Pipe fitting clamping connector

A connecting piece and clamping technology, which is applied in the direction of pipes/pipe joints/fittings, valve devices, passing components, etc., can solve the problems that the pipe fittings cannot be used in a large area, the control of the flow meter is not accurate enough, and the working efficiency of the pipe fittings is affected. To achieve the effect of expanding the scope of use, optimizing the effect of use, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

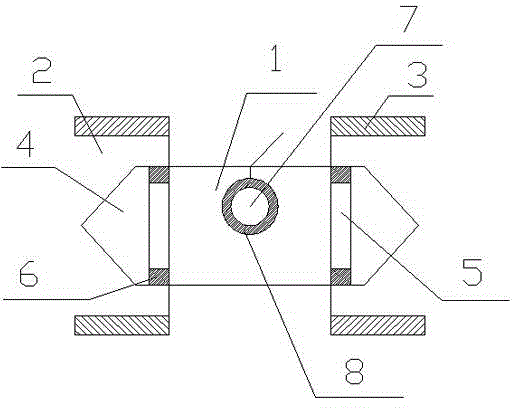

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] A clamping connector for pipe fittings, comprising an intermediate pipe 1 and a connecting pipe 2, the connecting pipe 2 is provided on both sides of the intermediate pipe 1, the connecting pipe 2 is a stainless steel connecting pipe, the connecting pipe 2 is provided with a rubber coating layer 3, and the rubber coating The thickness of the layer 3 is 5cm, the front part of the connecting pipe 2 is a pointed connector 4, the pointed connector 4 is a polyethylene mesh connector, and a concave shape is provided between the pointed connector 4 and the connecting pipe 2. Grille 5, the thickness of the concave grid 5 is 5cm, the concave groove of the concave grid 5 is filled with polyurethane 6, the intermediate pipe 1 is cylindrical, and the intermediate pipe 1 is provided with a water blocking member 7, the water blocking member 7 is The shape of a ball, the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com