Back-blow dedusting system

A soot and dust removal technology, which is applied in the direction of dispersed particle filtration, membrane filter, gas treatment, etc., can solve the problems of complex structure, high cost and waste of air flow in the soot blowing system, and achieve good dust removal effect, high air flow, The effect of simplifying the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following, the technical solution of a back-blowing dust-cleaning system involved in the present invention will be further described in detail with reference to the drawings and embodiments.

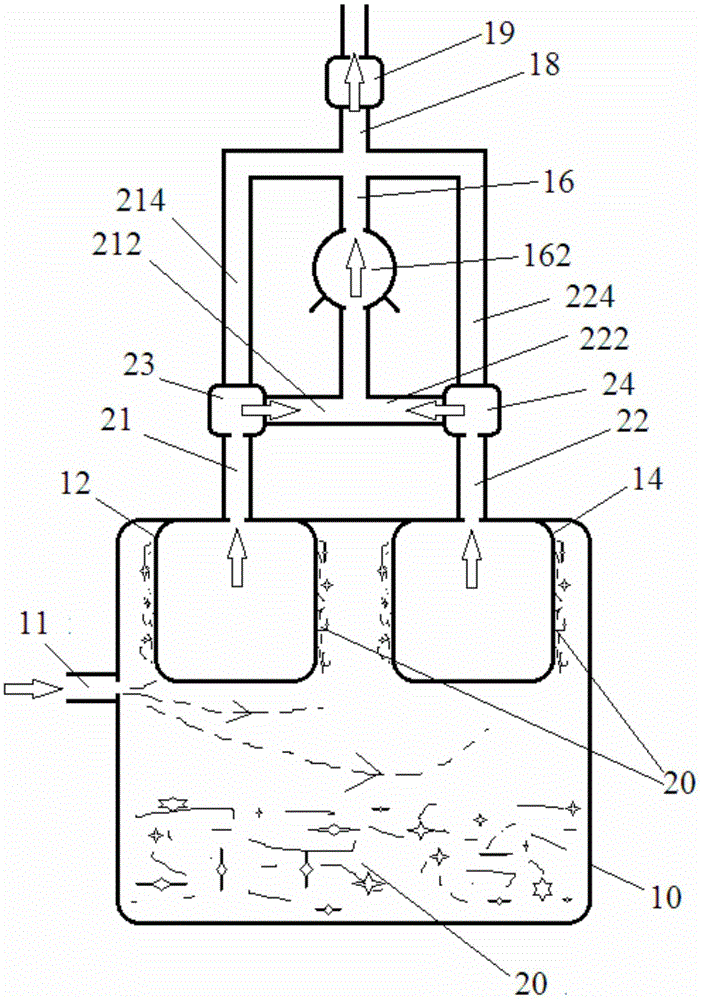

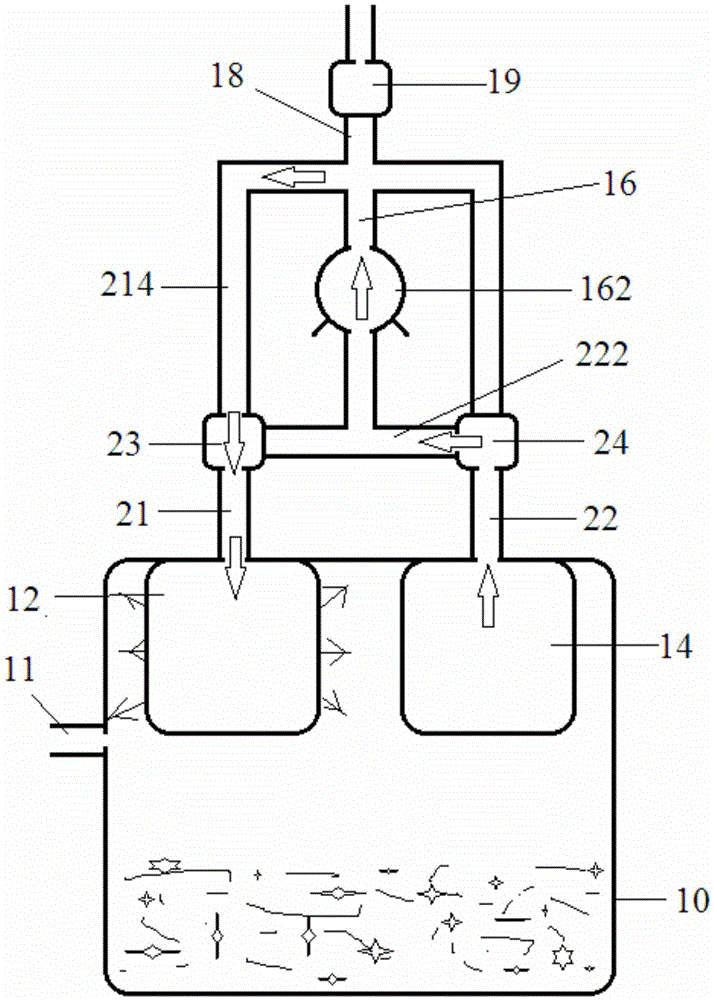

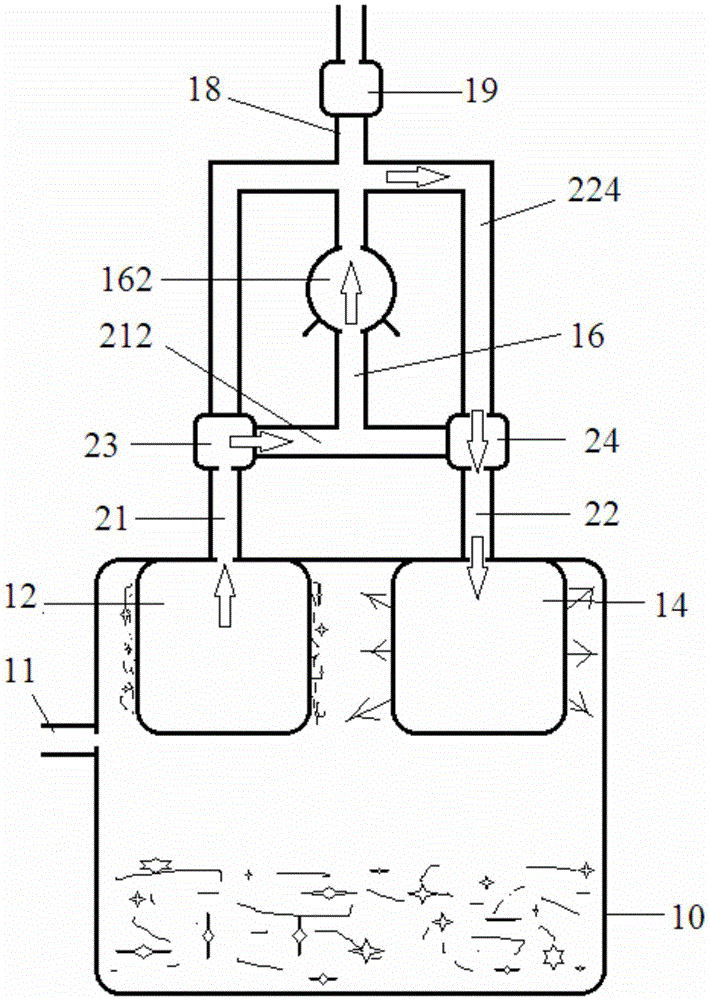

[0036] see figure 1 As shown, an embodiment of the present invention provides a reverse blowing dust cleaning system, which includes a first channel 21 , a second channel 22 , a fan channel 16 , and an exhaust channel 18 . One end of the first channel 21 and the second channel 22 are respectively used to connect the first filter device 12 and the second filter device 14 , and the fan channel 16 is provided with a fan 162 .

[0037] Wherein the first channel 21 and the second channel 22 are further provided with a first valve 23 and a second valve 24 respectively. And the first passage 21 leads out from the first valve 23 to the first branch 212 and the second branch 214, and the second passage 22 leads out from the second valve 24 to the third branch 222 and the second br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com