Jaw direction adjustment mechanism of endoscope cutting stapler

A direction adjustment and stapler technology, which is applied in the field of medical devices, can solve problems such as flexibility constraints, large operating force, and inability to effectively prevent jaws from swinging back or blocking, and achieve the effect of easy and labor-saving adjustment mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described below in conjunction with accompanying drawing.

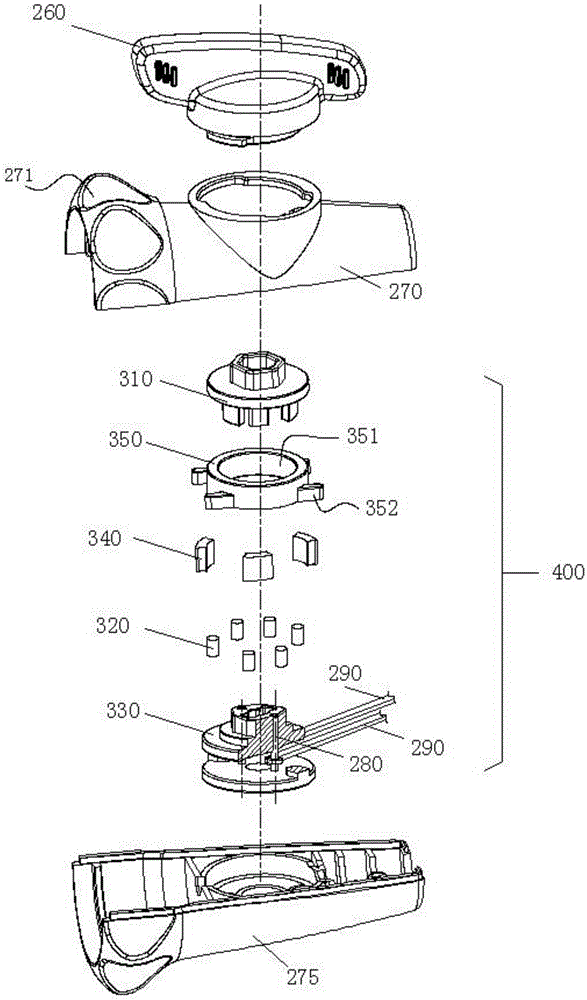

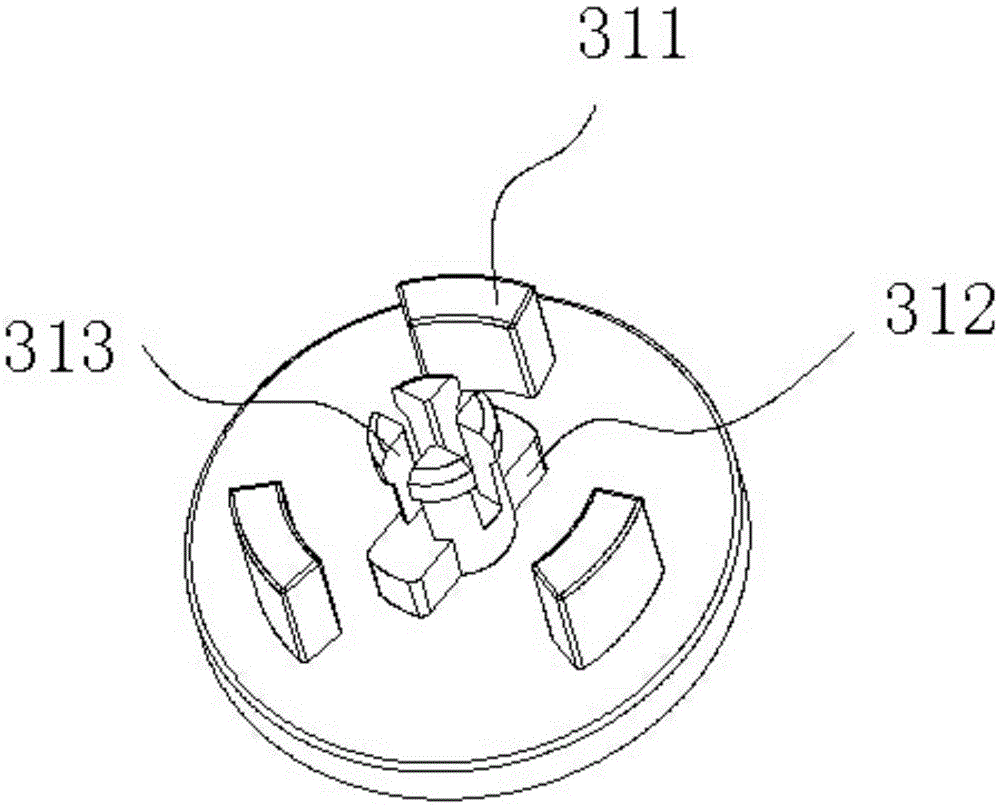

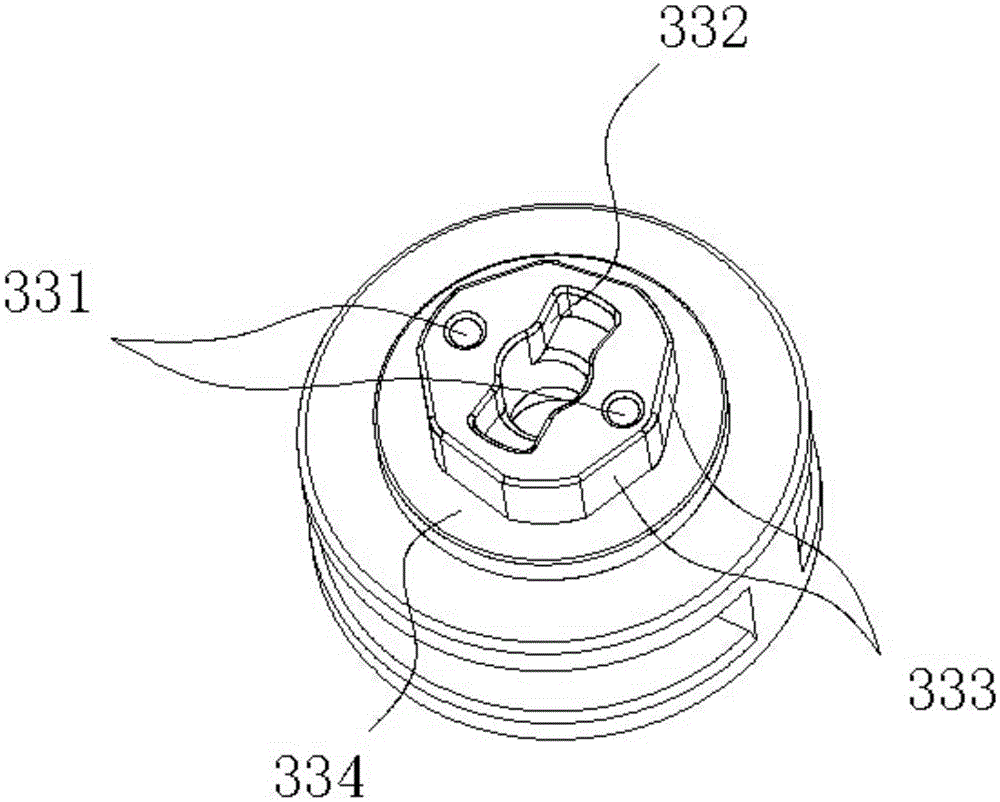

[0023] as attached Figure 1-7As shown, the jaw direction adjustment mechanism of a laparoscopic cutting stapler according to the present invention includes a joint knob 260, a rotating head and a two-way adjusting assembly 400. The two-way adjusting assembly 400 is rotatably arranged in the rotating head, and the rotating head Divided into an upper swivel head 270 and a lower swivel head 275; the two-way adjustment assembly 400 includes a main turntable 310, an outer ring 350, three elastic bodies 340, six rollers 320, an inner star wheel 330, and two pin shafts 280 and two joint push rods 290; the joint knob 260 is rotatably arranged on the upper rotary head 270, the top surface of the main turntable 310 cooperates with the joint knob 260 through a hexagonal boss structure, and the bottom surface is provided with a transmission pin 312, a card Pin 313 and three circularly distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com