Complicated stable sound field sound pressure testing device

A pressure testing and stable technology, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as troublesome debugging and installation, inability to complete on-site, and no detailed description, etc., to achieve convenient debugging, reliable test data, The effect of reducing human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

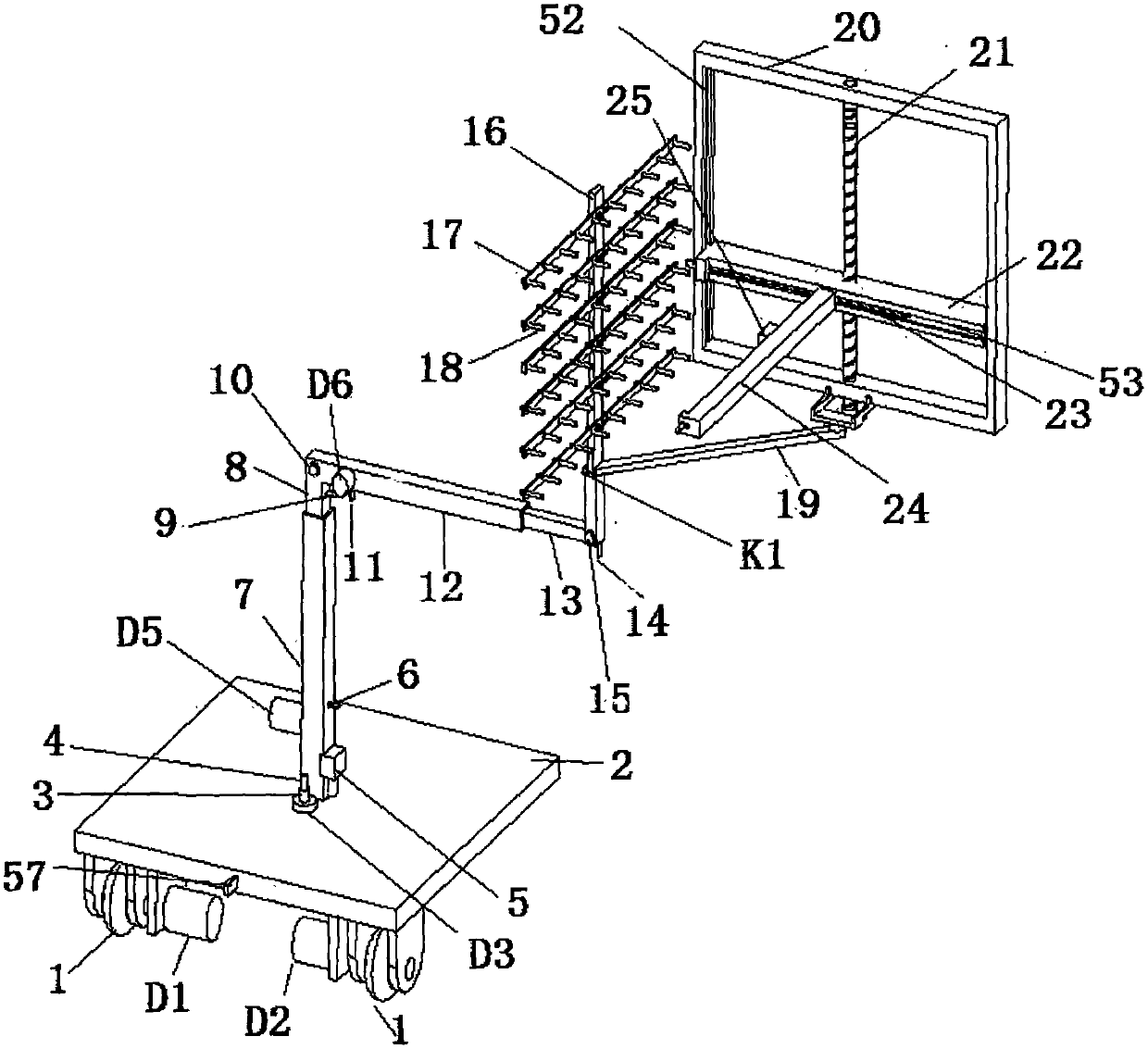

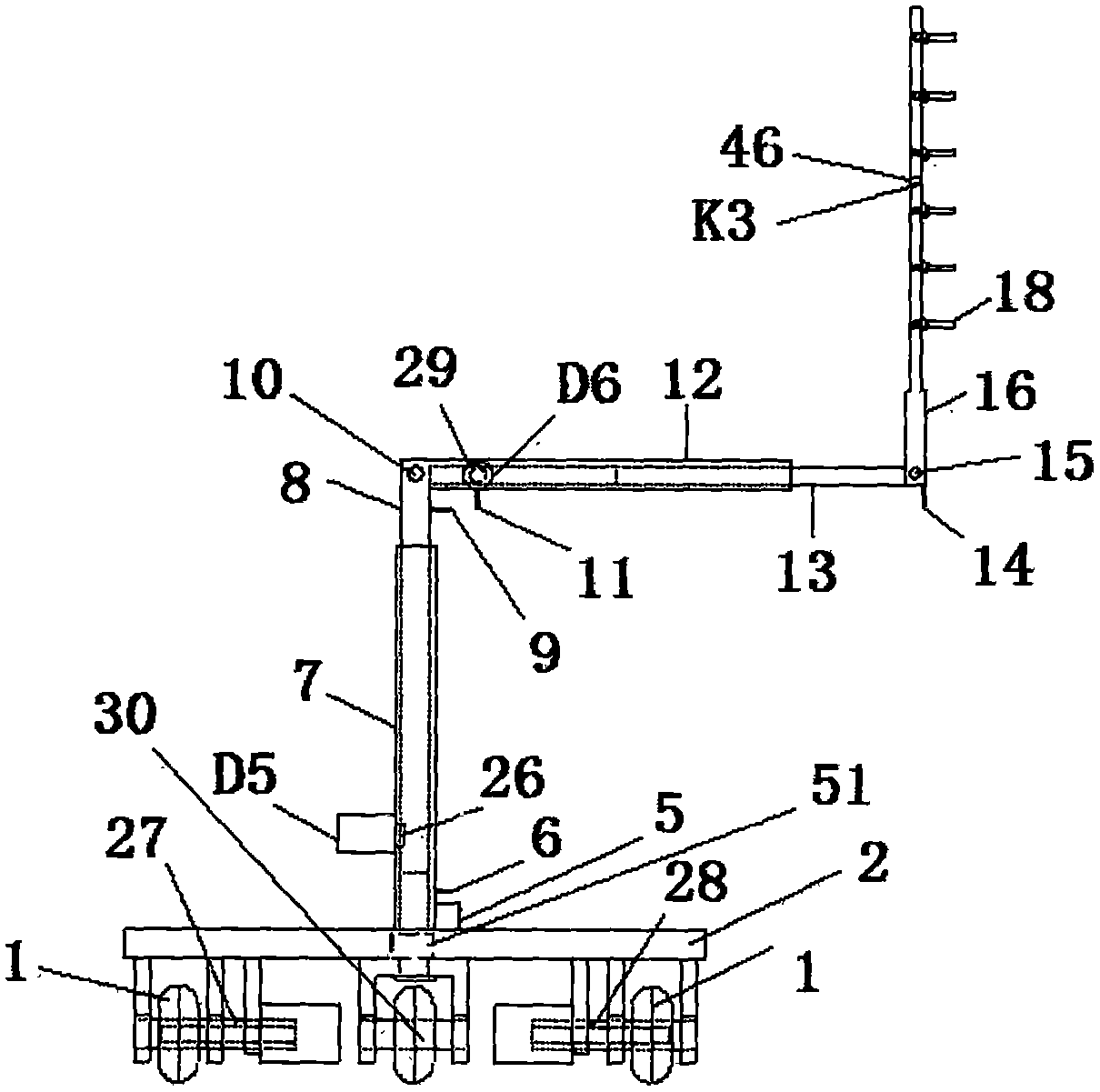

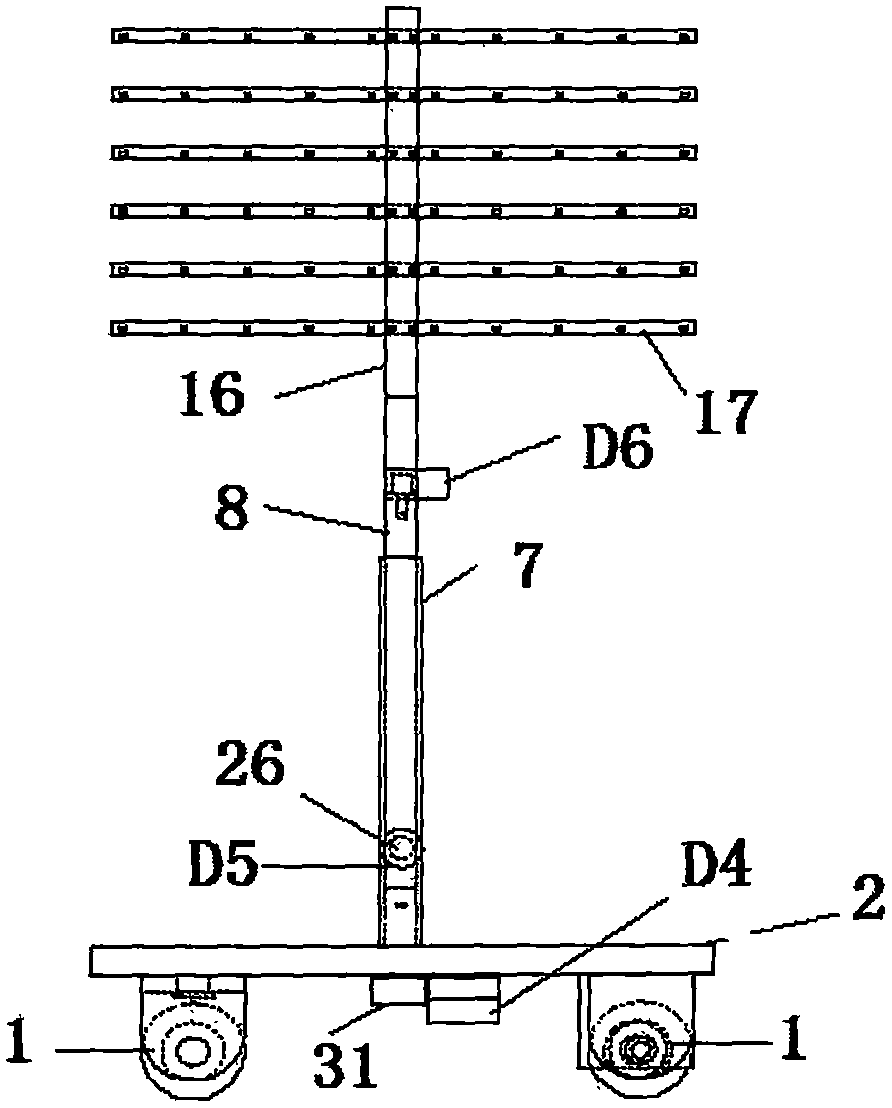

[0031] Such as Figure 1 to Figure 10 As shown, the present invention is a complex and stable sound field sound pressure testing device, which includes a driving mechanism I for the movement of the whole device, an acoustic probe array lifting and rotating driving mechanism II, an acoustic probe array telescopic driving mechanism III, an acoustic probe array IV, an acoustic Probe array test channel calibration drive mechanism V, sound source reference position measurement column VI, point sound source standard sound wave generator VII. The driving mechanism 1 of described whole device motion comprises base 2, base 2 is provided with driving wheel 1 and universal wheel 30, is provided with electric control box 5 on base 2, and electric control box 5 is used for placing control circuit board, and base 2. The center is connected with the chute I7 of the acoustic probe array lifting and rotating drive mechanism II through the bearing sleeve VIII51. The acoustic probe array lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com