Mobile recoverable oil sludge oil sand processing unit

A treatment device and oil recovery technology, applied in the direction of grease/oily substance/suspton removal device, dehydration/drying/concentrated sludge treatment, separation method, etc. Waste of precious energy and other issues, to achieve the effect of reducing total investment and operating costs, small footprint, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

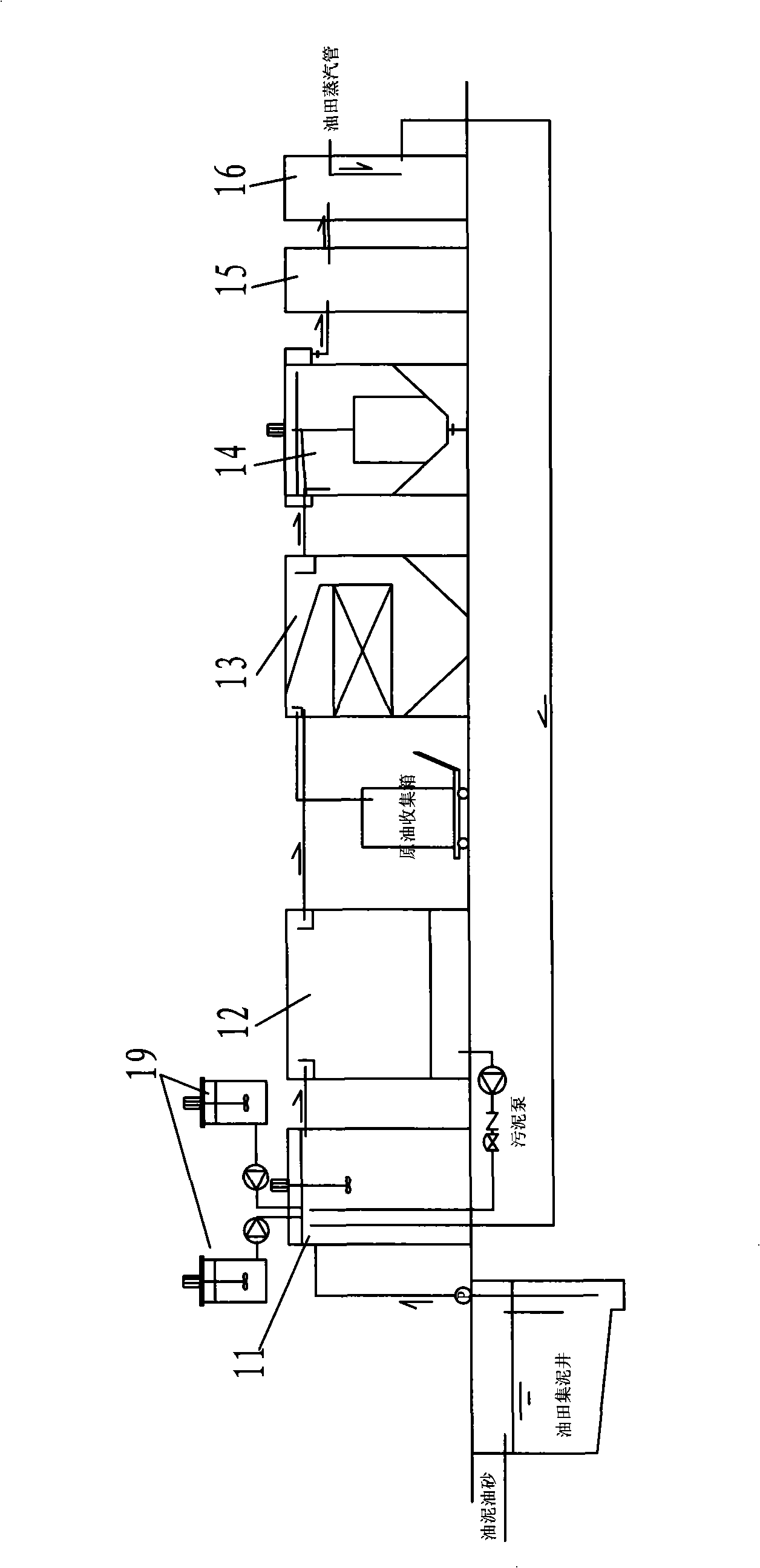

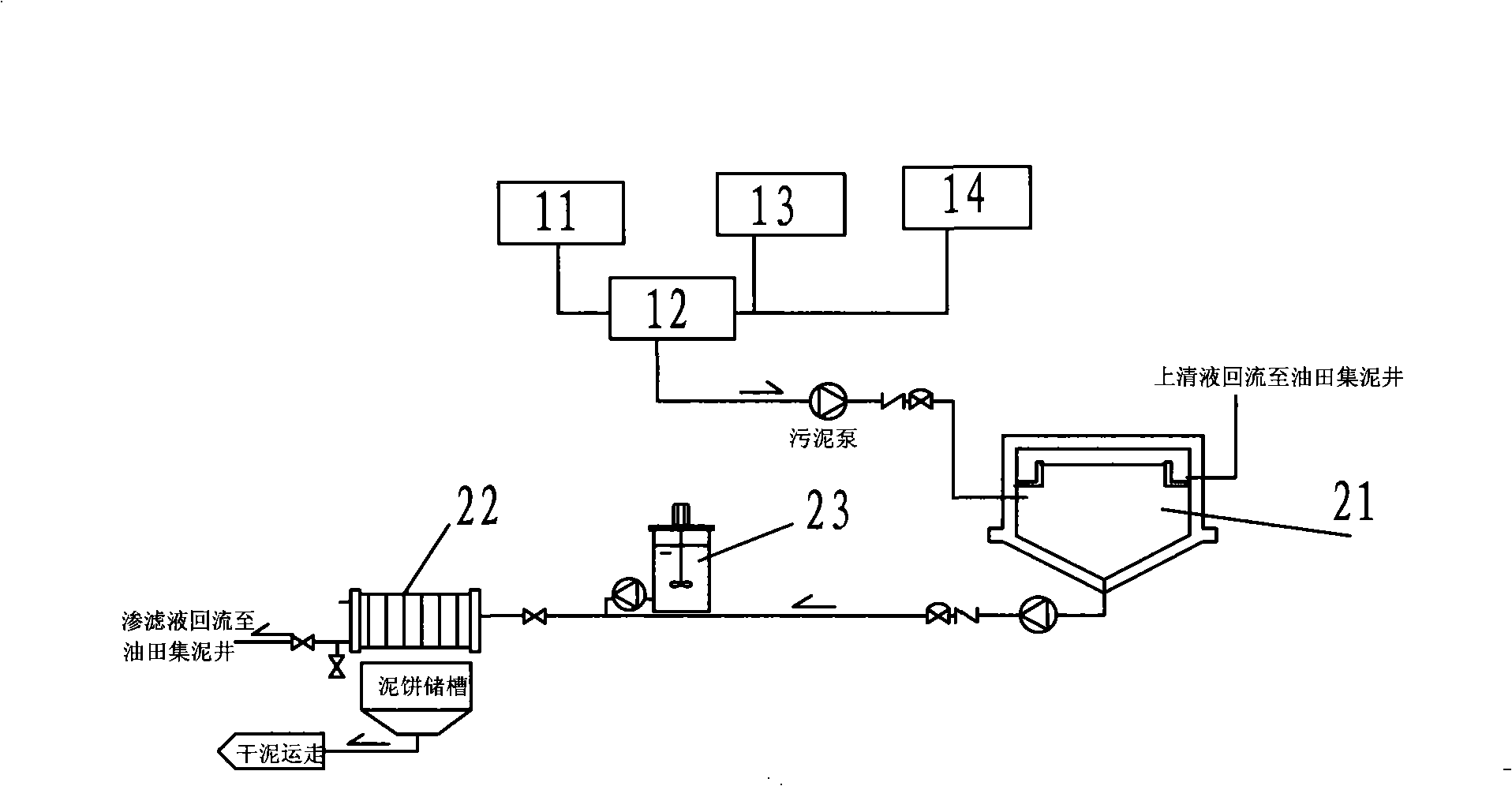

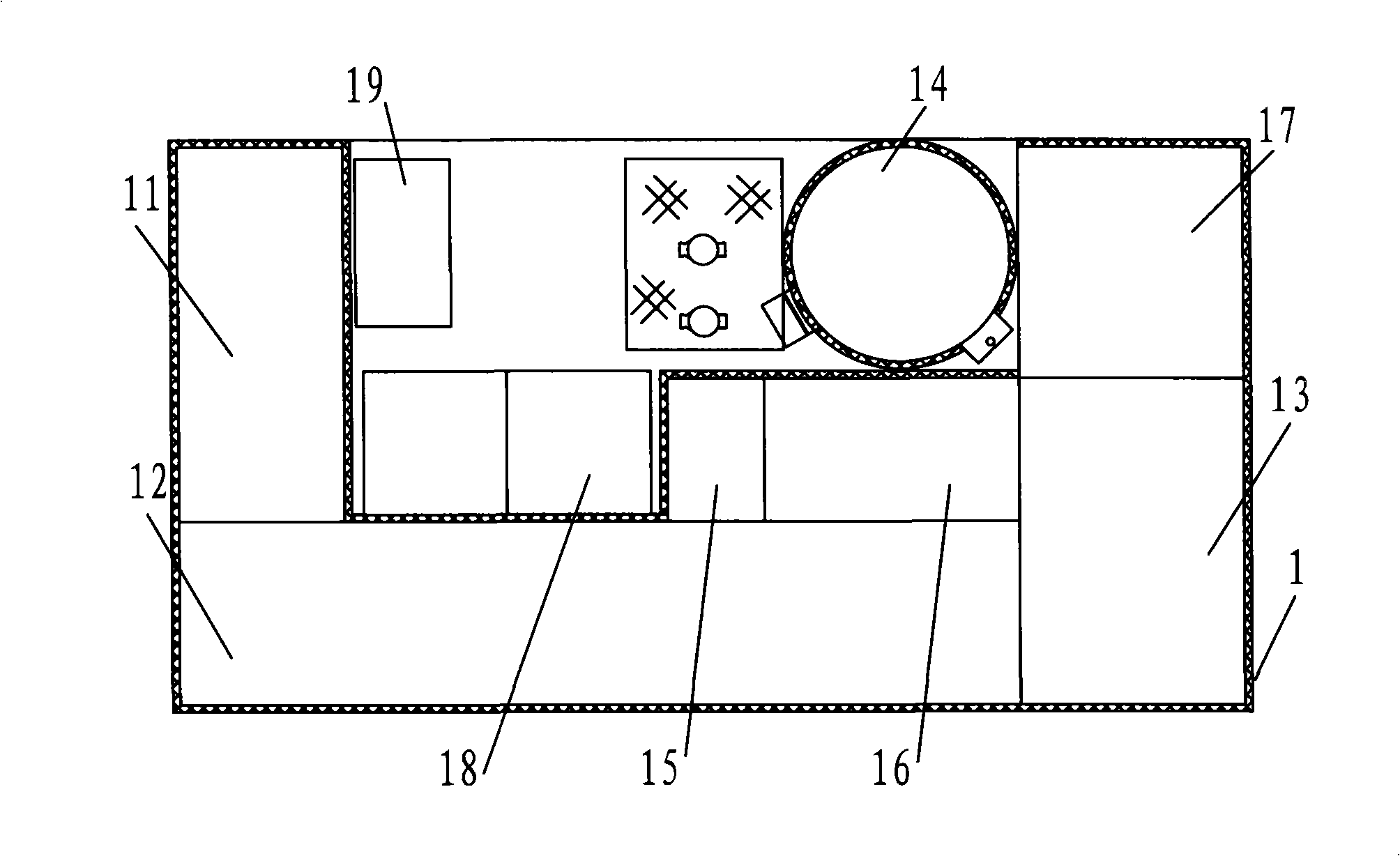

[0031] The present invention will be further explained below in conjunction with the accompanying drawings.

[0032] Such as image 3 , 4 As shown, the mobile recyclable oil sludge and oil sand treatment device of the present invention includes a first box body 1 and a second box body 2, and the first box body 1 and the second box body 2 are all provided with lifting rings for loading. The bottom of each box is welded by channel steel and steel plate.

[0033]The first box body 1 is provided with a reaction tank 11 , a settling tank 12 , a grease trap 13 , an air flotation device 14 , a reclaimed water tank 15 , a hot water tank 16 , a replenishing water tank 17 , a dosing device 18 and a PLC control device 19 . The oil sludge and oil sand in the mud collection well are transported into the reaction tank 11 through a sludge pump installed in the first box 1, and a tank wall of the reaction tank 11 with a stirring device inside is shared with a section of the tank wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com