Independent shoe last model for shoemaking and high-heeled shoes

A technology for high-heeled shoes and shoes, which is applied to shoe lasts, footwear, and soles, etc. It can solve problems such as foot injuries, foot grinding, and heel drop, and achieve the effects of stable wearing, correcting hunched posture problems, and reducing the load on the soles of the feet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

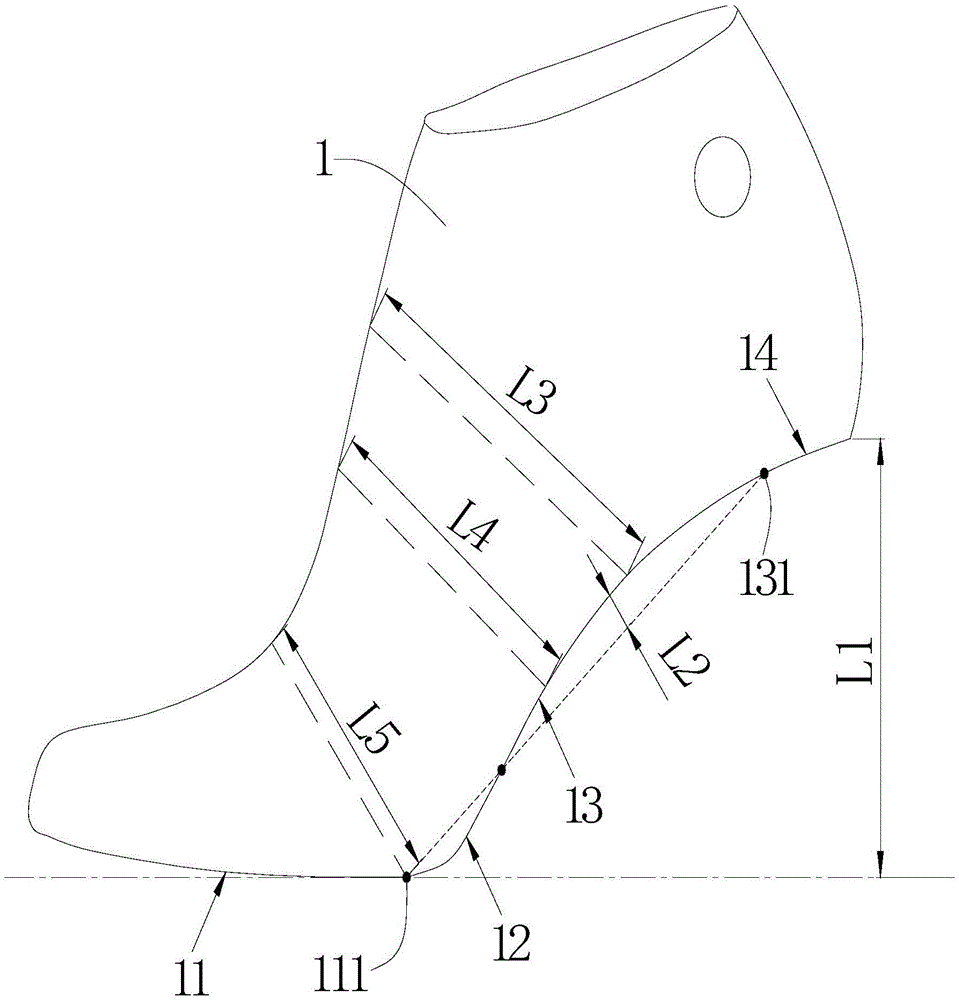

[0023] Such as figure 1 As shown, an independent last type for shoemaking, including an integrally formed last body 1 of the bionic human foot, the bottom surface of the last body 1 is formed with a forefoot curved surface 11, a waist fossa curved surface 13 and a heel curved surface 14, so The end of the forefoot curved surface 11 is the landing point 111, and the forefoot curved surface 11 is in a convex arc shape protruding toward the outside of the last from the end to the front end, and the front end of the forefoot curved surface 11 is opposite to the landing point 111 Upward 12mm; the end of the forefoot curved surface 11 is connected to the front end of the waist curved surface 13 through the connecting curved surface 12, the connecting curved surface 12 is in the shape of a convex arc protruding toward the outside of the last, and the waist curved surface 13 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com