve the effect of soft hand feeling, beautiful luster and anti-static wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

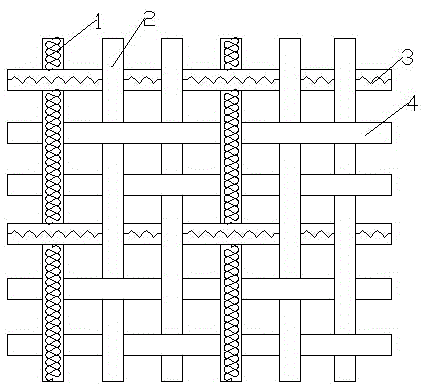

[0009] Such as figure 1 As shown, the environment-friendly denim fabric includes warp threads and weft threads. The warp threads include a first warp thread 1 and a second warp thread 2. One first warp thread 1 and two second warp threads 2 are arranged circularly in sequence, and the weft threads include the first warp thread. A weft thread 3, a second weft thread 4; the first weft thread 3 and the two second weft threads 4 are arranged circularly in turn; the first warp thread 1 is polyester-bamboo composite cotton fiber, and the composite cotton fiber is Cotton fiber is used as the core yarn, and polyester fiber and bamboo fiber are spirally twisted on the cotton fiber; the second warp thread 2 is wood tencel; the first weft thread 3 is bamboo hemp composite cotton fiber, and the The bamboo-linen composite cotton fiber is cotton fiber as the core yarn, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com