A method for online monitoring of odor concentration

A concentration and odor technology, which is used in measurement devices, analysis of gas mixtures, standard gas analyzers, etc., can solve the problems of abnormally complex composition of odor pollutants, distortion of response spectrum of electronic nose method, and inapplicability of pattern recognition algorithms. Achieve accurate and reliable data results, simple and convenient maintenance, and equipment that is resistant to leather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

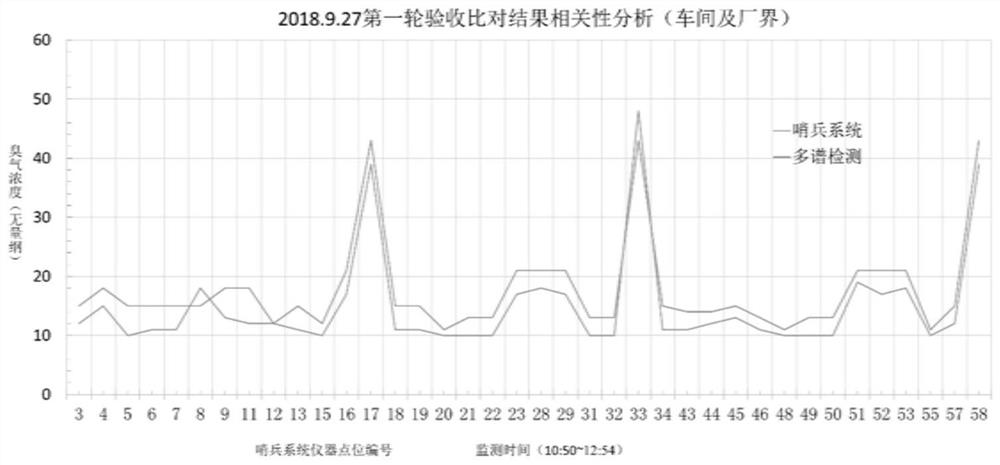

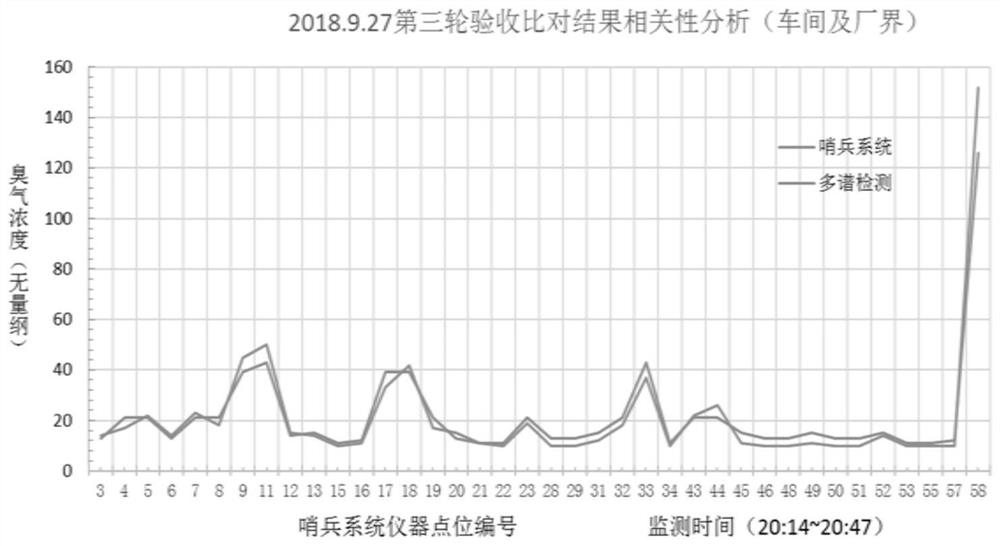

[0051] A total of 47 monitoring points were selected from several adjacent enterprises in a certain place. The online mass spectrometer monitored all the points once every 2 hours, continuously monitored 24 hours a day, and arranged artificial odor concentration monitoring at the same time. An effective odor monitoring model for mass spectrometry data, and the model predicts the odor concentration of the measured gas, which specifically includes the following steps:

[0052] (1) The online mass spectrometer does not have a pretreatment separation system such as a chromatographic column, and the measured gas directly enters the online mass spectrometer for online monitoring.

[0053] (2) Carry out continuous sampling of the measured gas under a certain working condition, use an online mass spectrometer to perform full-scan analysis on the measured gas, record the full-scan mass spectrum, and obtain each ion and its ion intensity; use three-point comparison simultaneously Manual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com