Modularization area power transformation integration distribution box

A technology of modularization and distribution box, applied in substation/switch layout details, electrical components, switchgear, etc., can solve the problems of not being able to better meet the reliability of power supply, affecting the normal use of functional intervals, and affecting other power circuits , to achieve good ventilation and heat dissipation functions, flexible configuration schemes, and complete protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] Specific implementation methods: the present application is not limited by the following examples, and the specific implementation manners can be determined according to the technical solutions of the application and actual conditions.

Embodiment

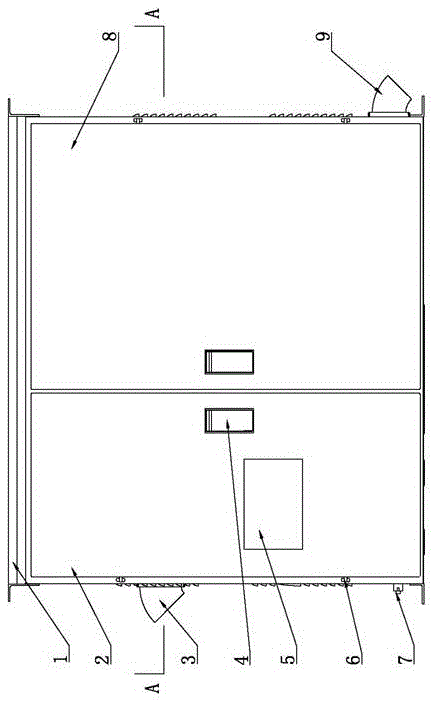

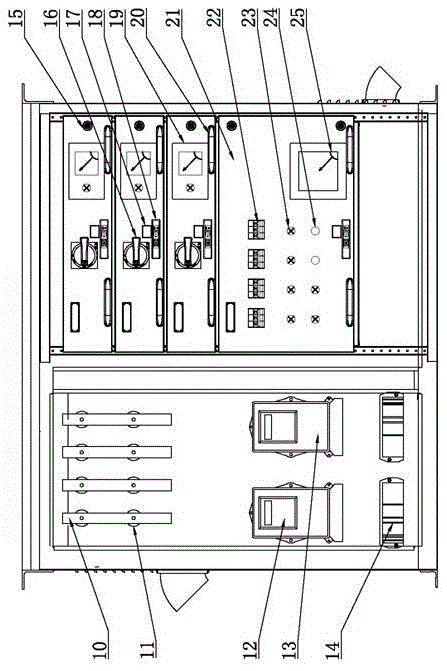

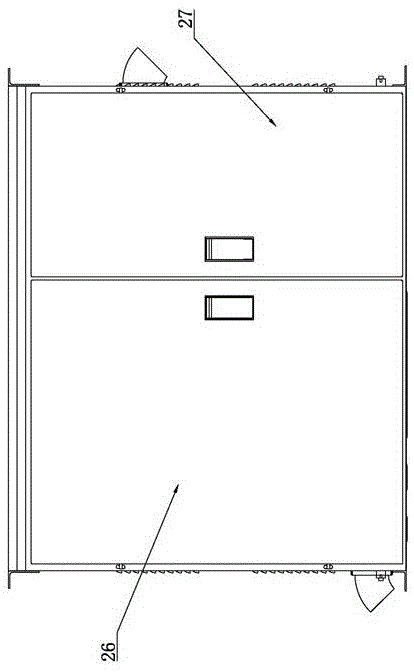

[0017] Example: such as Figure 1-5 As shown in the figure, the integrated power distribution box of the modular station area includes a metering unit room 2, a main incoming line unit room 27, a bus bar insulation unit room 32, an outgoing line drawer unit room 15, and a reactive power compensation drawer unit room 21.

[0018] The main incoming line knife melting switch 34 is installed in the main incoming line unit room 27, and the main bus bar 39 of the main incoming line knife melting switch 34 is connected to the outgoing line drawer unit room 15 and the reactive power compensation drawer unit room 21. The primary static contact 29 terminals on the line side are fixed by the bus bar clamp and insulated and sealed by the bus bar insulation unit chamber 32 sealing plate. Make its entire system circuit connected as one;

[0019] The lightning protection module is installed in the main incoming line unit room 27, with 4-level micro-break 35 and lightning protection module 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com