Sampling method for dual-glass-assembly interior-packaging-material cross linking degree

A technology of double-glass components and internal packaging, which is applied in the direction of sampling, analyzing materials, and measuring devices. It can solve the problems of cross-linking agent extraction, large internal environment differences of double-glass components, and affect the accuracy of test results, etc., to achieve similarity The effect of high, reliable data results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

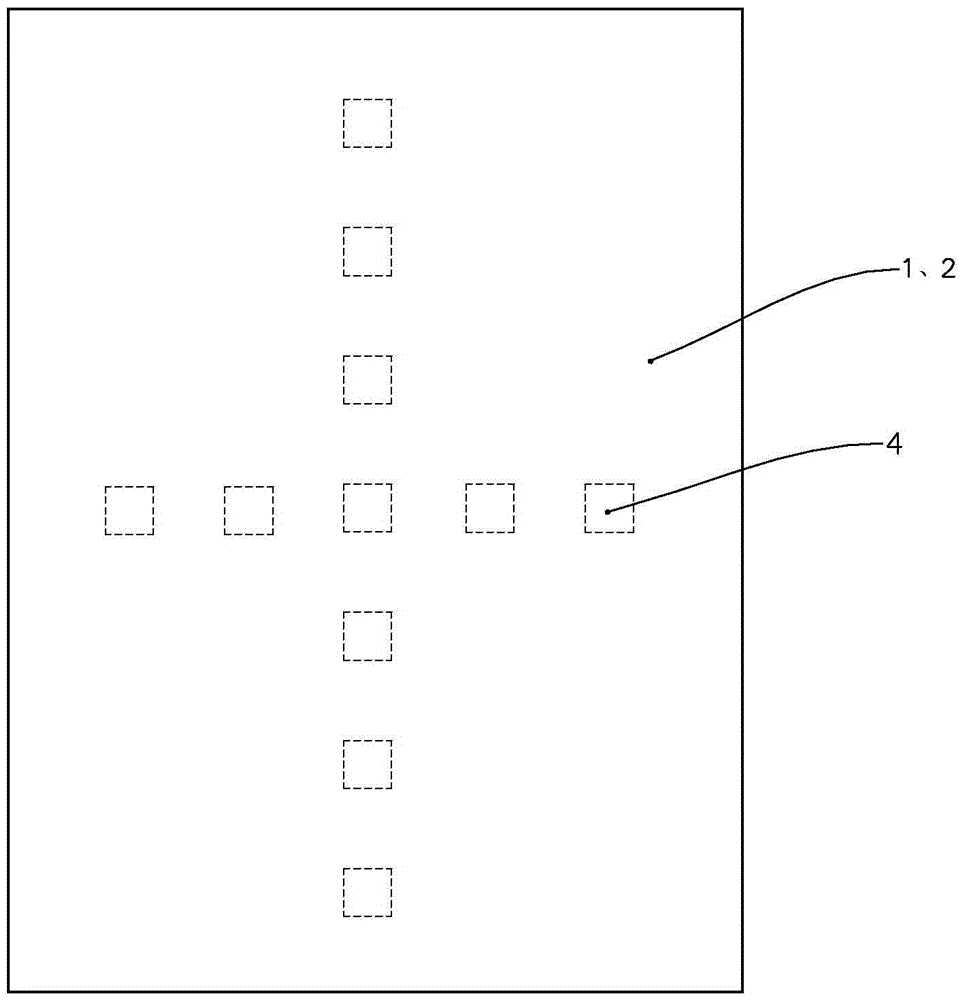

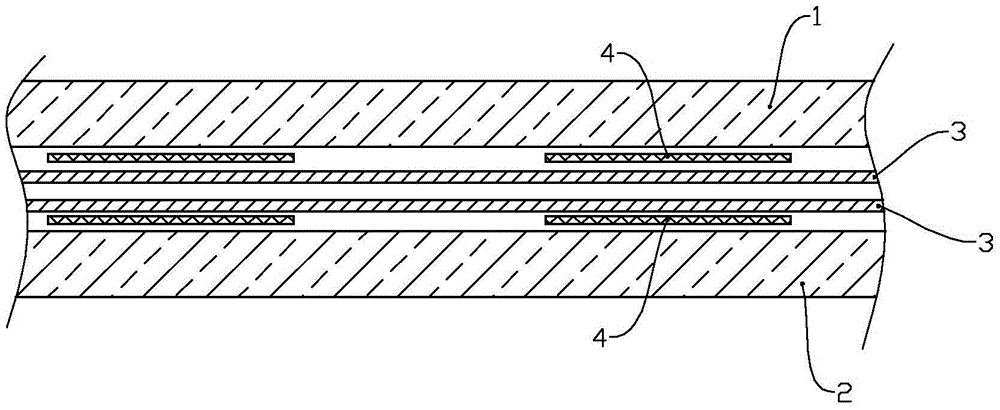

[0011] Prepare the front glass 1, rear glass 2, front and rear film encapsulation material 3 (POE film), and several small pieces of high-temperature cloth 4 for the double-glass module. 1658*992mm. Place the rear glass on a flat surface, and then arrange the first group of small pieces of high-temperature cloth on the rear glass (the arrangement position is as follows: figure 1 ), then cover two layers of front and rear film encapsulation materials, then arrange the second group of high-temperature cloth small pieces opposite to the first group of high-temperature cloth small pieces, and then cover the front glass to form figure 2 The cross-sectional layered structure shown. After the preliminary sample preparation is completed, the samples are sent to the laminator for lamination. Finally, the laminated sample was smashed with a hammer in the place where there was a high-temperature cloth, and the cross-linking degree sample sandwiched in the middle of the high-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com