Patents

Literature

32results about How to "Realize cleaning operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

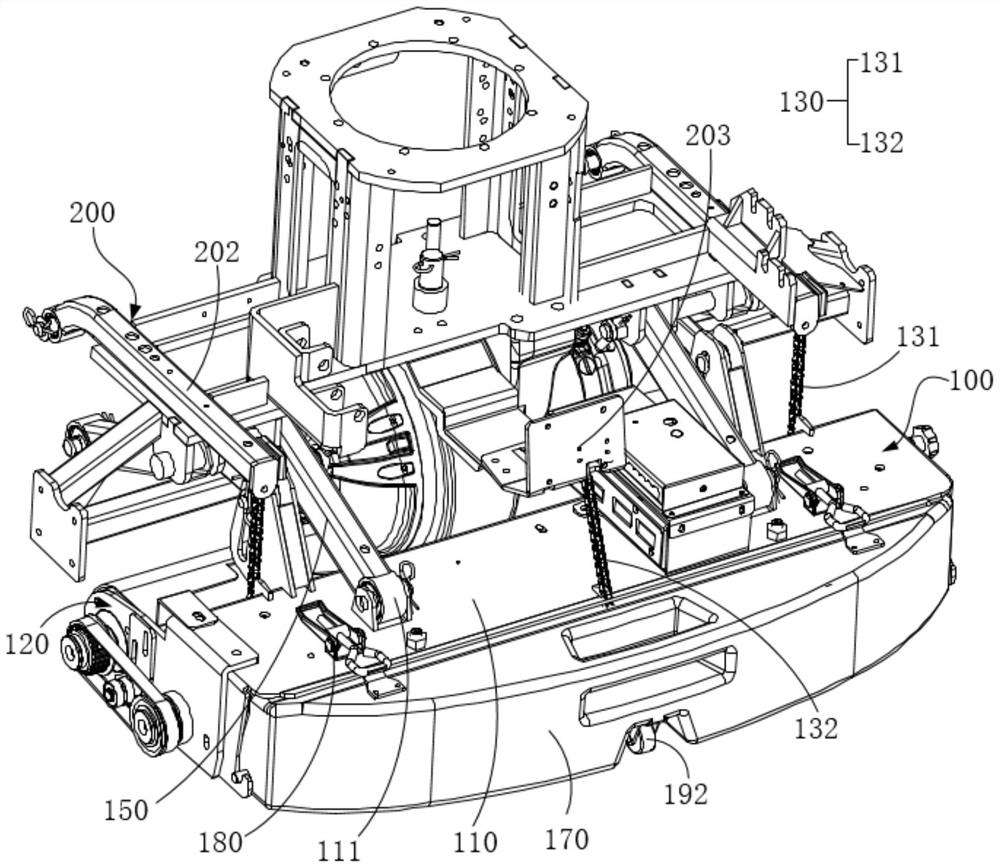

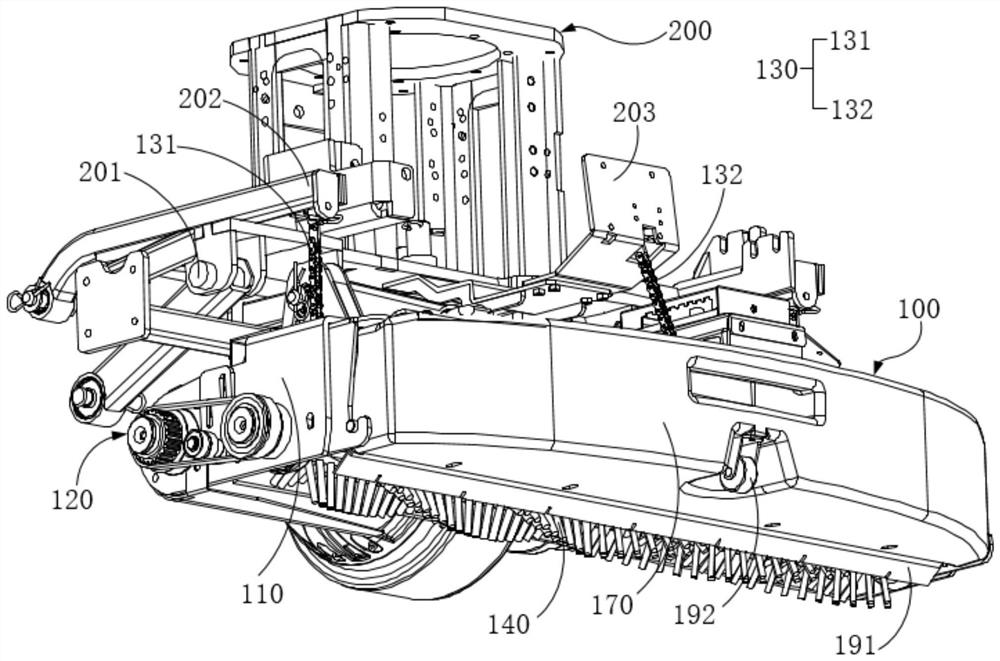

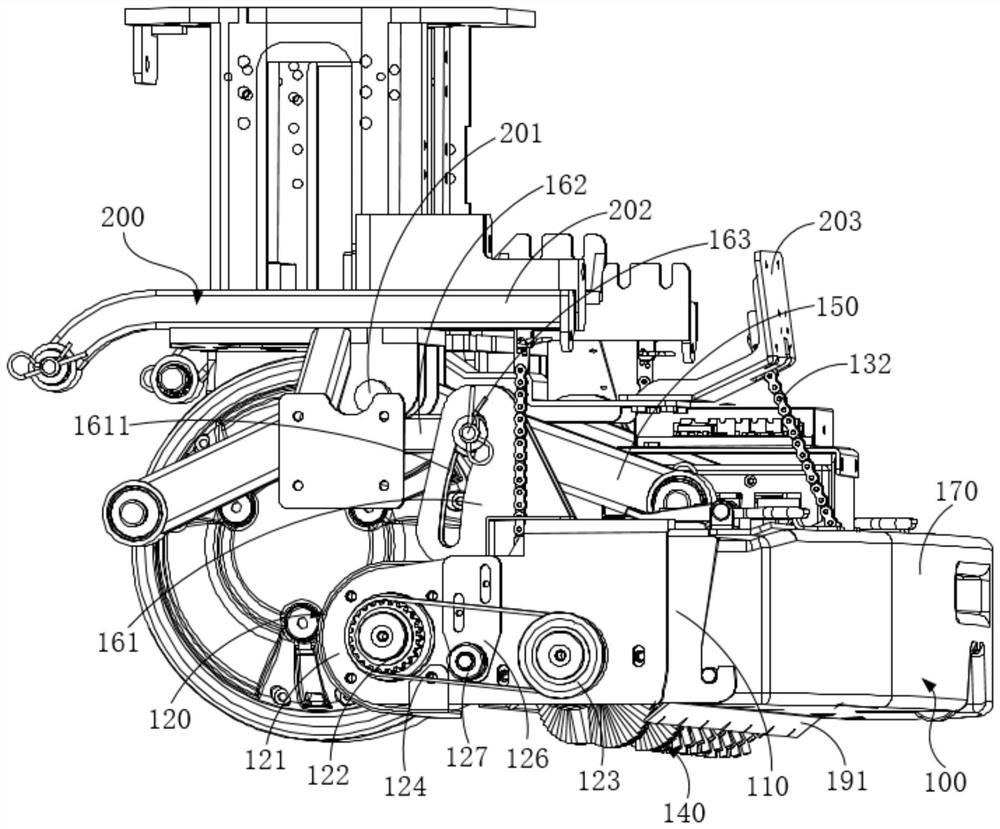

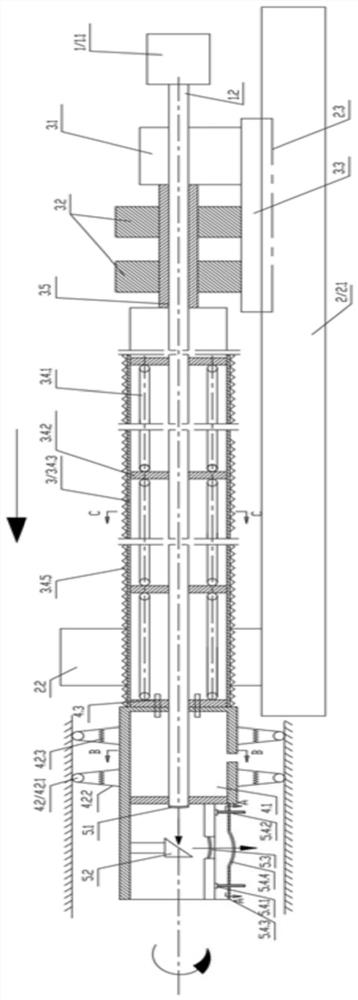

Cleaning rolling brush structure and cleaning robot

InactiveCN113080780ARealize cleaning operationHas a lifting effectCarpet cleanersFloor cleanersControl engineeringBrush

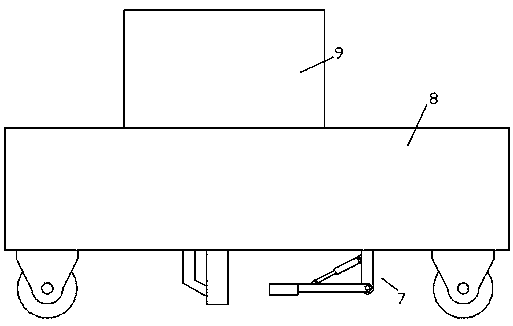

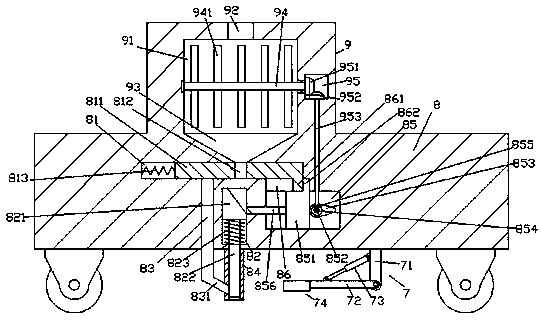

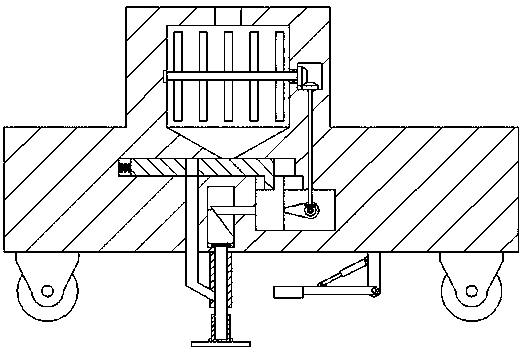

The invention relates to a cleaning rolling brush structure and a cleaning robot, and relates to the technical field of cleaning. The cleaning rolling brush structure comprises a rolling brush, a mounting frame, a driving mechanism, a lifting mechanism and a plurality of lifting chains, wherein the mounting frame is provided with a mounting cavity, and the rolling brush is accommodated in the mounting cavity and rotationally connected to the mounting frame; the driving mechanism is mounted on the mounting frame, the power output end of the driving mechanism is in transmission connection with the rolling brush, and the driving mechanism is used for driving the rolling brush to rotate around the axis of the rolling brush; the lifting mechanism is mounted on a cleaning rack, the power output end of the lifting mechanism is connected with the mounting frame, and the lifting mechanism is used for driving the mounting frame to ascend and descend in the vertical direction; the plurality of lifting chains are arranged on the mounting frame at intervals; and one end of each lifting chain is connected to the mounting frame, and the other end of each lifting chain is connected to the cleaning rack. According to the cleaning rolling brush structure, through cooperation of the lifting mechanism and the plurality of lifting chains, the mounting frame drives the rolling brush to move to the height position, and the connection reliability of the rolling brush is improved.

Owner:苏州高之仙自动化科技有限公司

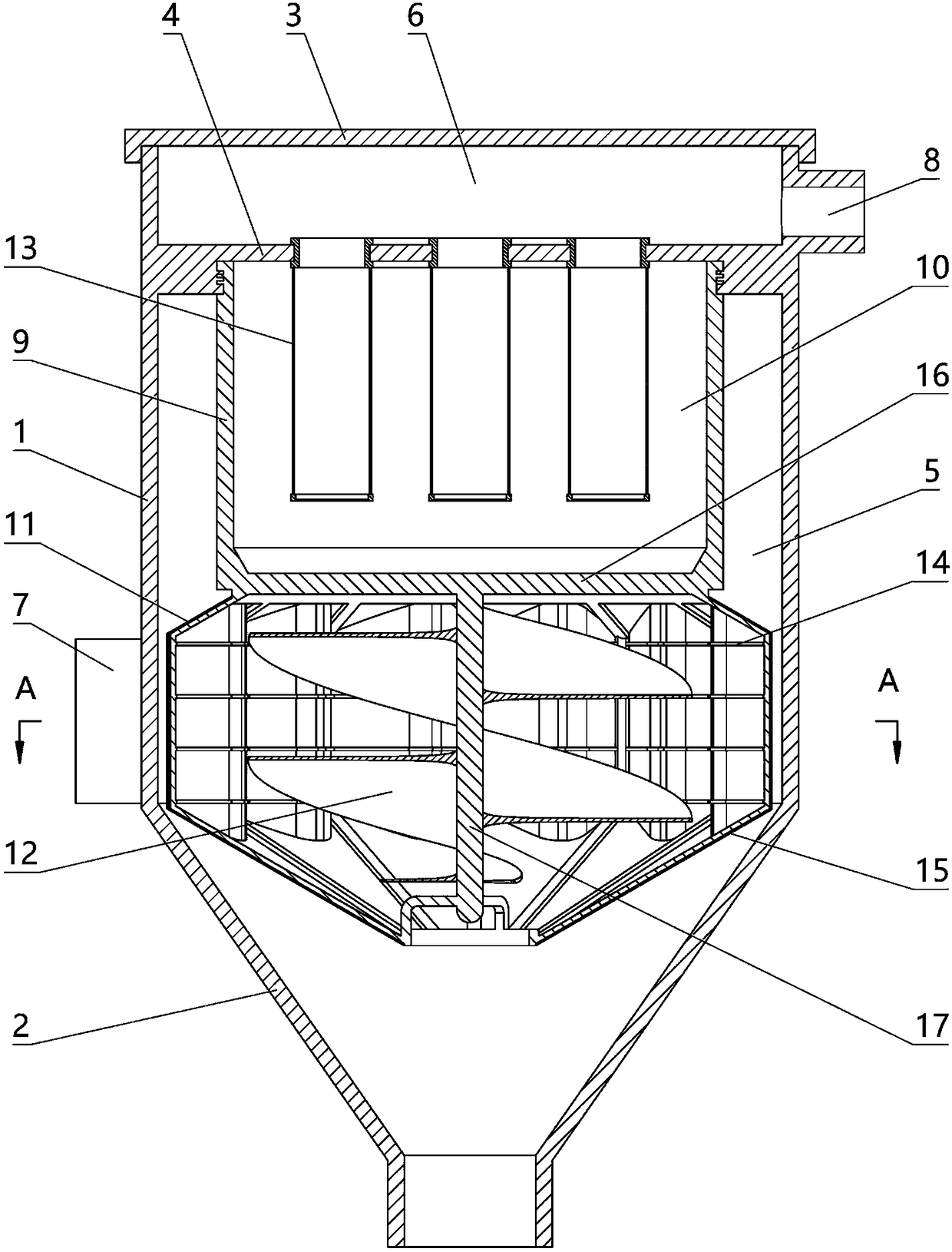

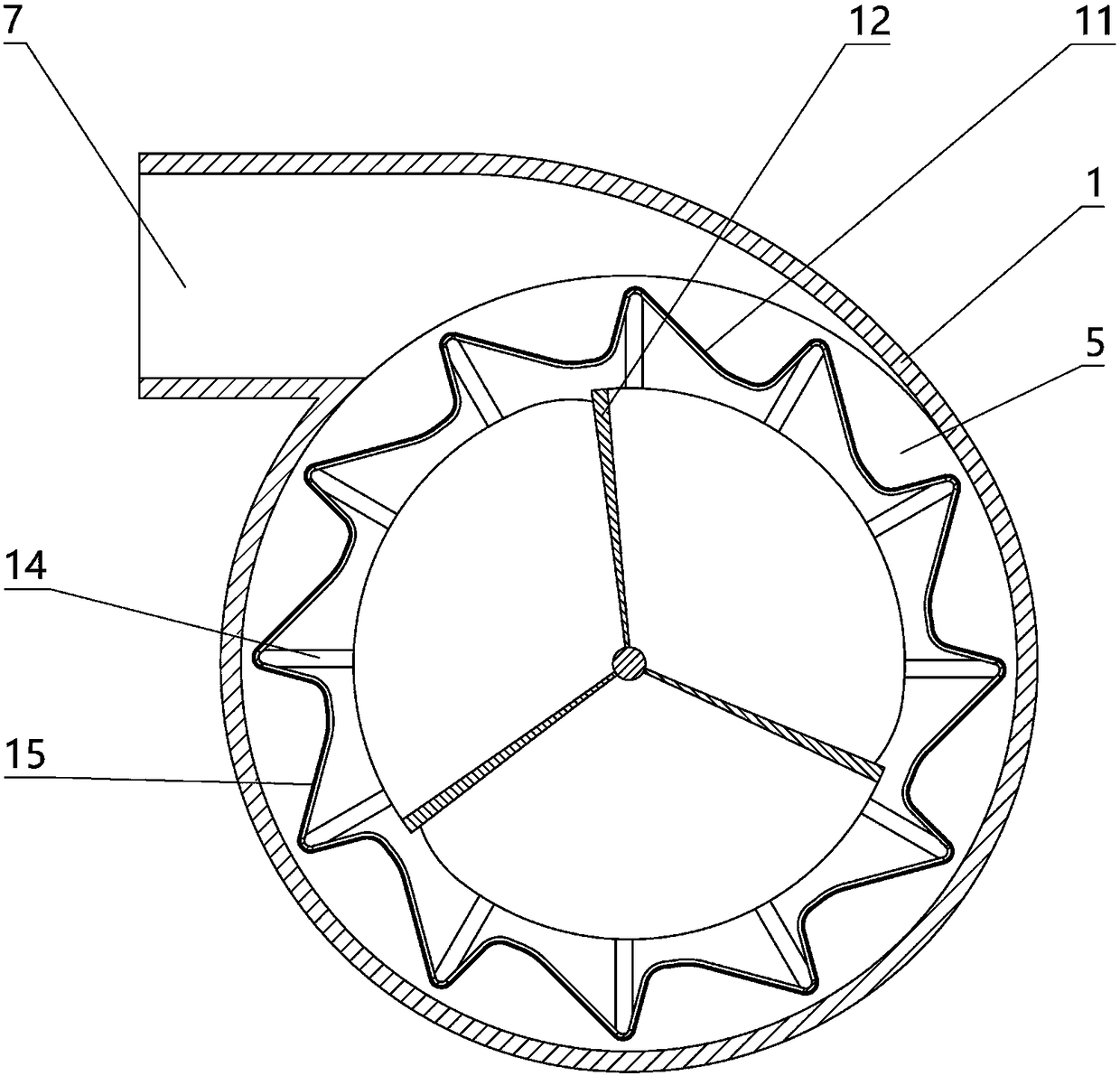

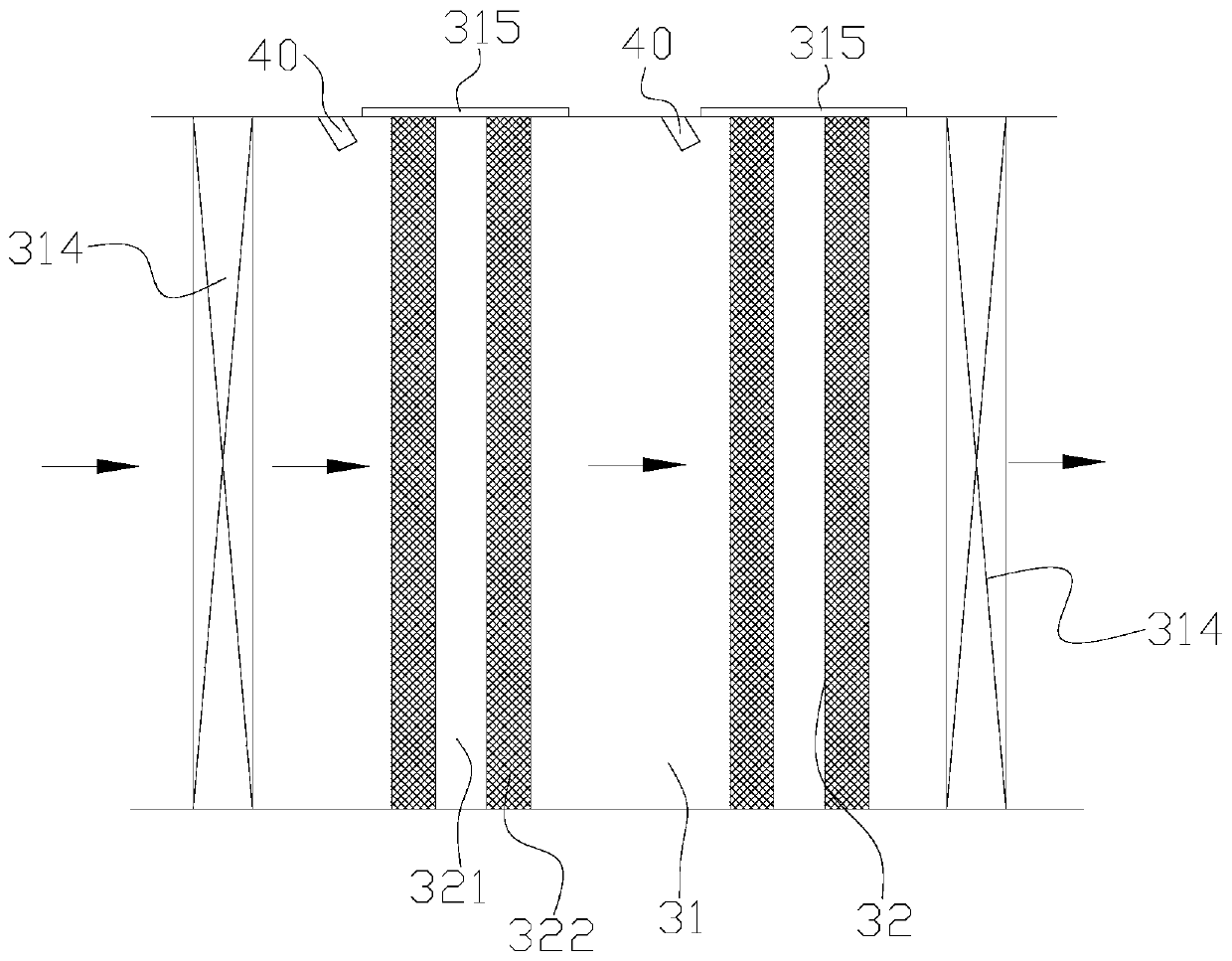

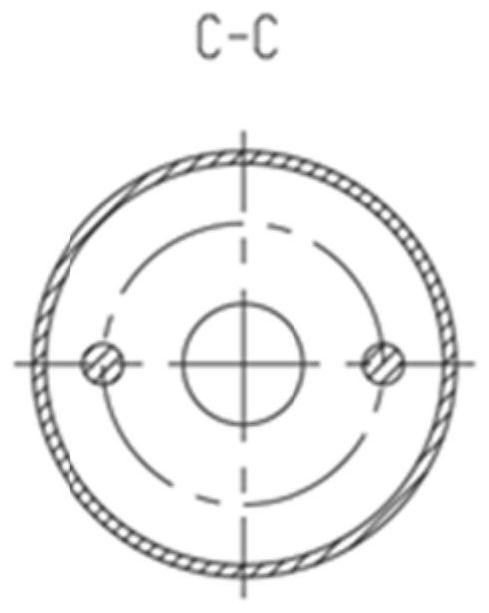

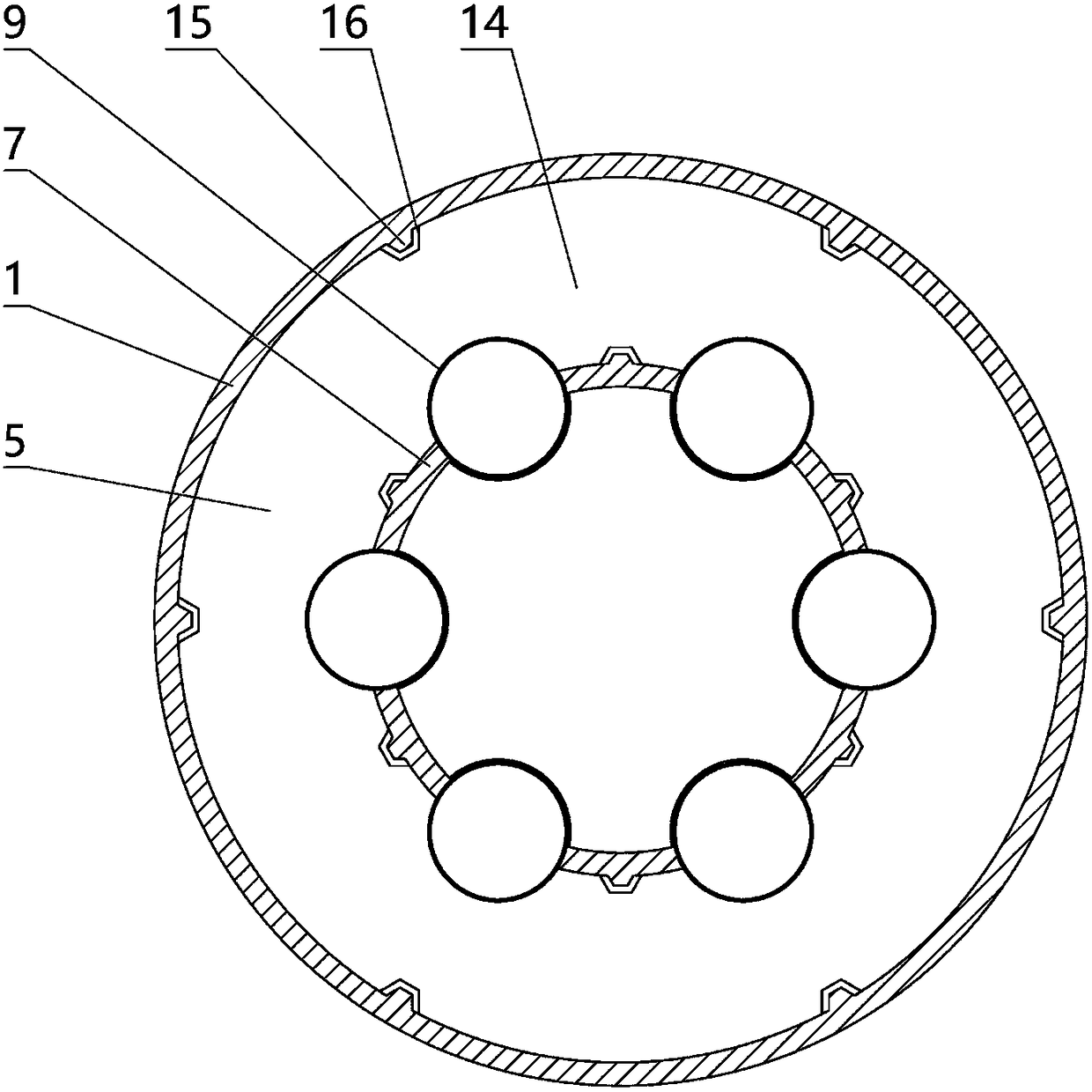

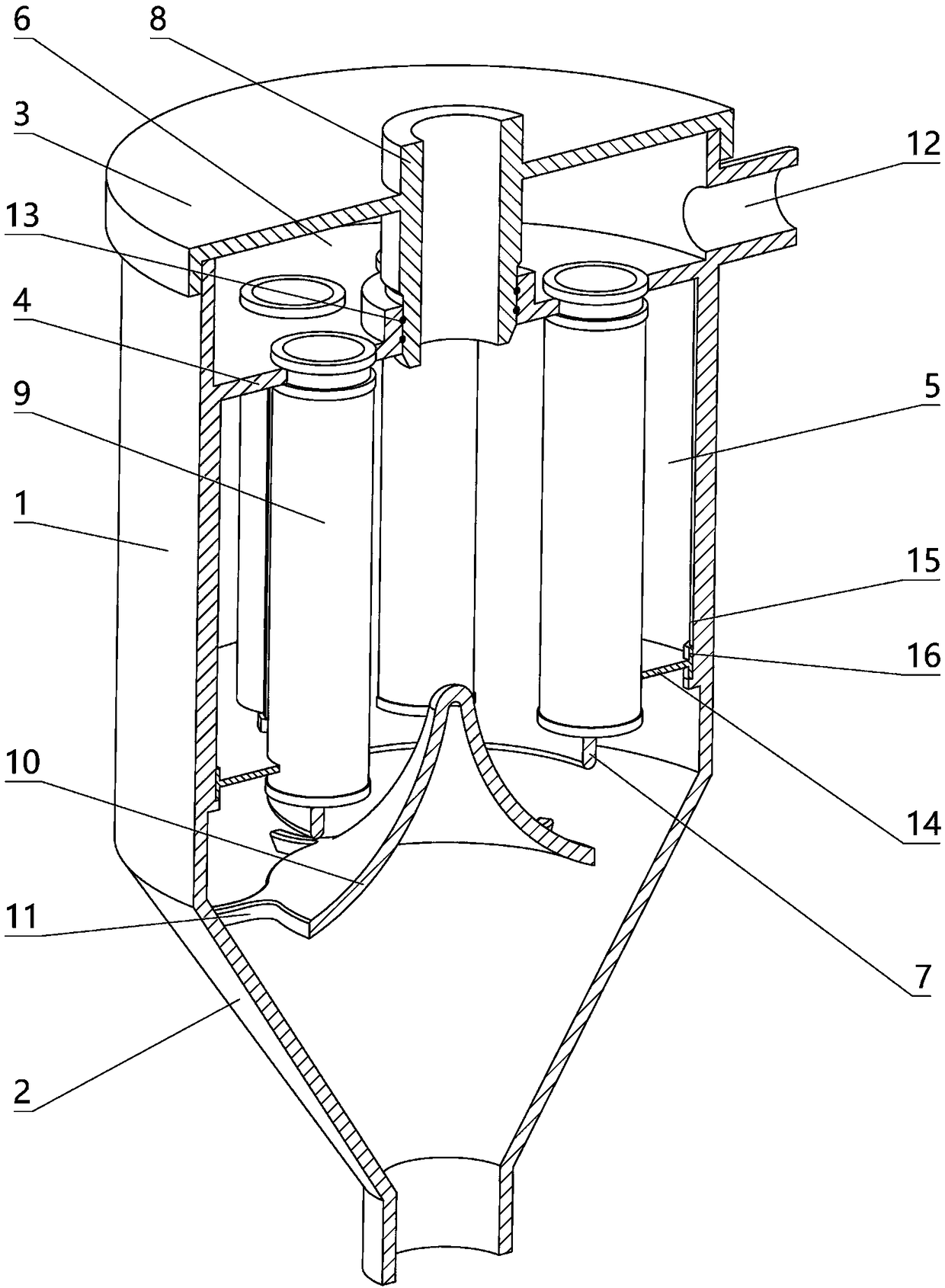

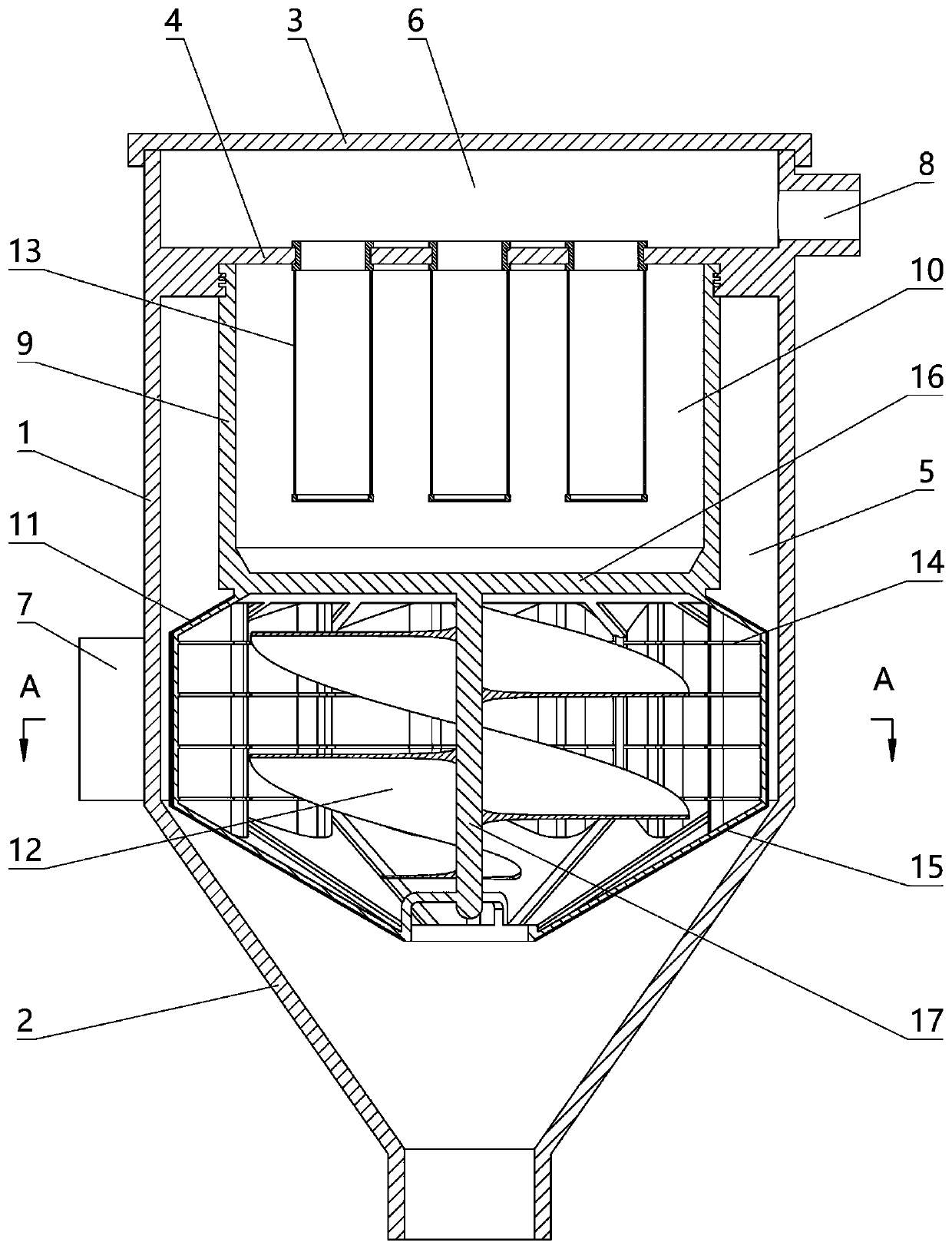

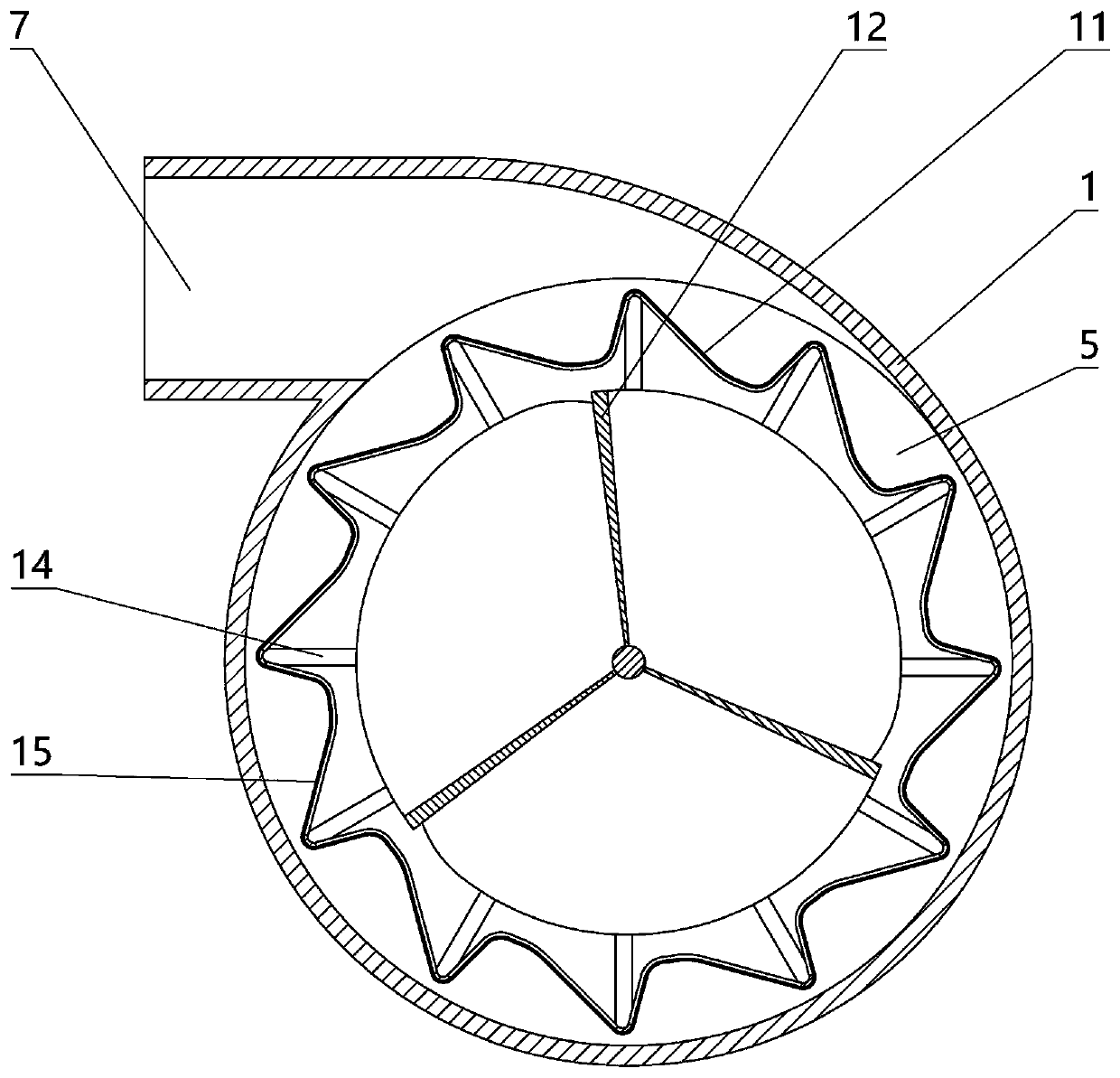

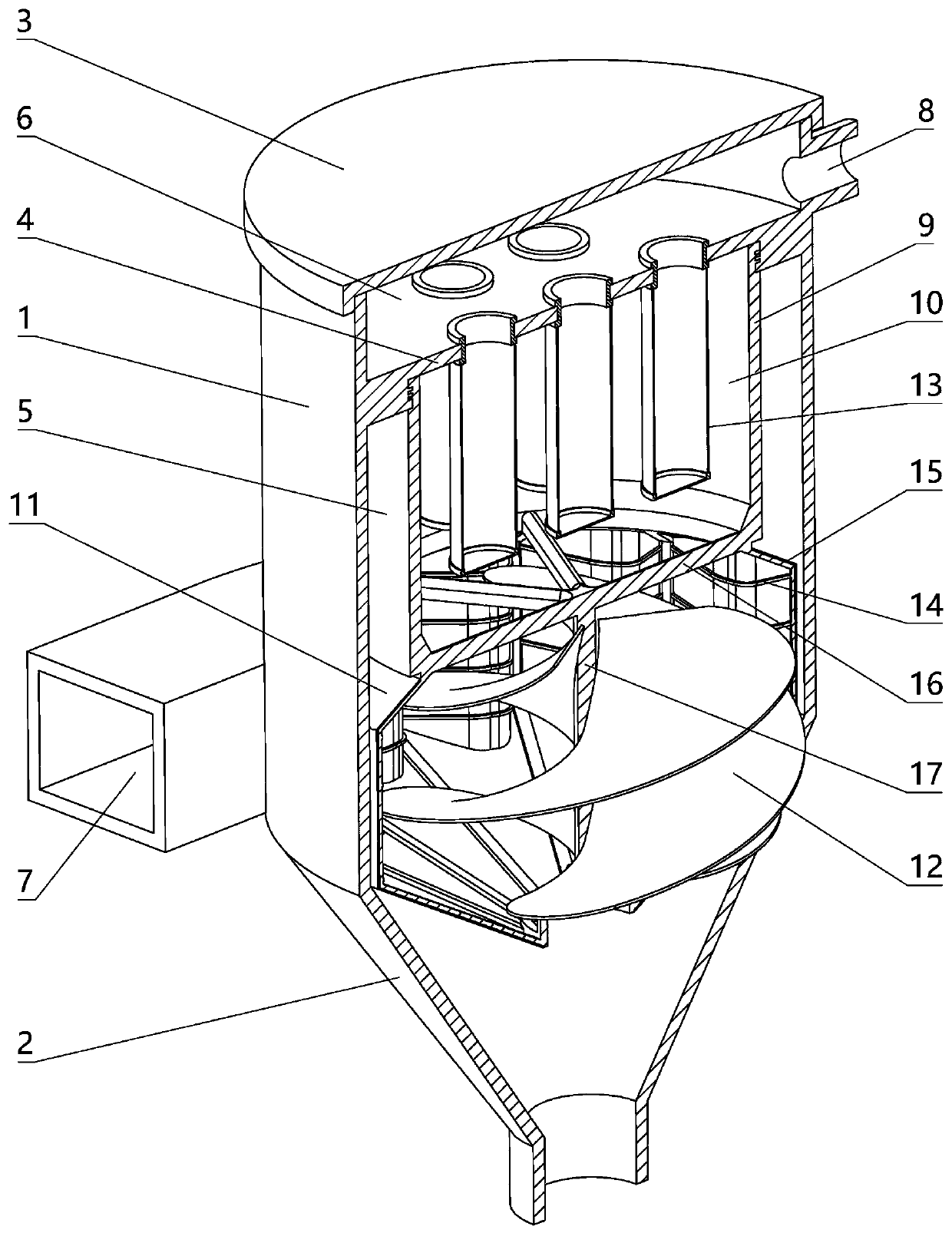

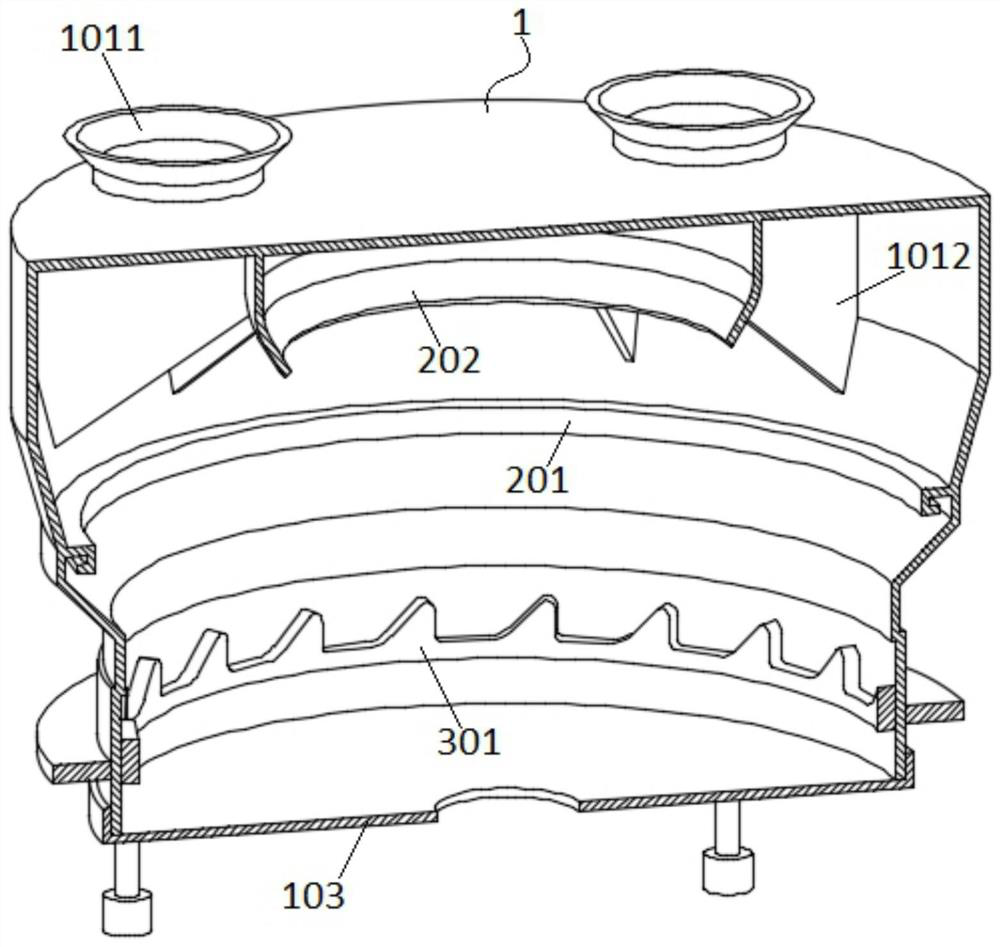

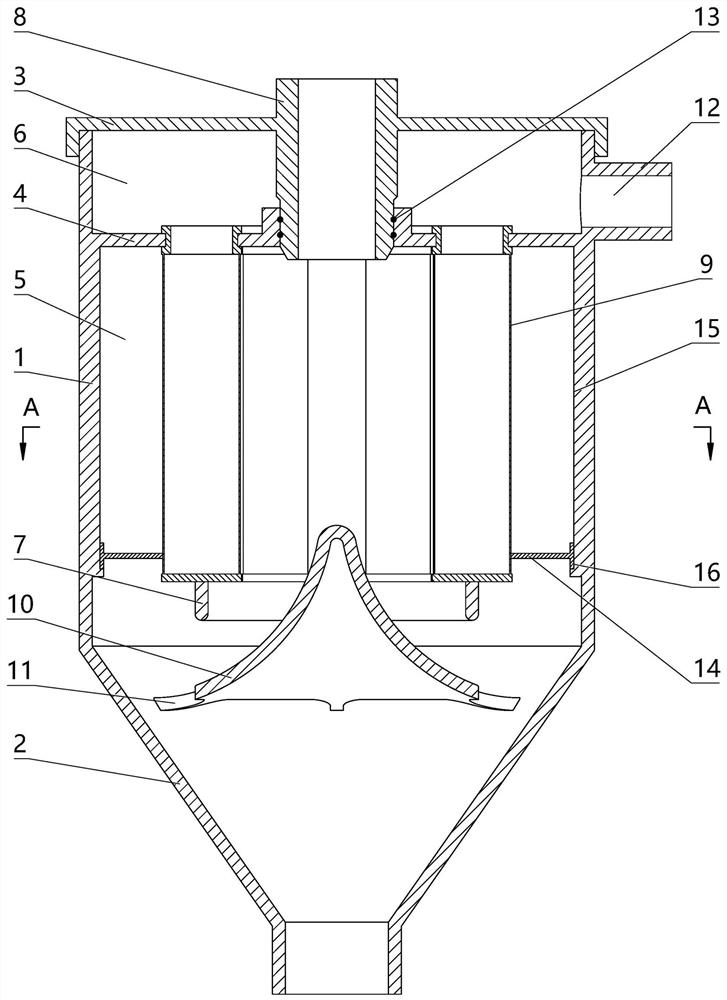

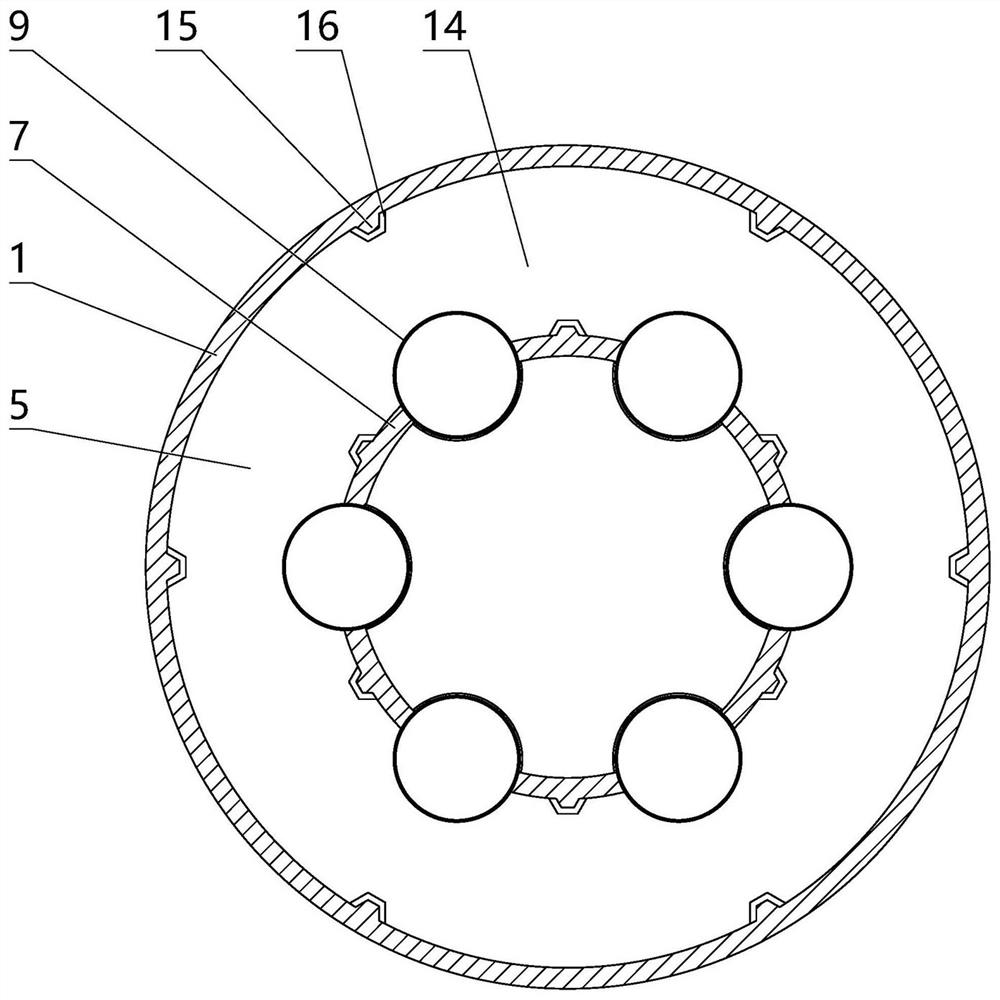

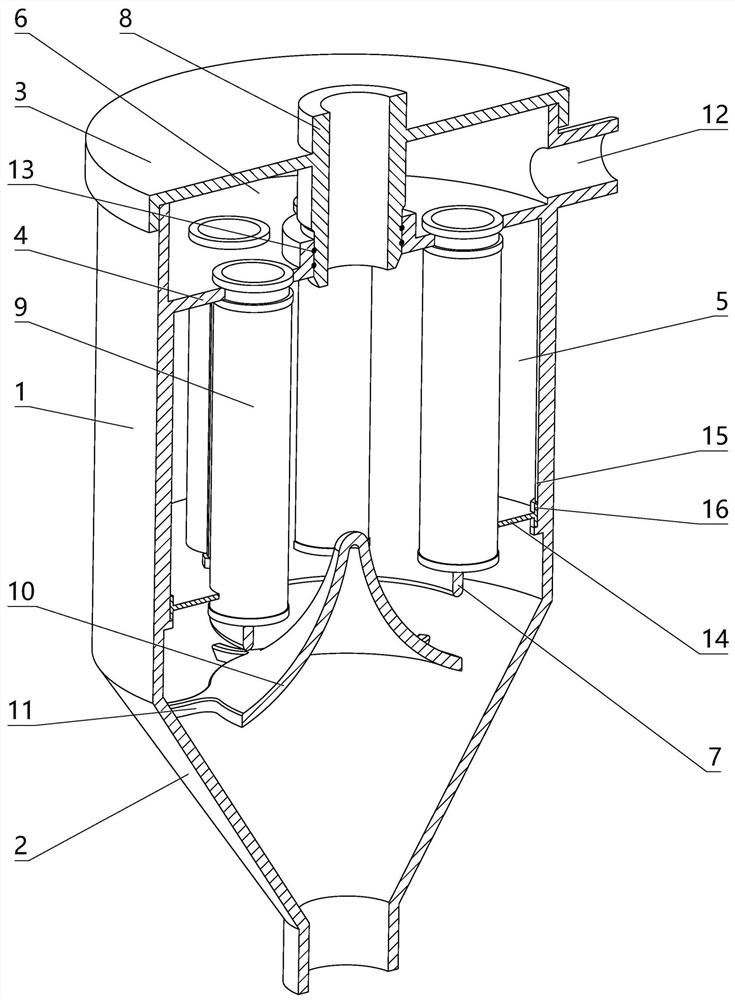

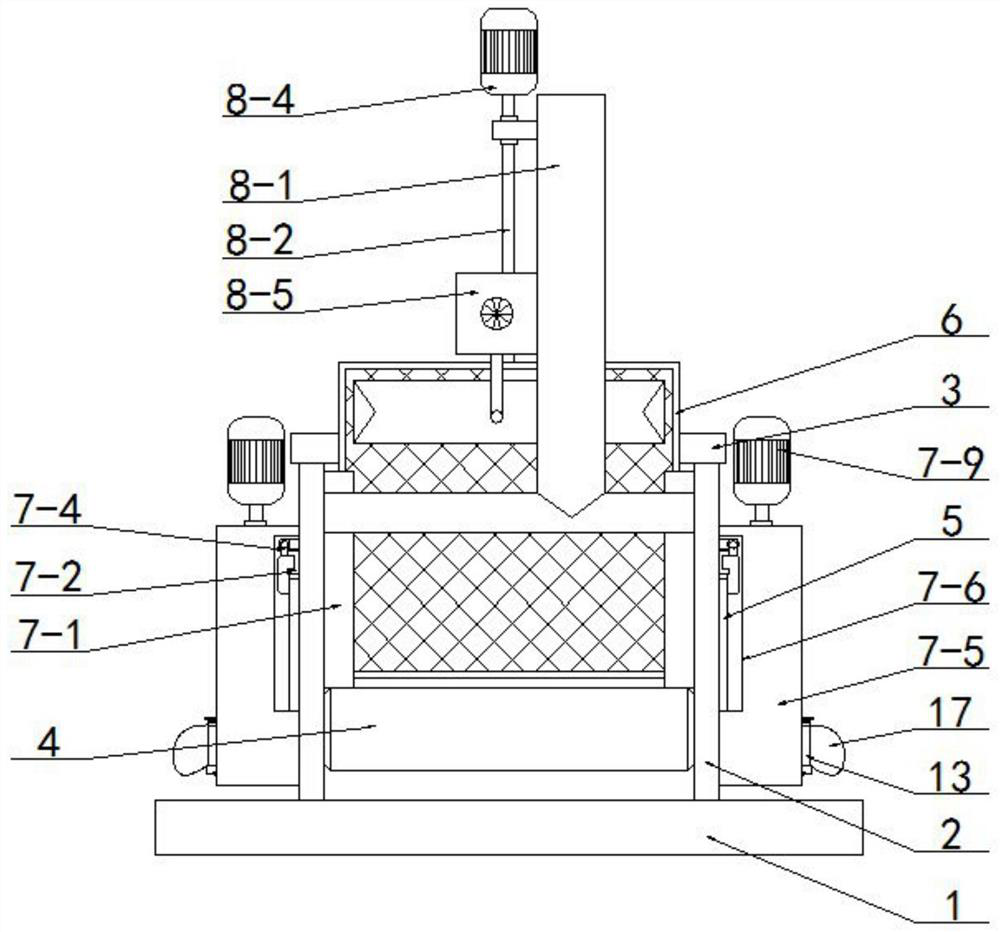

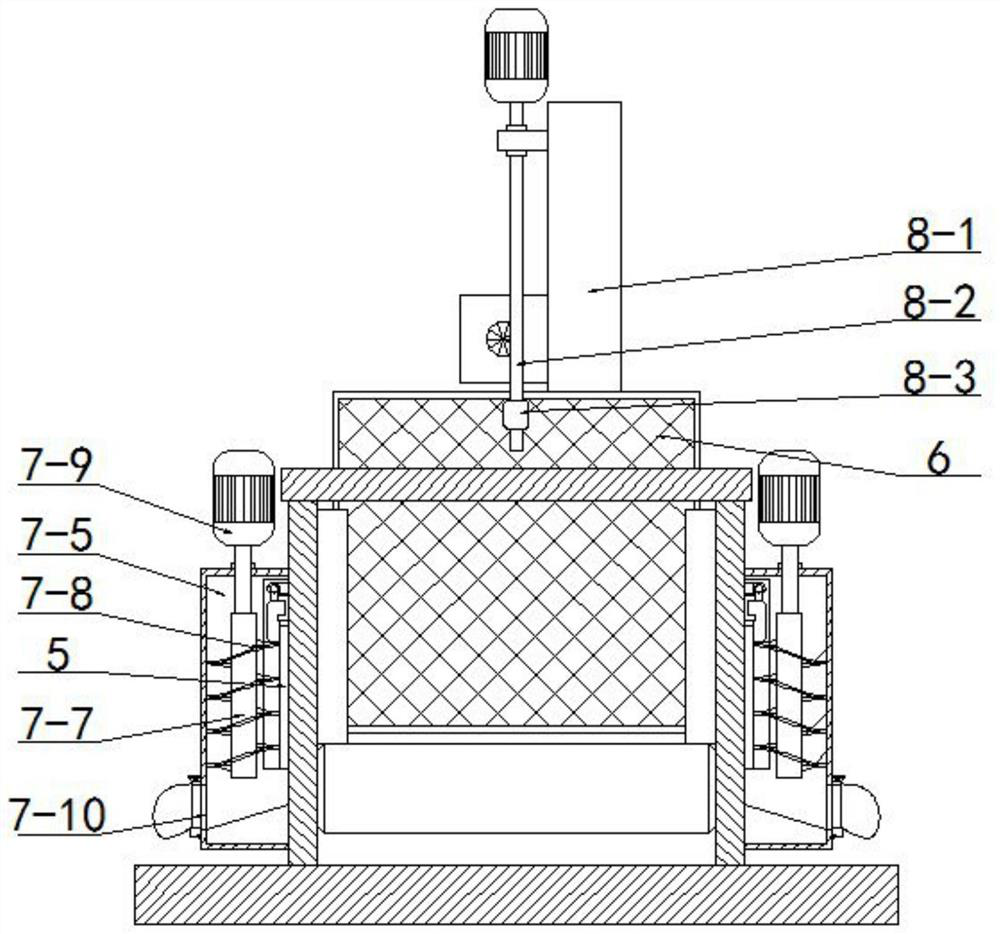

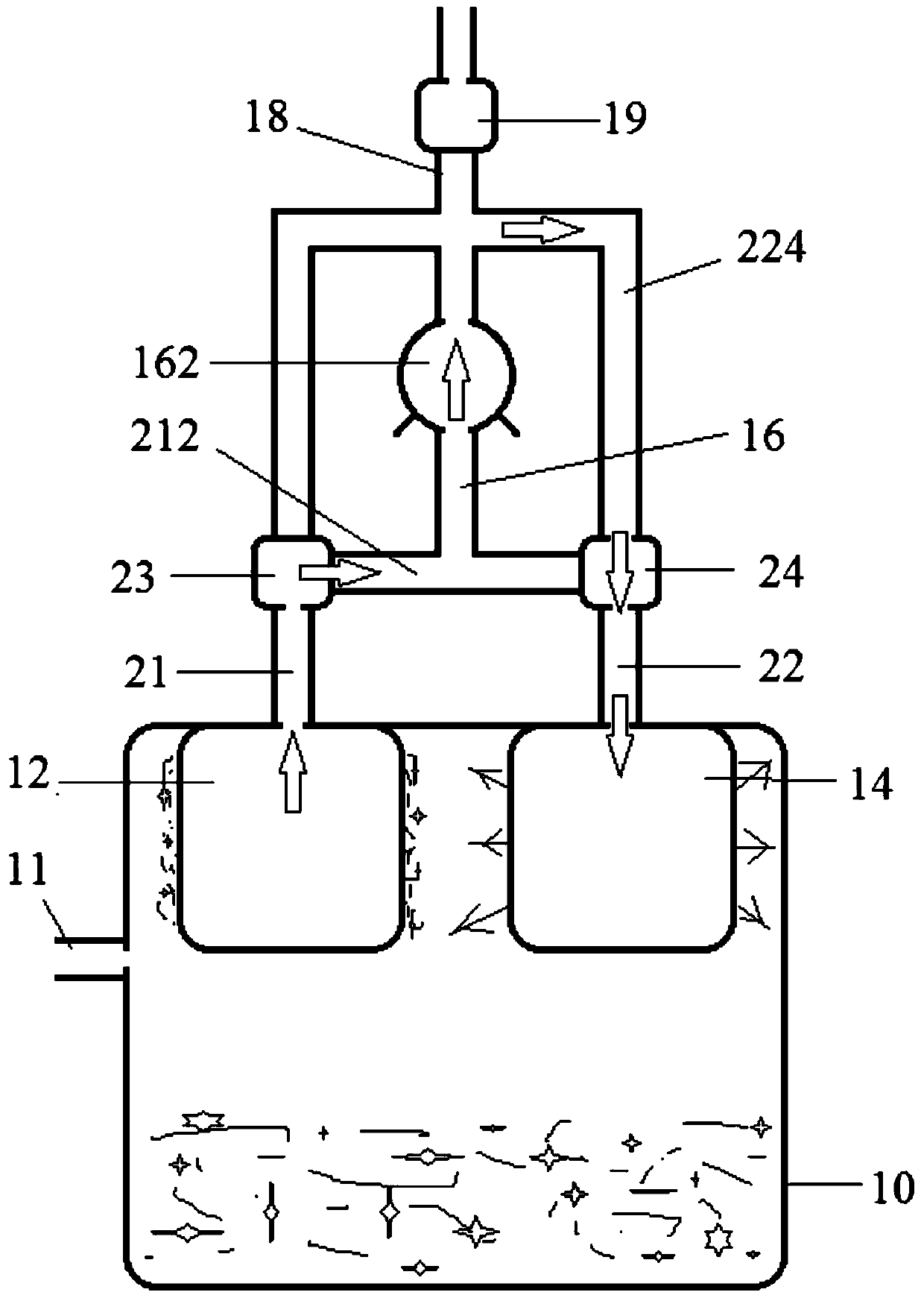

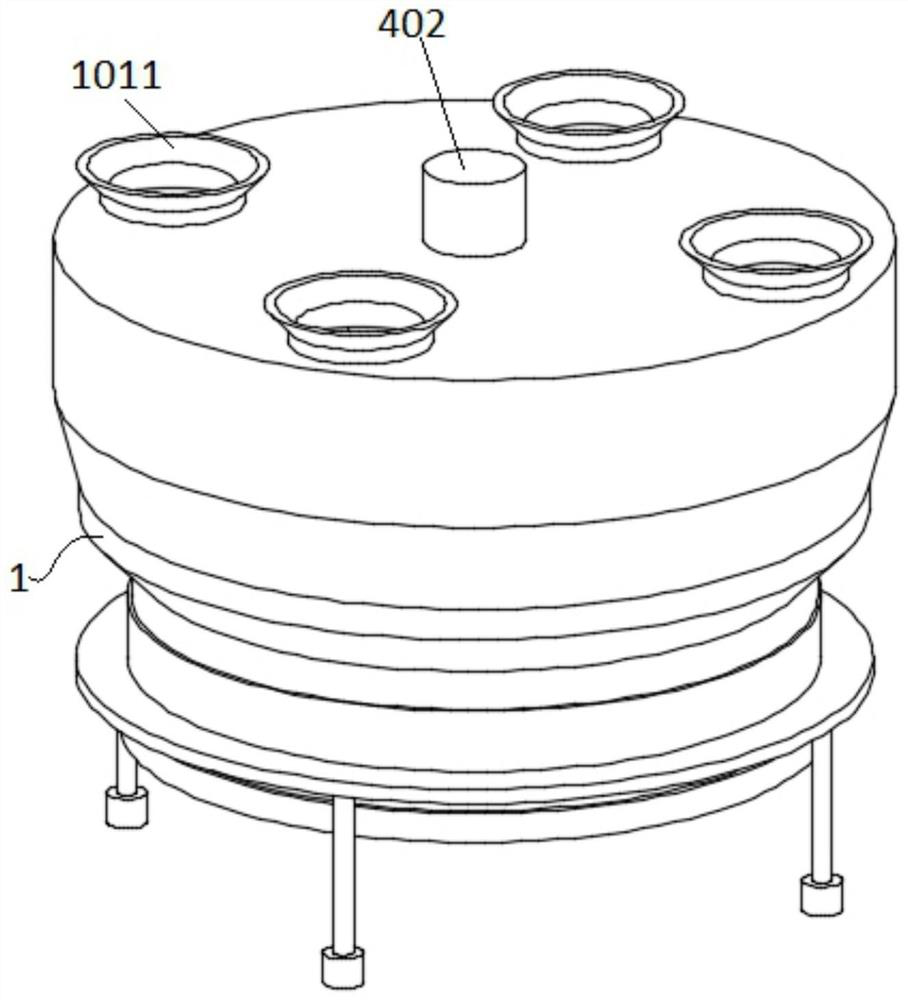

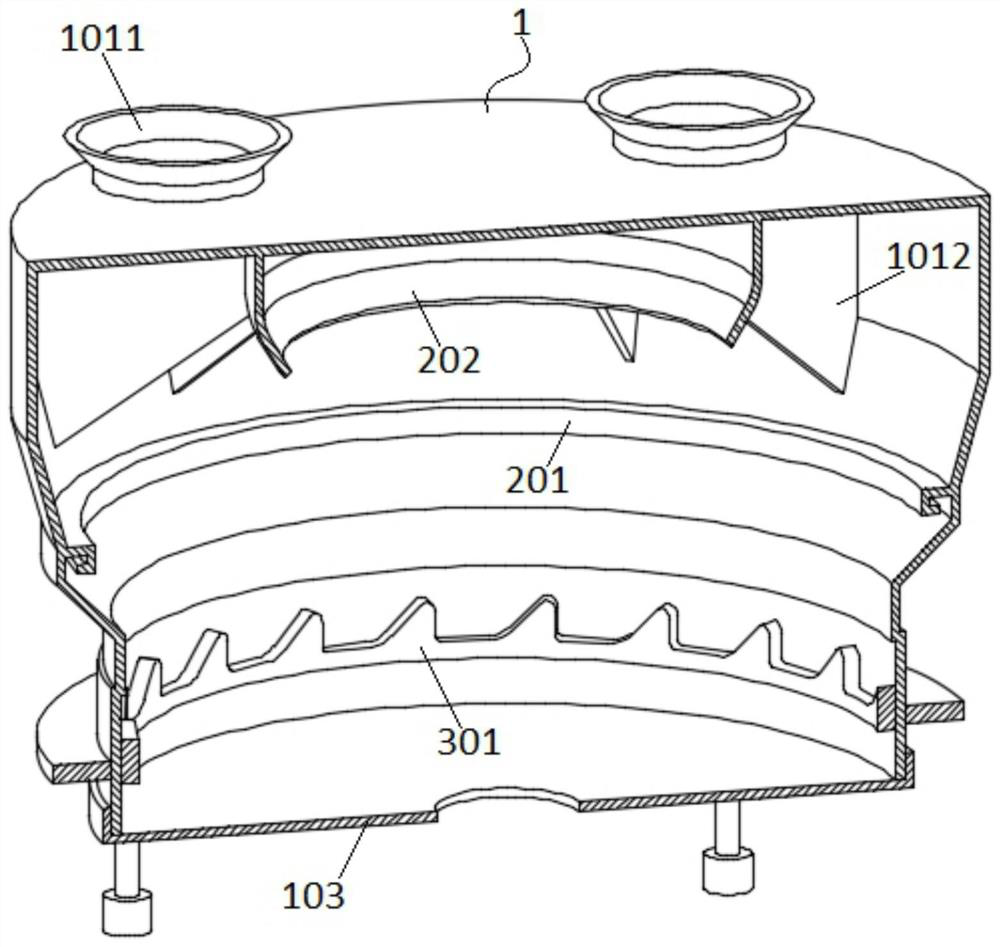

Multistage filtering deduster

ActiveCN108554108AEven and consistent airflowStable pressureCombination devicesPulp and paper industry

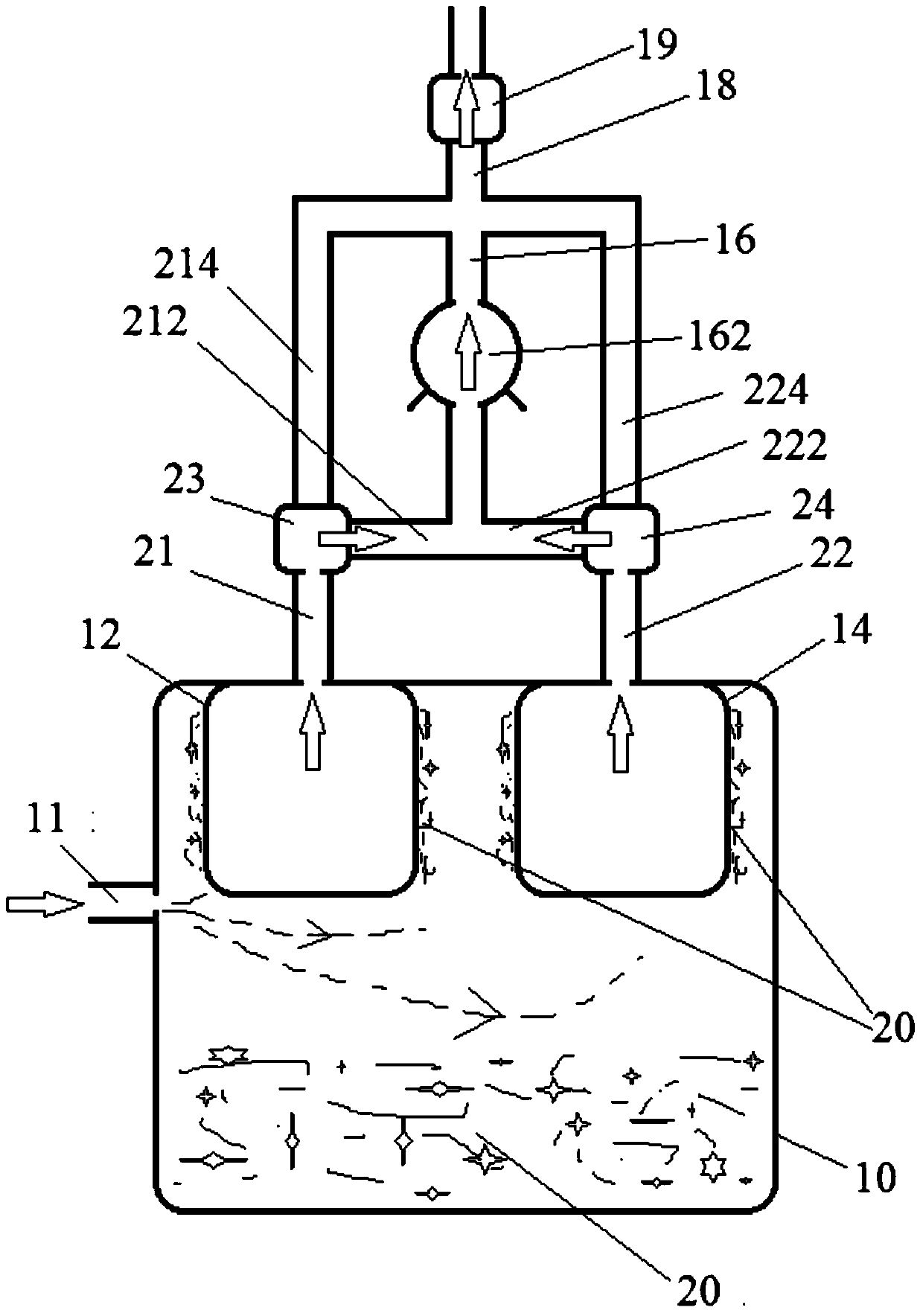

The invention relates to a multistage filtering deduster. The multistage filtering deduster comprises a shell, an ash bucket, a cover plate and a horizontally arranged separator plate mounted at the inner side of the shell, the separator plate divides the inner side of the shell into an upper part and a lower part which are not communicated, the ash bucket is mounted below the shell, the cover plate is mounted above the shell, a mixed flow chamber is formed among the shell, the ash bucket and the separator plate, a flow collecting chamber is formed among the shell, the cover plate and the separator plate, the shell is provided with an air inlet communicated with the mixed flow chamber, and the shell is provided with an air outlet communicated with the flow collecting chamber; the separatorplate is provided with an axially-vertically-arranged inner cylinder placed in the mixed flow chamber, the inner cylinder is rotatably connected with the separator plate, and a flow guiding chamber is formed at the inner side of the inner cylinder; the inner cylinder is provided with a special-shaped filter bag with opened top and bottom, placed below the inner cylinder, the vertical position ofthe special-shaped filter bag corresponds to the position of the air inlet, and the inner cylinder is provided with a pressurization fan placed at the inner side of the special-shaped filter bag; andthe separator plate is provided with a plurality of vertically-arranged micro-porous filter bags placed in the flow guiding chamber, and the upper ends of the micro-porous filter bags upwards go through the separator plate and are connected with the separator plate.

Owner:XINYI HONGRUN QUARTZ SILICA POWDER

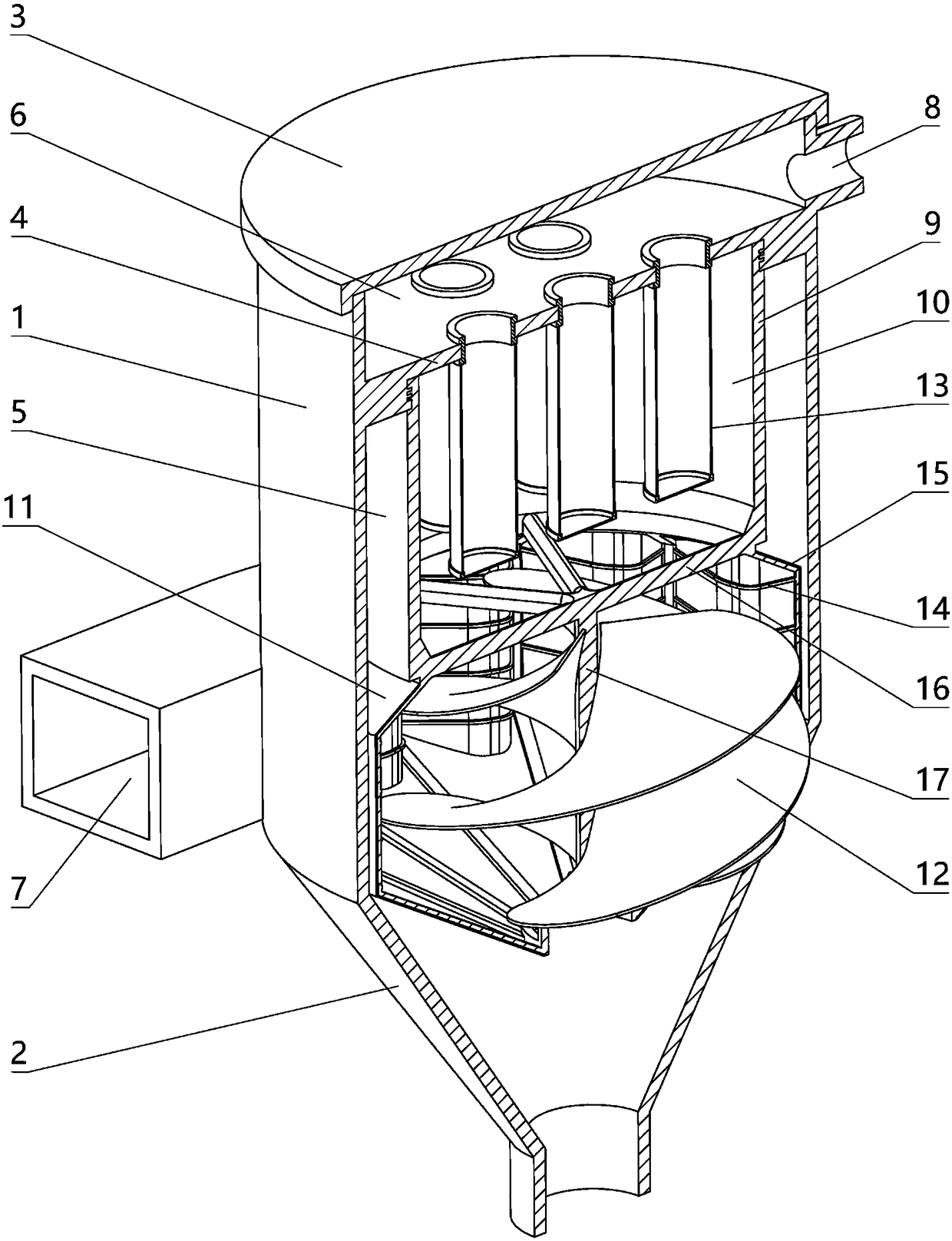

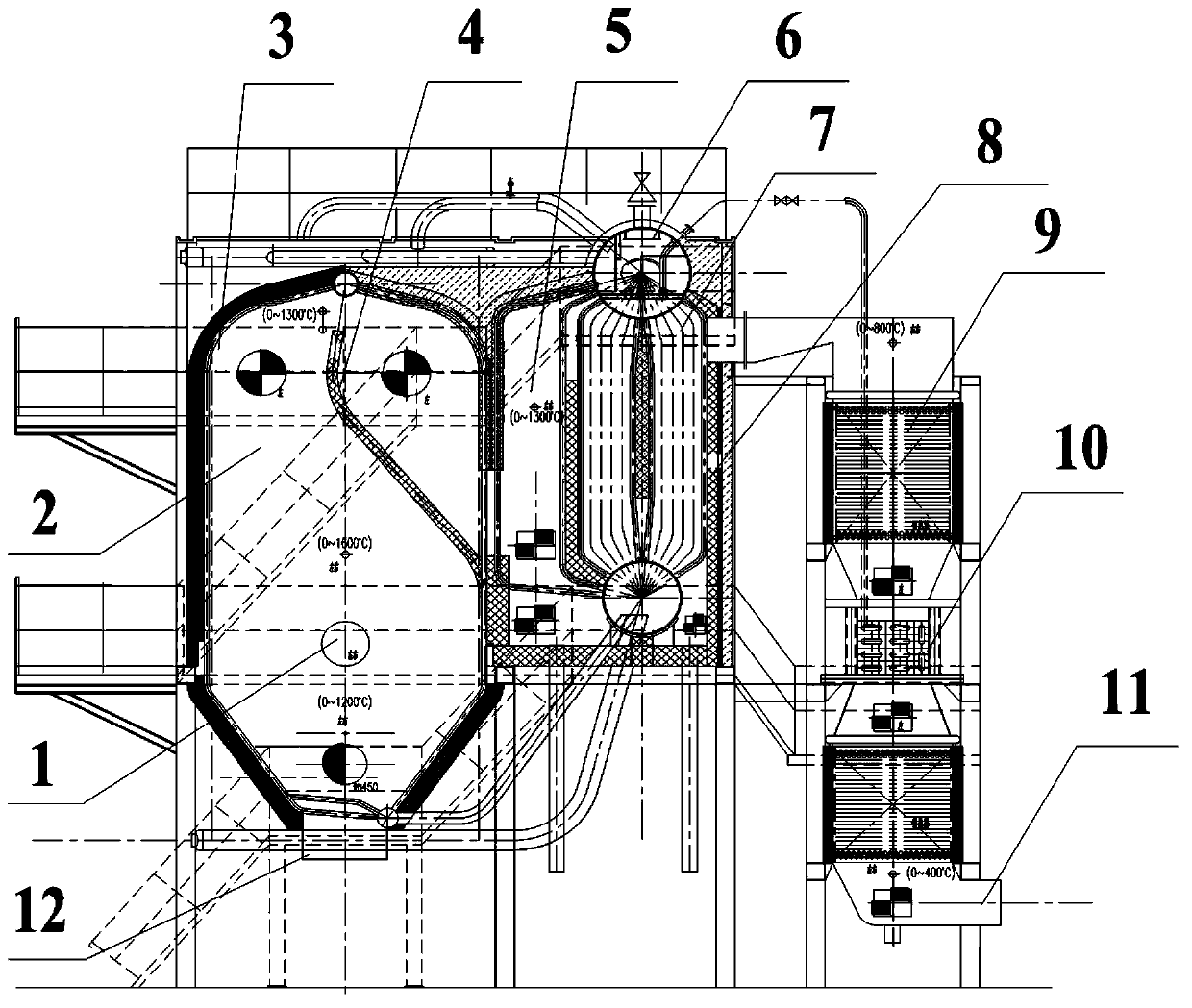

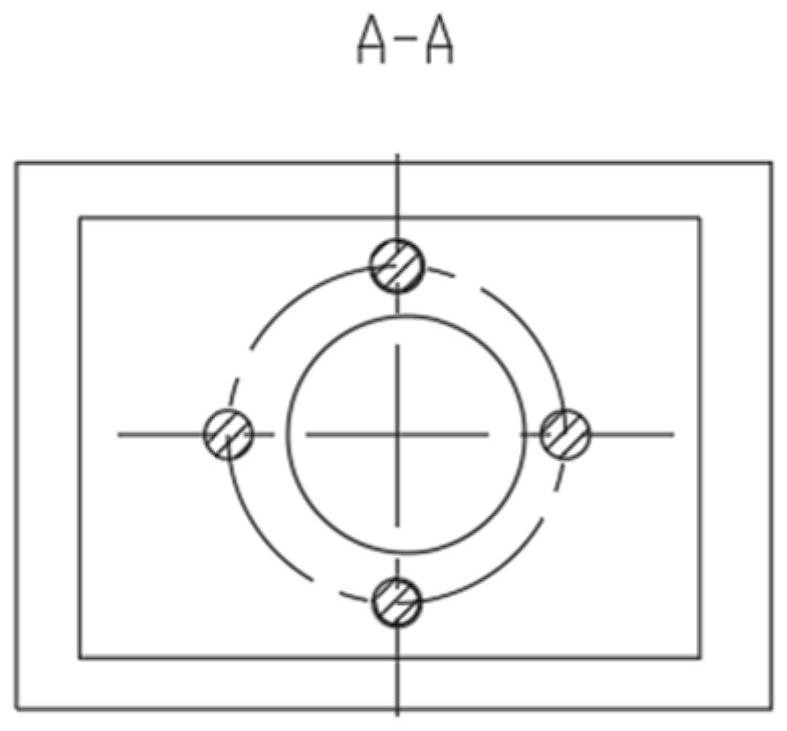

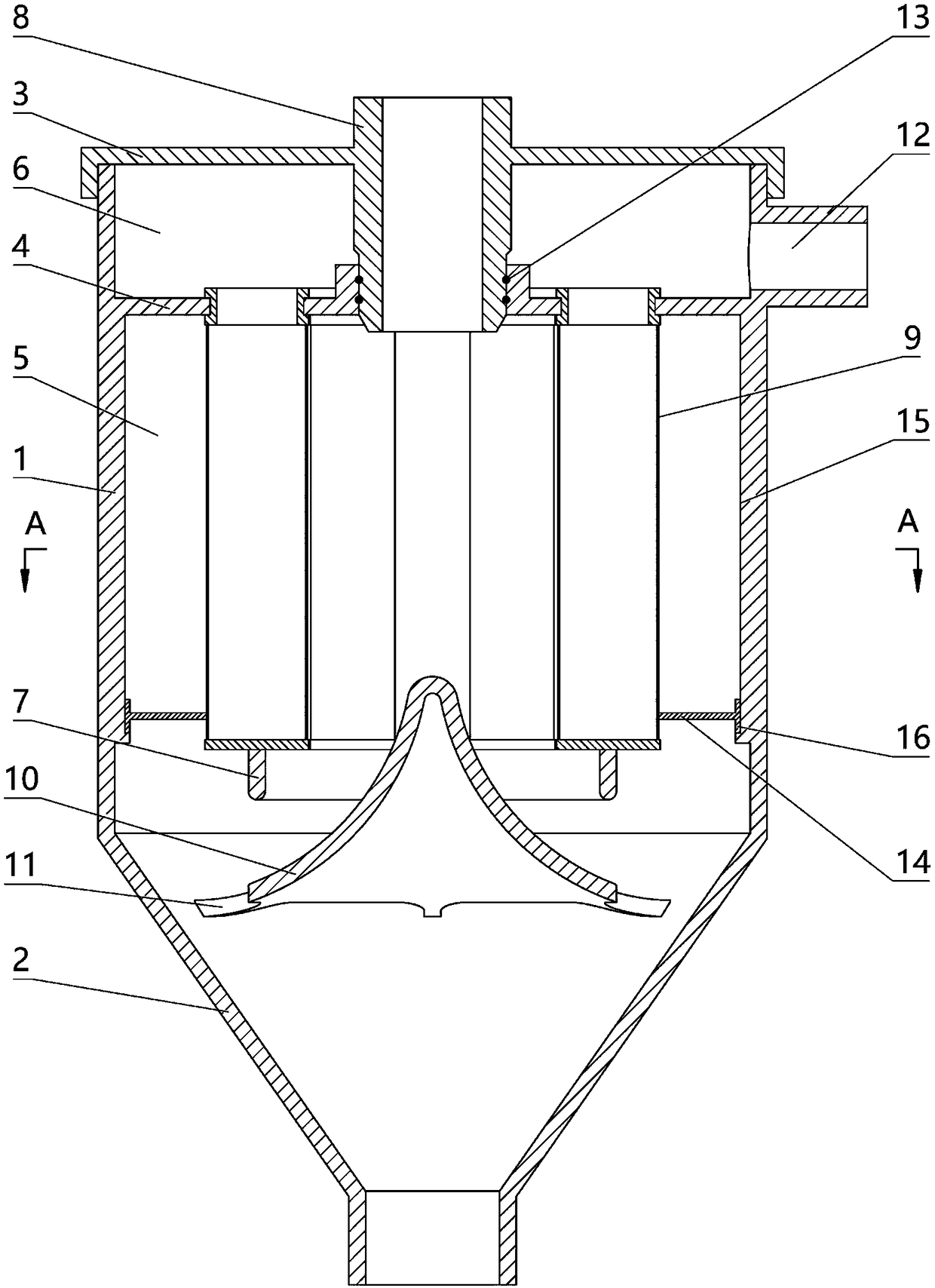

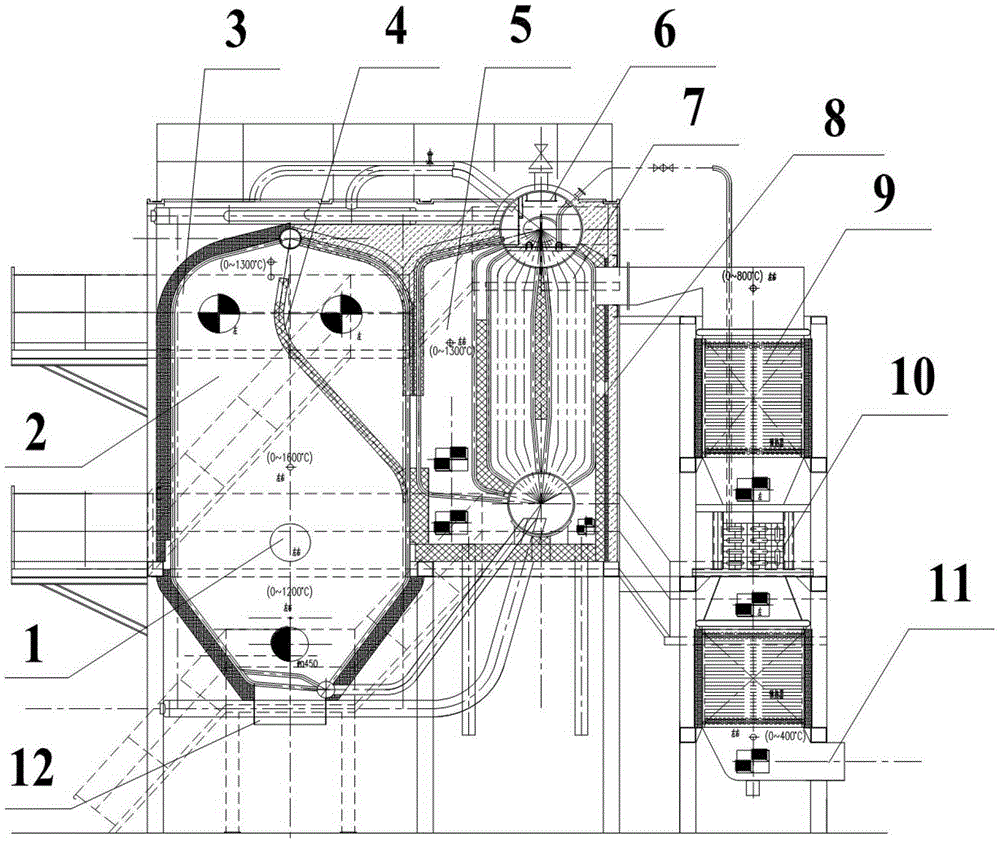

Clean pulverized coal combustion industrial boiler device

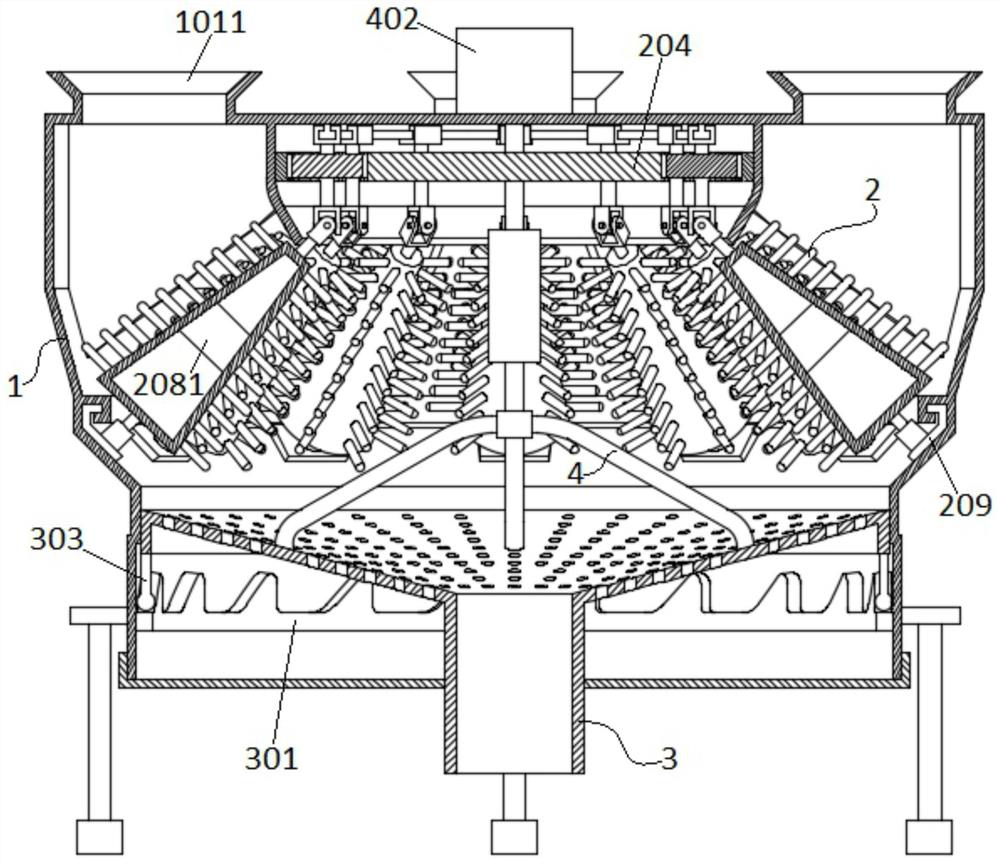

InactiveCN103388820AEnhanced Mixed BurnoutOvercome the defects of unsatisfactory combustion effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustor

The invention discloses a high-efficiency clean pulverized coal combustion industrial boiler device in the field of combustion devices with combustors. The high-efficiency clean pulverized coal combustion industrial boiler device comprises a hearth, a cyclone pulverized coal burner, a high-temperature vortex burnout device, a transition chamber, a convection flue and a tail flue, wherein the high-temperature vortex burnout device is arranged at an upper outlet of the hearth; the cyclone pulverized coal burner is arranged on the front and rear walls or the left and right walls on the lower part of the hearth in a hedge mode; the transition chamber is arranged on the rear part of the high-temperature vortex burnout device; the inlet of the convection flue is connected with the rear part of the transition chamber; the outlet of the convection flue is connected with the tail flue. According to the device, the defect that the organizing combustion effect in a short and small space of an industrial boiler is not ideal is overcome.

Owner:SHANGHAI JIAO TONG UNIV

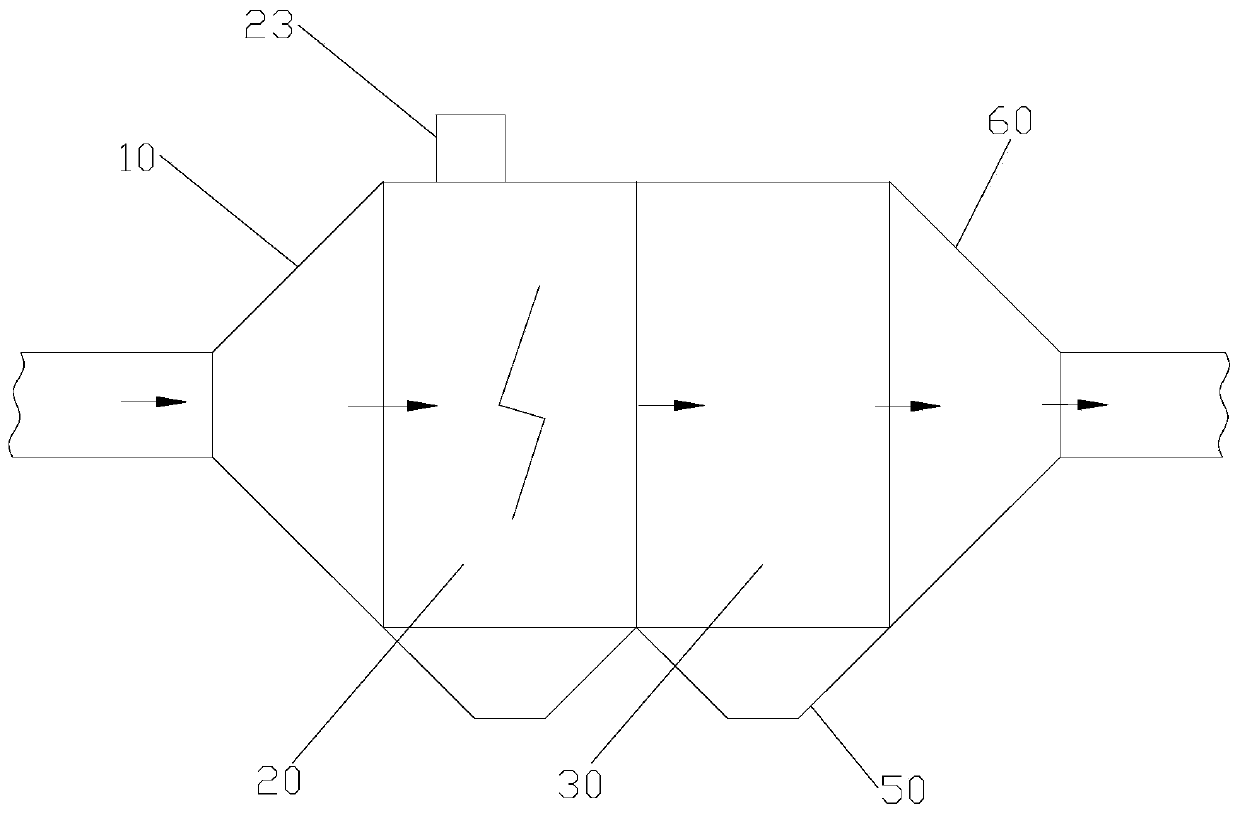

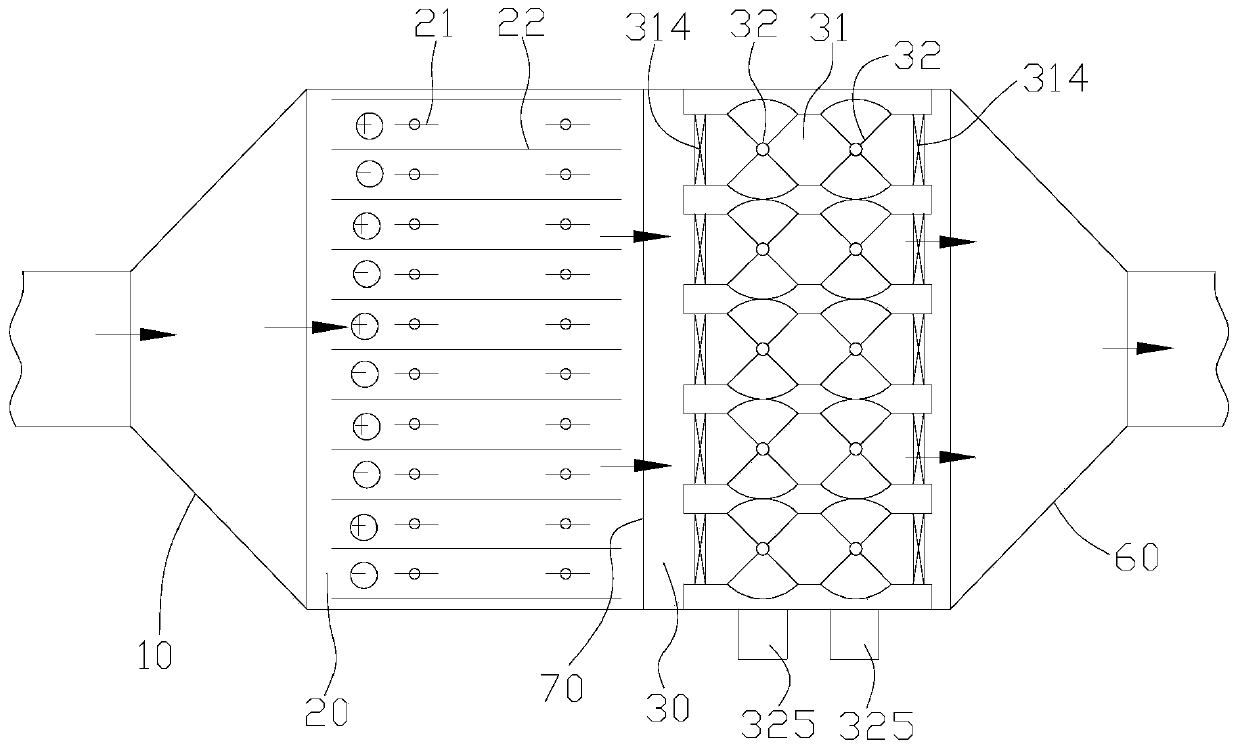

Ultra-clean electrostatic-fabric integrated precipitator

ActiveCN110314477AImprove dust removal efficiencyUnlimited lengthCombination devicesFlue gasEngineering

The invention discloses an ultra-clean electrostatic-fabric integrated precipitator. The precipitator comprises an electric field area and a bag dust removal area arranged in the back of the electricfield area; the bag dust removal area comprises a plurality of mutually parallel flue gas channels, the walls of the flue gas channels are parallel to the height direction of the bag dust removal area; in the flue gas flow direction, at least one first metal filtering component is arranged in each flue gas channel, and each first metal filtering component includes a shaft perpendicular to the fluegas flow direction and multiple metal meshes which are distributed in the circumferential direction of the shaft; the shafts can rotate and are arranged to be that flue gas flowing into the flue gaschannels passes through the metal meshes and then flows out of the flue gas channels, at least part of the flue gas flows through two or more metal meshes. According to the ultra-clean electrostatic-fabric integrated precipitator, the structure of a metal filter screen is improved, the flue gas can be filtered through at least two metal filter screen layers, and the dust removal efficiency is improved.

Owner:FUJIAN LONGKING

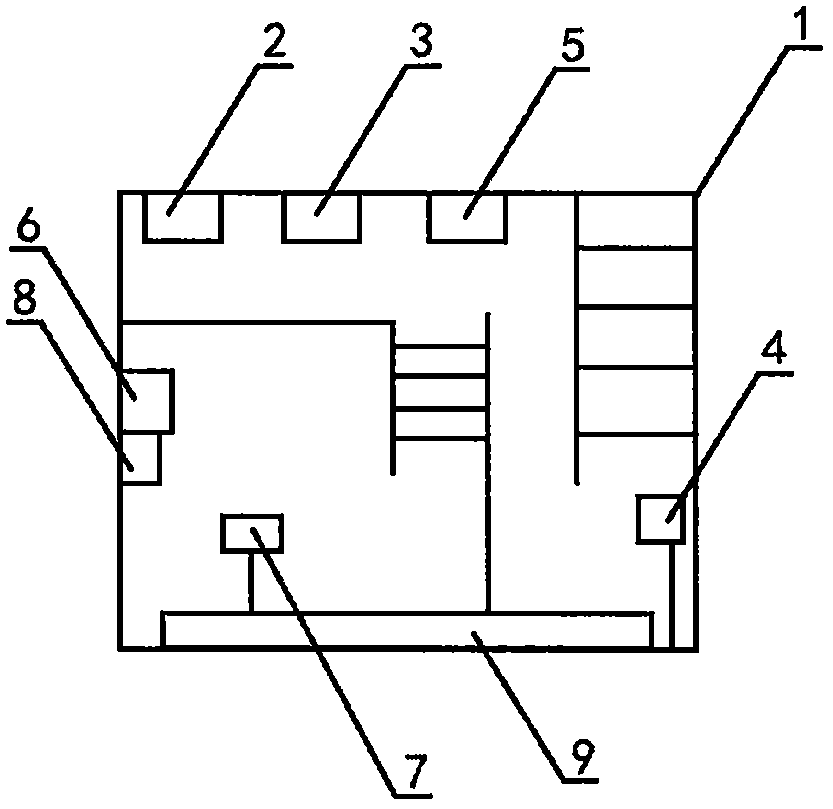

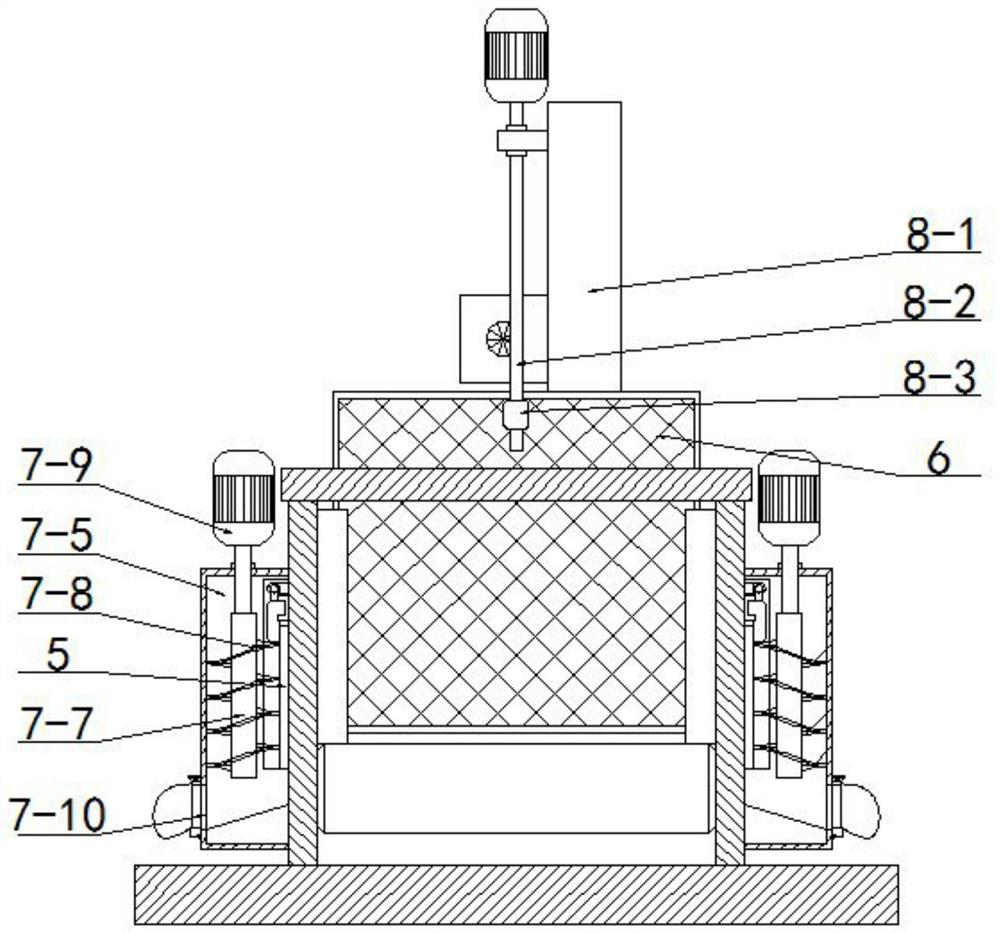

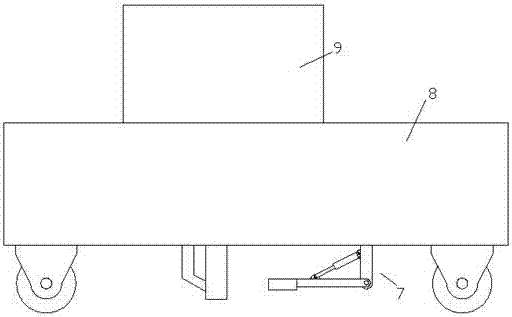

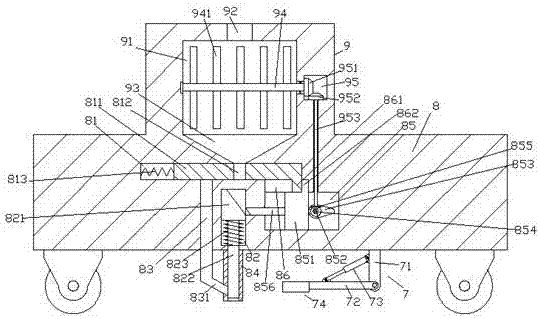

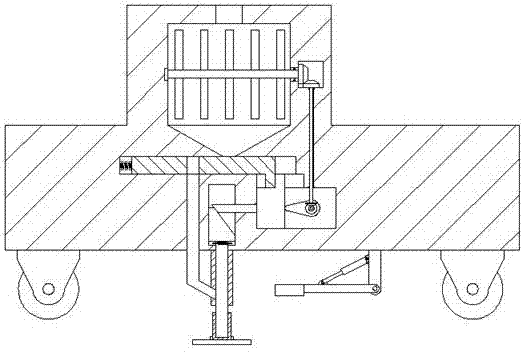

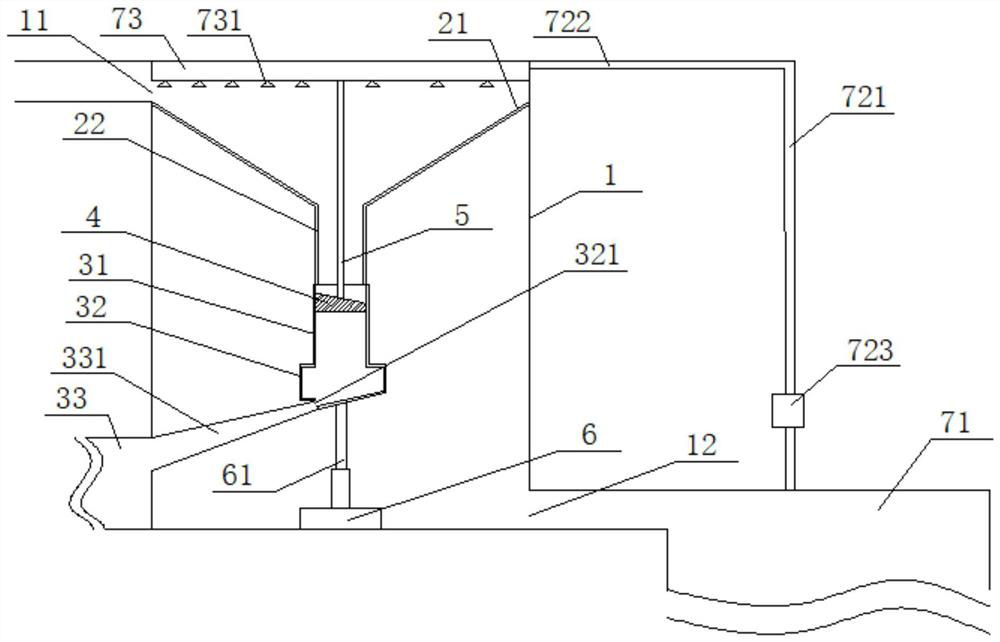

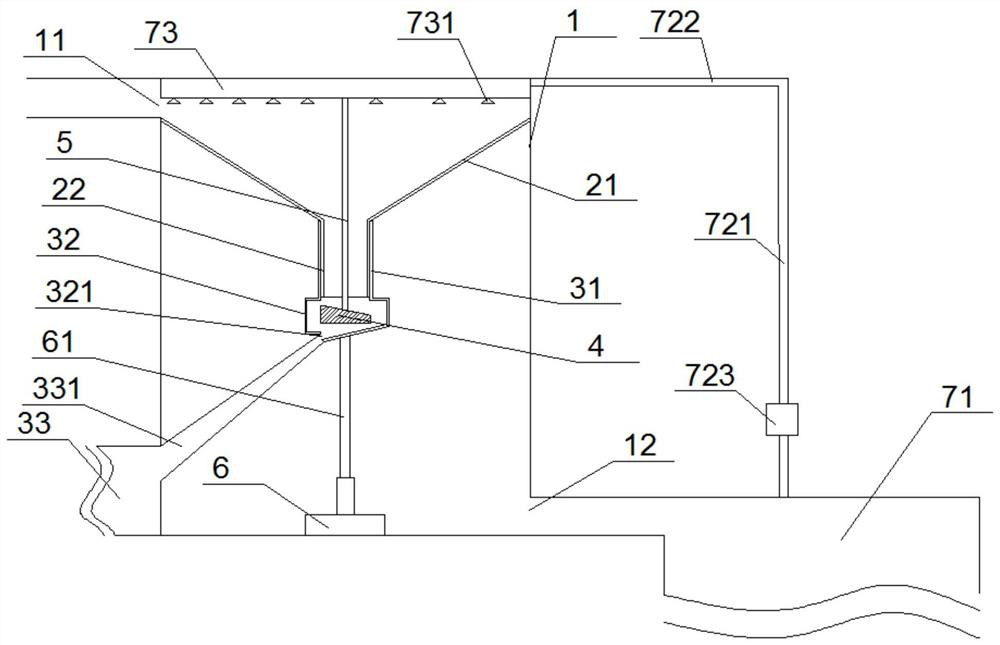

Hearth ash removing device of coal-fired boiler

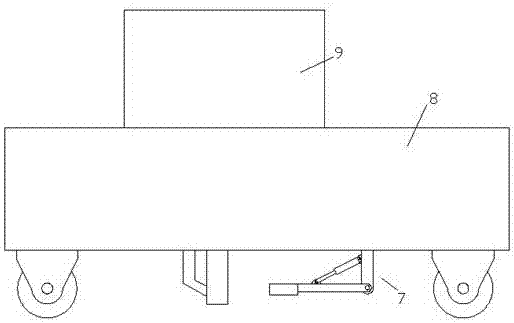

InactiveCN107869724ARealize cleaning operationImprove efficiencyLighting and heating apparatusBoiler furnaceBoiler slag

Furnace soot cleaning device for coal-fired boilers, including a body (1), on which a vibration device (2), a temperature sensing module (3), a slag scraping device (4), a transmission module (5), a management When the module (6) is running, the vibrating device (2) vibrates to make fine ash particles fall off, and the temperature sensing module (3) senses whether the temperature of the furnace reaches the standard, and the slag scraping device (4) can immediately scrape off The scum on the machine body is prevented from accumulating, and the management module (6) comprehensively processes various information sensed; a telescopic brush (7) is set, and heavy dust particles can be brushed first; a dust collection module is set (9), the removed ash particles can be processed; a prompt module (8) is provided to send a prompt when abnormal slagging or temperature abnormality in the boiler is detected.

Owner:XINCHANG CHENGTAN CHENGSHE MACHINERY FACTORY

Radiation-resistant pipeline laser cleaning device and using method

ActiveCN112827946AImprove flexibilityRealize cleaning operationHollow article cleaningDirt cleaningBeam expanderPlane mirror

The invention provides a radiation-resistant pipeline laser cleaning device. The radiation-resistant pipeline laser cleaning device comprises a laser transmission mechanism, a fixed support, a movement mechanism, a guide dust collection device and a cleaning mechanism, wherein the emitting side of the laser transmission mechanism sequentially penetrates through the movement mechanism and the guide dust collection device and is connected with the cleaning mechanism; the guide dust collection device comprises a vacuum dust collection device, a guide wheel mechanism and a bolt, the guide wheel mechanism is arranged on the outer side of the vacuum dust collection device, and the bolt is used for fixing the guide wheel mechanism on the front end surface of the movement mechanism; and the cleaning mechanism comprises a beam expander, a plane mirror, a galvanometer unit and a focusing device which are arranged at an outlet of an optical fiber air pipe, and the plane mirror is arranged right ahead of the beam expander and is connected with the inner wall of the cleaning mechanism. According to the radiation-resistant pipeline laser cleaning device, the movement mechanism acts on the cleaning mechanism to rotate and feed at the same time, so that light beams focused on the inner wall of a pipeline to be cleaned do spiral motion, and the defect that the cleaning device cannot adapt to a cleaning environment with a high radiation dose rate is overcome; and a first supporting rod in a movement unit is hinged to the end surface between two supporting plates, so that good flexibility is achieved.

Owner:HUNAN UNIV

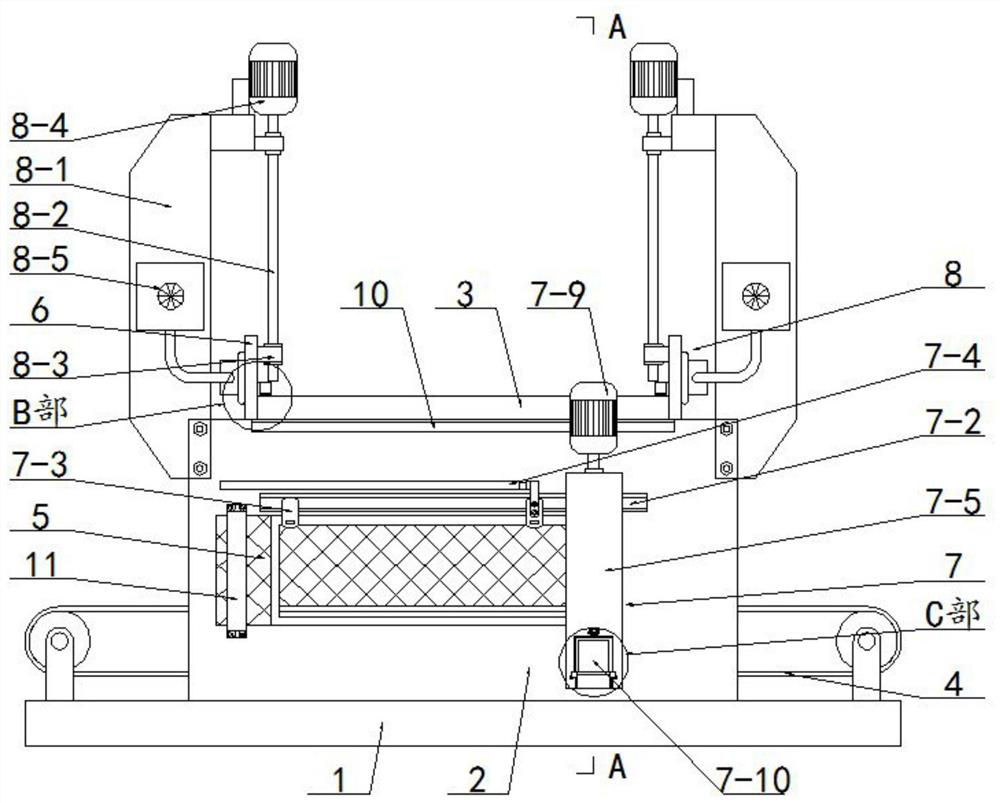

Novel bag type dust remover

ActiveCN108854295ARealize cleaning operationSimple and fast cleaning operationCombination devicesDispersed particle filtrationMixed flowBaghouse

The invention relates to a novel bag type dust remover which comprises a shell body, a dust bucket, a cover plate and a partition plate, wherein the partition plate is horizontally arranged on the inner side of the shell body, the inner side of the shell body is divided into two parts by the partition plate, the two parts are not communicated up and down, the dust bucket is arranged under the shell body, the cover plate is arranged above the shell body, a mixed flow chamber is formed among the shell body, the dust bucket and the partition plate, a flow collecting chamber is formed among the shell body, the cover plate and the partition plate, an inner barrel under the partition plate is arranged on the partition plate, an air feeding barrel vertically penetrating through the cover plate isarranged on the cover plate, the lower end of the air feeding barrel penetrates through the partition plate, a plurality of filter bags in the mixed flow chamber are arranged on the partition plate,the upper ends of the filter bags upwards penetrate through the partition plate and are connected with the partition plate, one side of each filter bag is arranged on the inner side of the inner barrel, the other side of each filter bag is arranged on the outer side of the inner barrel, a flow guiding hopper is arranged in the mixed flow chamber, an opening of the flow guiding hopper is downwardsarranged, the flow guiding hopper is arranged under the inner barrel, the flow guiding hopper and the inner barrel are coaxially arranged, an opening of the flow guiding hopper is connected with the dust bucket through a plurality of connection ribs, and an air outlet communicated with the flow collecting chamber is arranged on the shell body.

Owner:京鼎工程建设有限公司

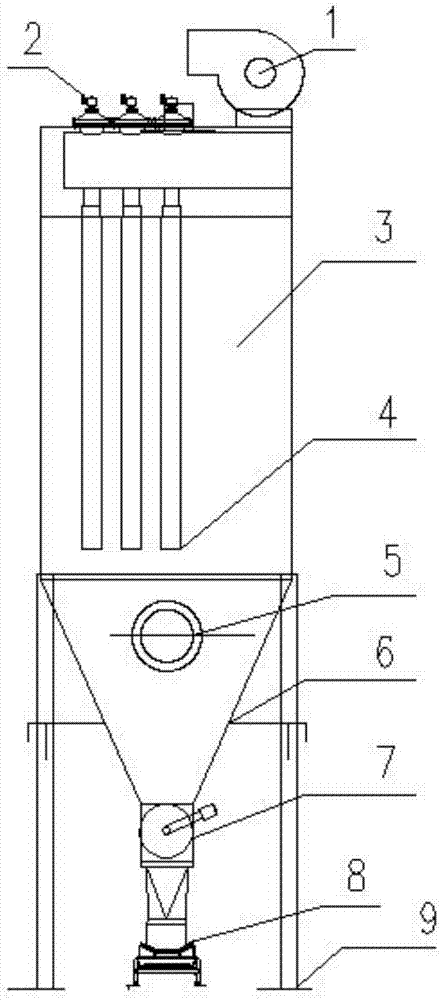

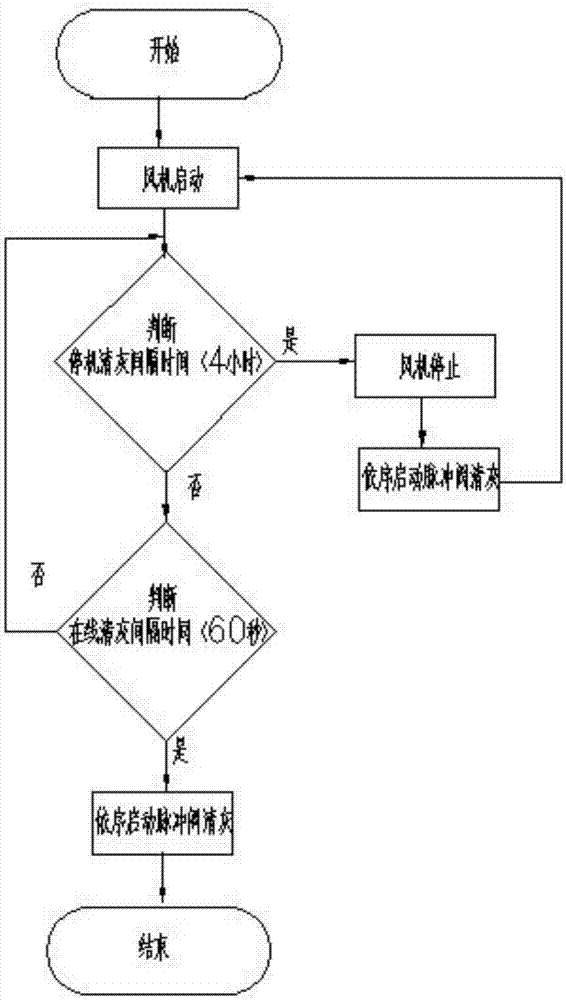

Control technology of heavy punch unloader type small pulsed jet cloth filter

InactiveCN107081018AImprove dust collection effectReduce resistanceDispersed particle filtrationBaghouseEngineering

The invention discloses a control technology of a heavy punch unloader type small pulsed jet cloth filter. The control technology comprises the following steps: at the beginning, starting a fan and starting a timer to time, and determining an interval time of cleaning dust; when the timer is less than 60 seconds, re-determining the interval time of cleaning the dust; when the timer is less than 4 hours and more than 60 seconds, starting an online dust cleaning procedure, and starting electromagnetic pulse-jet valves sequentially to clean dust; when the timer is greater than 4 hours, starting an off-line dust cleaning procedure, stopping the fan, starting the electromagnetic pulse-jet valves sequentially to clean dust, ending dust cleaning, starting the fan, and resetting the timer. According to the control technology of the heavy punch unloader type small pulsed jet cloth filter, the off-line dust cleaning procedure is added, through a mode of stopping of the fan, the dust cleaning operation on a filter bag module is realized, the service life of a filter bag is prolonged and the dust collecting effect of the jet cloth filter is improved.

Owner:HEFEI THERMOELECTRIC GRP CO LTD

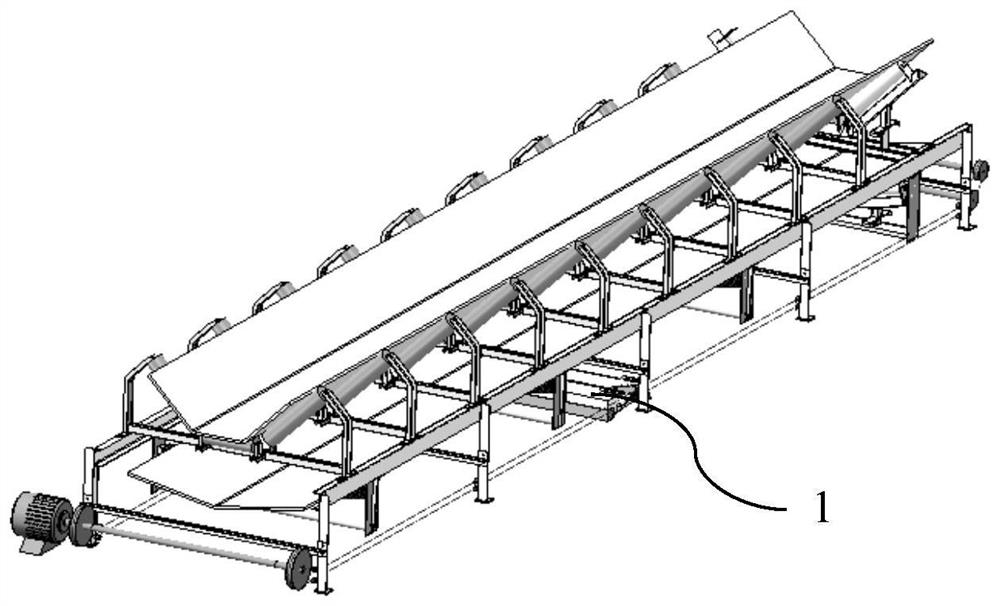

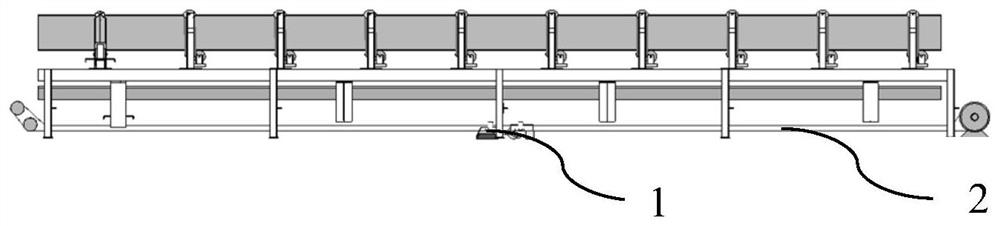

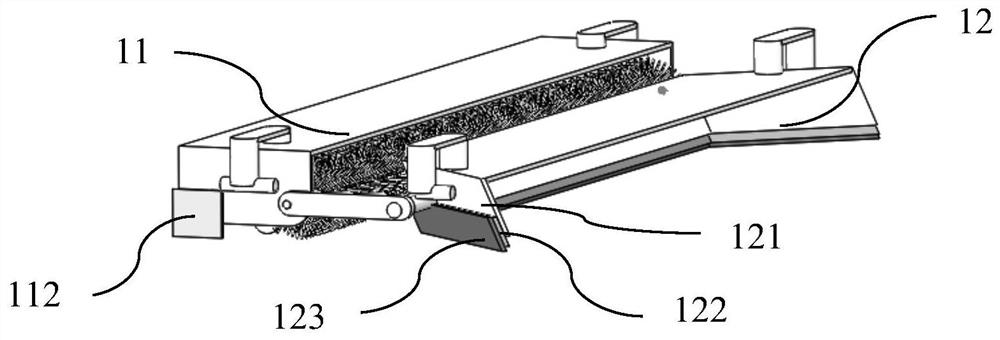

Coal conveying trestle ground water jet automatic cleaning device

PendingCN112693847AEasy to cleanRealize intelligent cleaningCleaningControl systemProcess engineering

The invention discloses a coal conveying trestle ground water jet automatic cleaning device which comprises a cleaning robot body, an inhaul cable power device and cleaning robot control system software, and is characterized in that the cleaning robot body is composed of a scraper device and a sweeping unit, and the cleaning robot body is installed on an inhaul cable and moves up and down through the inhaul cable. The inhaul cable power device adopts a double-cable circulation mode, the cleaning robot control system software is based on a network B / S framework, and the cleaning robot control system, an inspection robot control system, a flushing system and the like achieve system integration interaction and linkage control. When an inspection robot finds foreign matter in the inspection process, the cleaning robot can be controlled to execute a sweeping task, the cleaning robot can also automatically start the sweeping task by setting a timed cleaning task, and after sweeping, spraying and washing are automatically started to achieve all-around intelligent sweeping on the ground of a coal conveying belt.

Owner:苏州天河中电电力工程技术有限公司

Dust-proof device with dust removal structure for chip mounter

ActiveCN113289427ACleaning to achieveRealize cleaning operationDispersed particle filtrationTransportation and packagingDust controlStructural engineering

The invention provides a dust-proof device with a dust removal structure for a chip mounter, and relates to the technical field of chip mounters. A first support is fixedly arranged on a base, a top plate is fixedly arranged at the upper end of the first support, a flow conveying belt is fixedly arranged on the base, the first support is erected above the flow conveying belt, and side dust-proof nets are arranged on the front side and the rear side of the first support; end dustproof nets are arranged on the left side and the right side of the first support and erected above the flow conveying belt, side dust removal assemblies are symmetrically and fixedly arranged on the front side wall and the rear side wall of the first support, the side dustproof nets are arranged on the side dust removal assemblies, and the end dust removal assemblies are fixedly arranged on the base; equipment of different structures is adopted for dust removal for filter screens with different sections, the filter screens can be controlled to move, the dust removal equipment sweeps the surfaces of the filter screens, the dust removal function is achieved, the dust removal structure is arranged outside the machining interval of the equipment, it is guaranteed that dust removal and patch machining are separated, and the product yield is guaranteed.

Owner:常州冯卡斯登智能科技有限公司

Novel cup device

InactiveCN107252803AImprove work efficiencyRealize cleaning operationHollow article cleaningLiquid storage tankEngineering

The invention discloses a novel cup device which comprises a body and a liquid storage tank arranged at the top of the body. A liquid storage cavity is formed in the liquid storage tank, a conical cavity extending downwards and extending into the body is formed in the bottom of the liquid storage cavity in a through mode, a transfer cavity is formed in the liquid storage tank on the right side of the liquid storage cavity, a first conical wheel is arranged in the transfer cavity, a mixing shaft arranged to extend towards the left side is fixedly arranged at the left end of the first conical wheel, the extending section of the left side of the mixing shaft penetrates through the liquid storage tank between the transfer cavity and the liquid storage cavity and is connected in a wound and matched mode, the left-side lengthened tail of the mixing shaft extends into the liquid storage cavity and is in wound and matched connection with the inner wall of the left side of the liquid storage cavity, a first slide-conveying groove formed to extend towards the left side and the right side is formed in the bottom of the conical cavity in a through mode, a slide-conveying cavity is formed in the body below the first slide-conveying groove, and an infusion tube arranged to extend vertically is arranged in the body on the left side of the slide-conveying cavity. The novel cup device is simple in structure and convenient to operate, and the cleaning liquid utilization rate is improved.

Owner:YIWU PIKEYA IMPORT & EXPORT CO LTD

A multi-stage filter dust collector

The invention relates to a multi-stage filter dust collector, which comprises a shell, an ash hopper, a cover plate and a horizontal partition installed inside the shell, and the partition divides the inside of the shell into two parts that are not connected up and down. , the ash hopper is installed below the shell, the cover plate is installed above the shell, a mixed flow chamber is formed between the shell, the ash hopper and the partition, a collecting chamber is formed between the shell, the cover plate and the partition, and the shell There is an air inlet connected to the mixed flow chamber, and an air outlet connected to the collecting chamber on the shell; there is an inner cylinder placed vertically in the mixed flow chamber on the partition, and the inner cylinder is connected to the partition by rotation. The inner side of the inner cylinder forms a drainage chamber; the inner cylinder has a special-shaped filter bag with upper and lower openings placed under the inner cylinder. The vertical position of the special-shaped filter bag corresponds to the position of the air inlet. Booster fan; there are multiple vertically arranged microporous filter bags placed in the drainage chamber on the partition, and the upper end of the microporous filter bag penetrates upward through the partition and is connected with the partition.

Owner:XINYI HONGRUN QUARTZ SILICA POWDER

Scotching device for towel or bath towel processing

ActiveCN113151939ARealize cleaning operationImprove processing efficiencyFibre cleaning/opening machinesProcess engineeringYarn

The invention discloses a scutching device for towel or bath towel processing, and relates to the technical field of textile fabric processing. The scutching device comprises a processing box; the processing box comprises a first chamber and a second chamber arranged below the first chamber; a feeding hole is formed in the top wall of the first chamber; the lower part of the first chamber communicates with the upper part of the second chamber; a cotton opening assembly is arranged in the first chamber; and a vibration screen assembly is arranged in the first chamber. Cotton yarns are separated in a rolling mode through the cotton opening assembly, the separated cotton yarns are screened in a rotary vibration mode through the vibration screen assembly, the structural design is reasonable, use is convenient and fast, the cotton yarn treatment efficiency is effectively improved, and relatively high market application value is achieved.

Owner:安徽省伊贝雅纺织有限公司

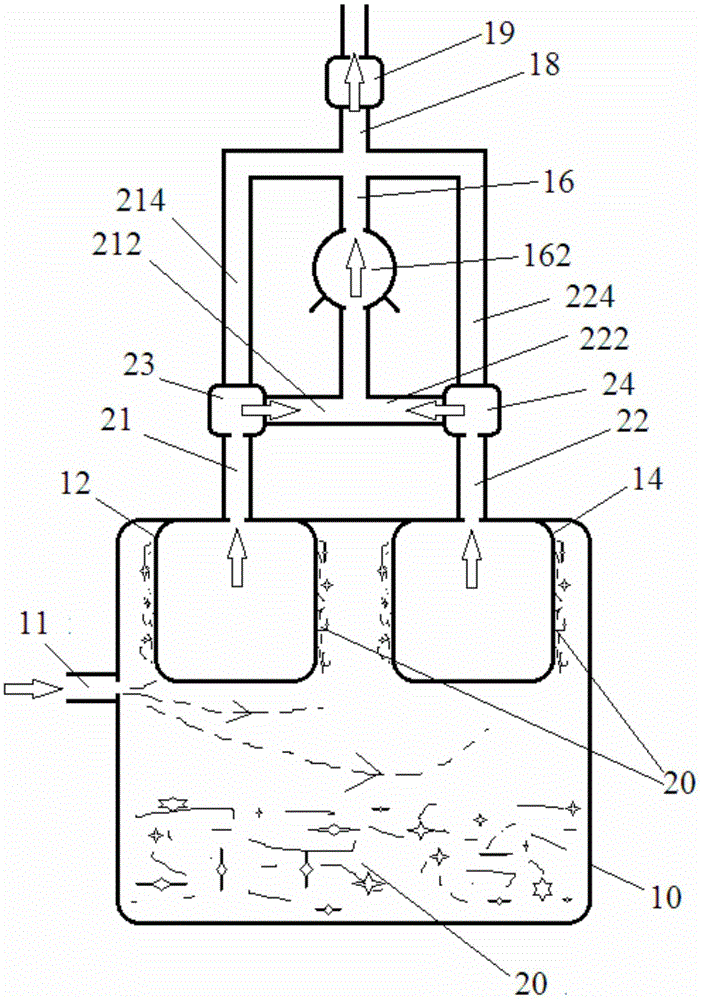

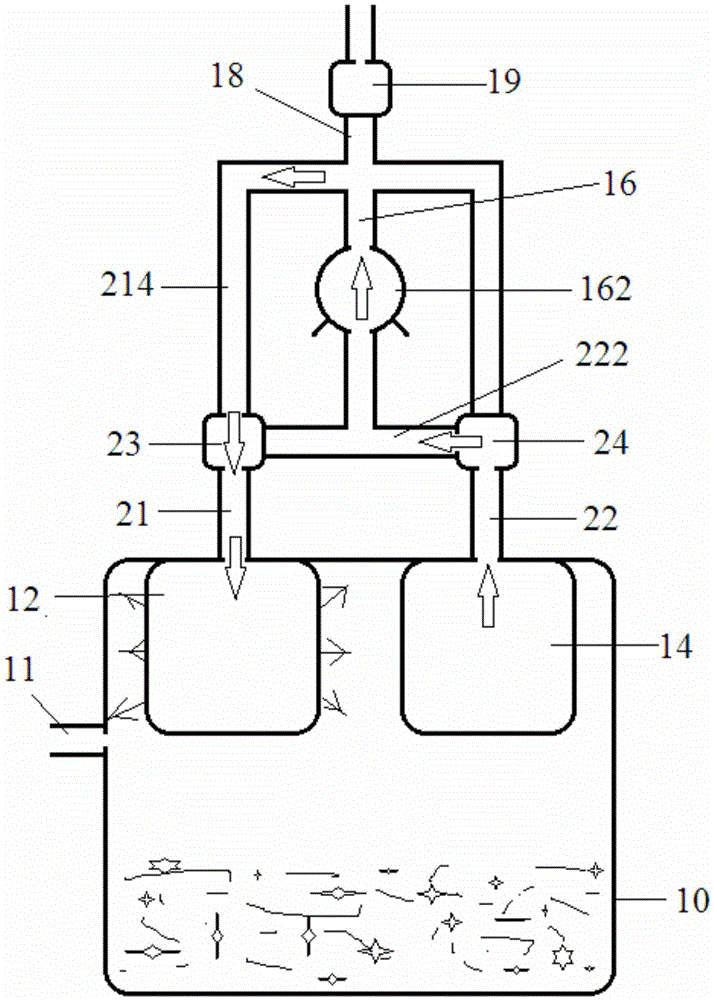

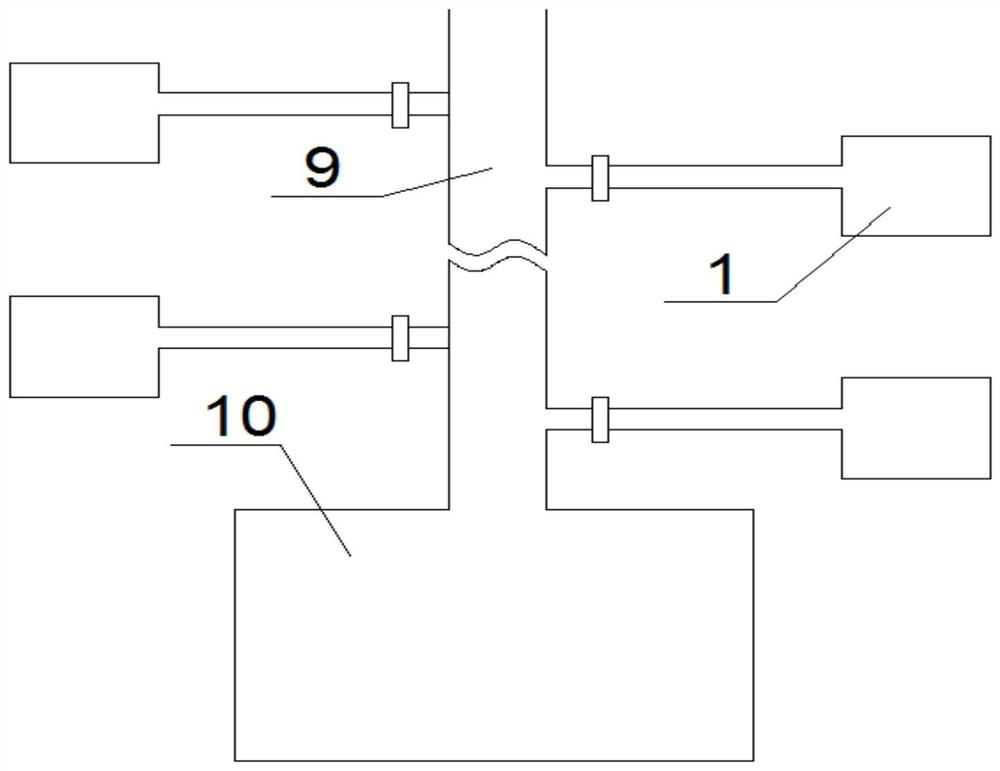

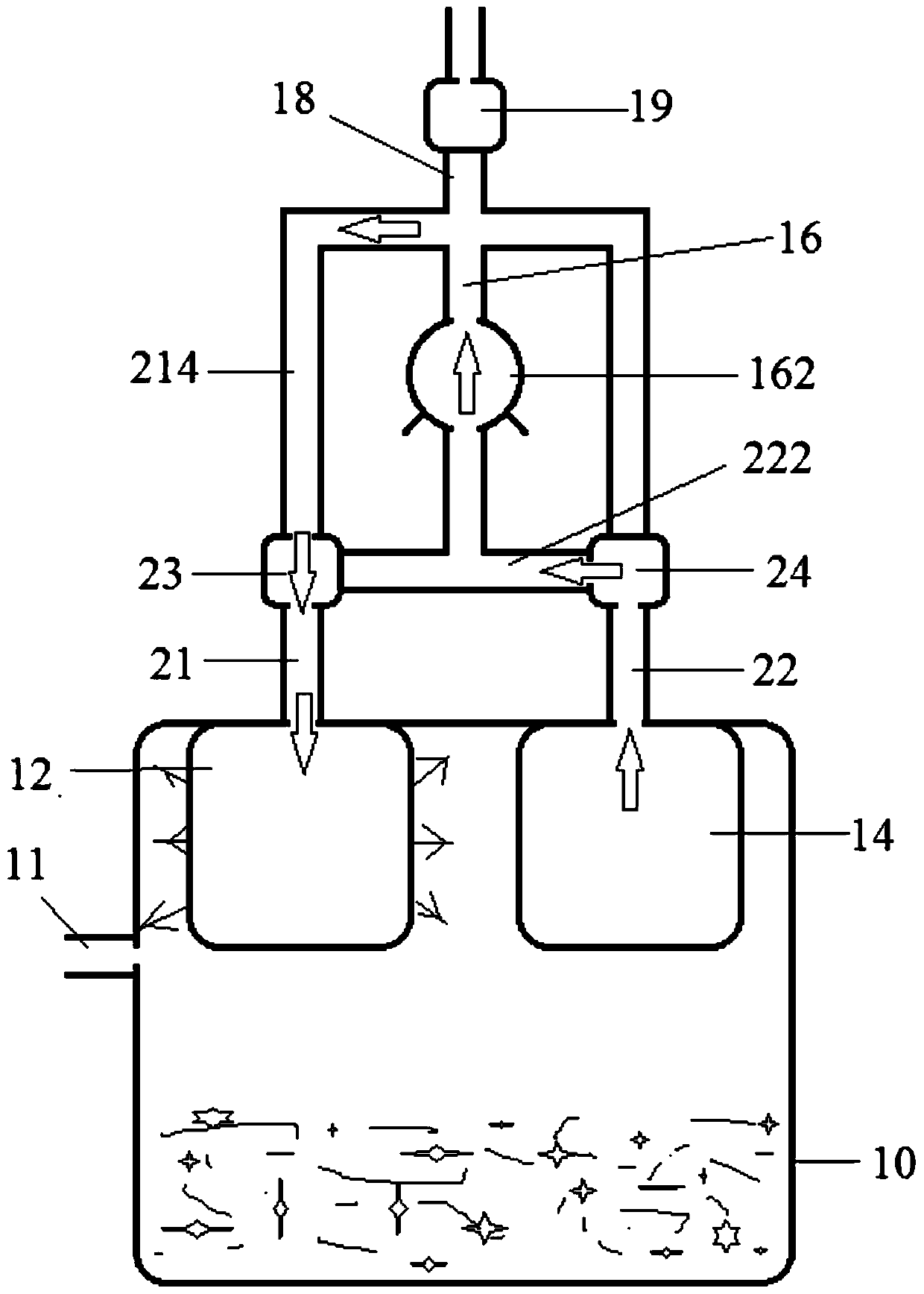

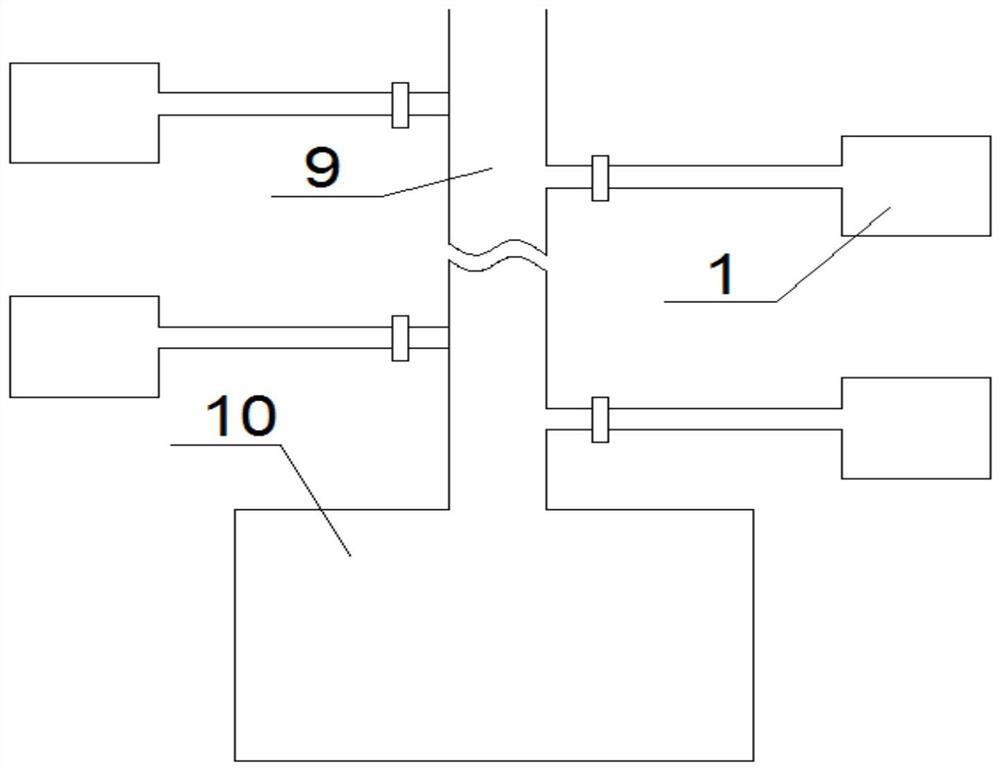

Back-blow dedusting system

ActiveCN105597439ARealize cleaning operationNo outflow lossGas treatmentDispersed particle filtrationEngineeringMechanical engineering

The invention provides a back-blow dedusting system. The back-blow dedusting system comprises a first passage, a second passage and an exhaust passage, wherein one end of the first passage and one end of the second passage are used for being connected with a first filtering device and a second filtering device respectively. A first valve and a second valve are arranged on the first passage and the second passage respectively. By the aid of the first valve and the second valve, the first passage is communicated with the second passage, or the first passage and the second passage are communicated with the exhaust passage.

Owner:南通鑫萍复合材料科技有限公司

A radiation-resistant pipeline laser cleaning device and its application method

ActiveCN112827946BImprove flexibilityRealize cleaning operationHollow article cleaningDirt cleaningBeam expanderDose rate

The application provides a radiation-resistant pipe laser cleaning device, which includes a laser transmission mechanism, a fixed support, a movement mechanism, a guiding dust suction device and a cleaning mechanism. The emission side of the laser transmission mechanism runs through the movement mechanism and the guiding dust suction device in sequence The cleaning mechanism is connected; the guiding dust collection device includes a vacuum cleaning device, a guide wheel mechanism and bolts. A beam expander, a plane mirror, a vibrating mirror unit and a focusing device, the plane mirror is arranged directly in front of the beam expander and connected to the inner wall of the cleaning mechanism. In this application, the cleaning mechanism rotates and feeds at the same time through the action of the movement mechanism, so that the beam focused on the inner wall of the pipeline to be cleaned does a spiral movement, which overcomes the cleaning environment that cannot adapt to the high radiation dose rate; the first support rod and the two supports in the movement unit The end faces between the plates are hinged and have good flexibility.

Owner:HUNAN UNIV

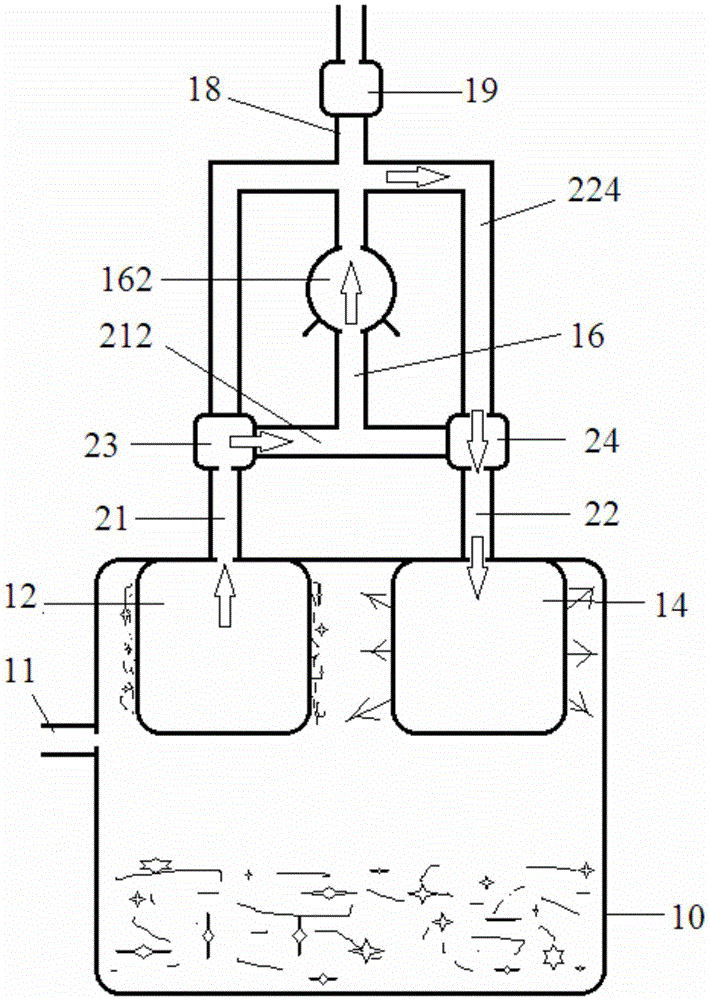

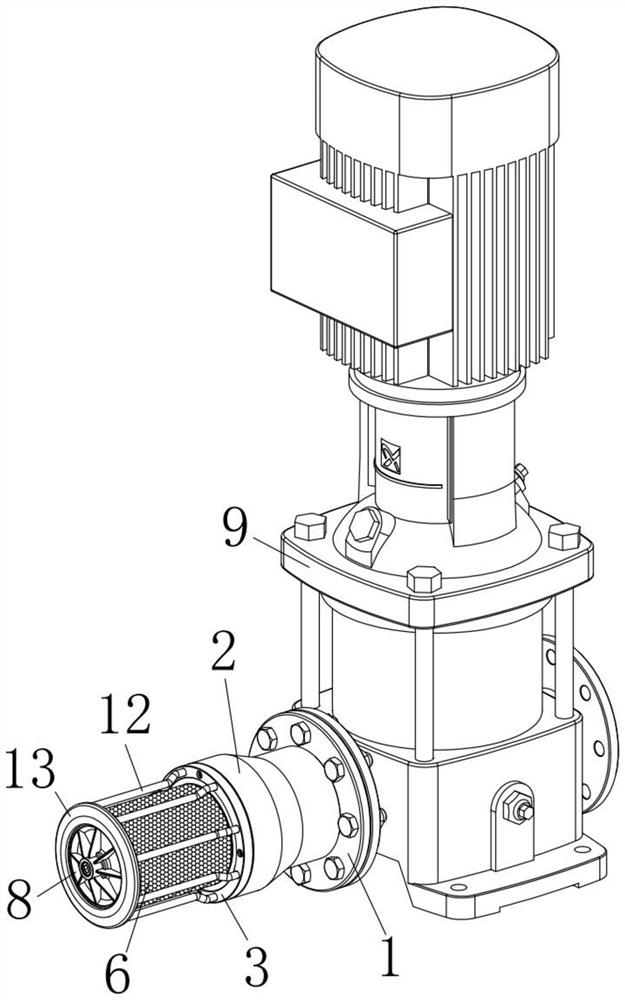

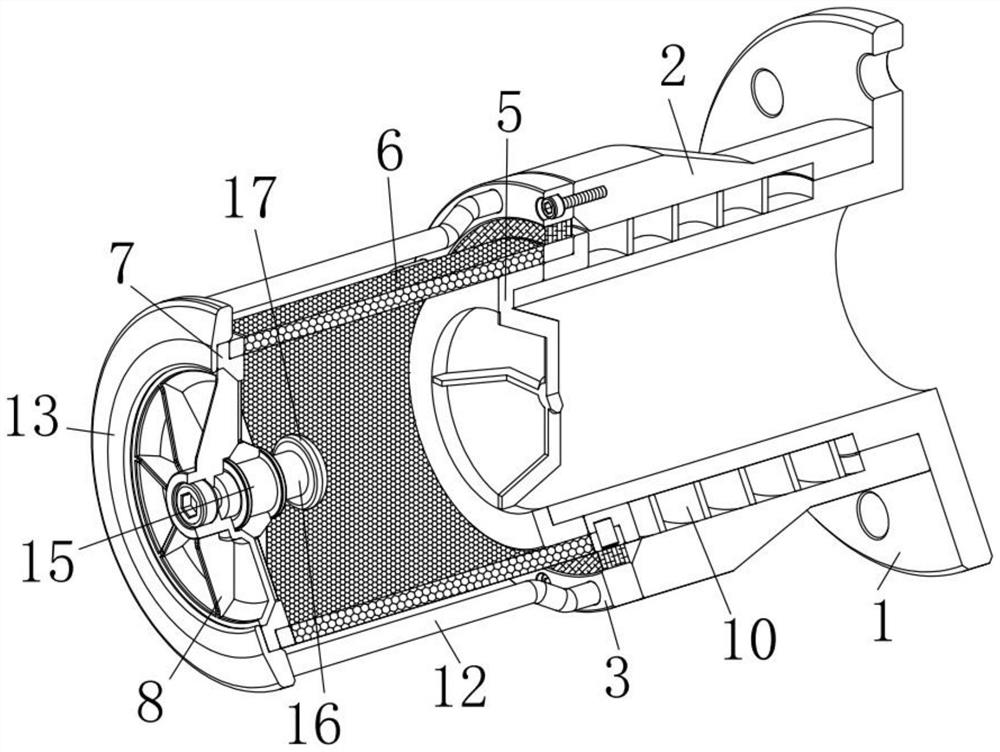

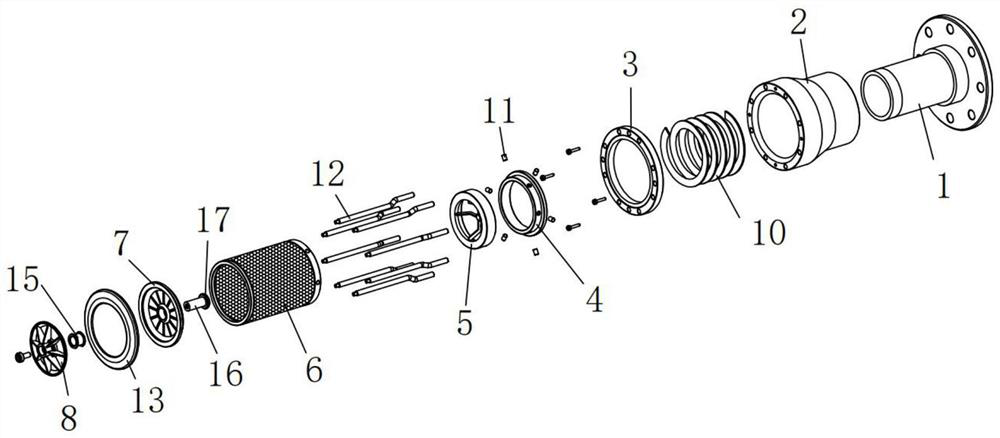

Agricultural irrigation water pump with decontamination and anti-blocking functions

ActiveCN113251005AWith cleaning and anti-blocking functionRealize resetPump componentsPumpsWater useAgricultural irrigation

The invention disclose an agricultural irrigation water pump with decontamination and anti-blocking functions. The water pump is characterized in that a connecting base is arranged at a water inlet of a pump body, the connecting base is connected with a water inlet flange of the pump body, a limiting mechanism is arranged at the end, away from the water inlet of the pump body, of the connecting base, the other end of a sliding rod is connected with a second end cover in a sleeved mode, the sliding rod is in bolted connection with the second end cover, a plurality of third connecting holes are fixedly connected with one ends of a plurality of connecting rods, and the other ends of the plurality of connecting rods penetrate through a decontamination brush to be fixedly connected with a shell. According to the agricultural irrigation water pump with the decontamination and anti-blocking functions, irrigation water is filtered by means of a filter sleeve, and when the outer wall of the filter sleeve is blocked by accumulated dirt, water pressure can push the second end cover and a first end cover to move towards the water inlet, so that the outer wall of the filter sleeve makes contact with the decontamination brush, decontamination operation on the surface of the filter sleeve is achieved, pressure stabilization is realized through the cooperation of the limiting mechanism, the first end cover, the second end cover, the connecting rods and a push block, and finally resetting of the filter sleeve is realized under action of a disc spring.

Owner:山东云之雨精密模具有限公司

A bag filter

ActiveCN108854295BRealize cleaning operationSimple and fast cleaning operationCombination devicesDispersed particle filtrationMixed flowStructural engineering

The invention relates to a new type of bag dust collector, which includes a shell, an ash hopper, a cover plate and a horizontal partition installed inside the shell. The partition divides the inside of the shell into two parts that are not connected up and down. The ash hopper is installed below the shell, and the cover plate is installed above the shell. A mixing chamber is formed between the shell, the ash hopper and the partition, and a collecting chamber is formed between the shell, the cover plate and the partition; There is an inner cylinder placed under the partition, and the cover plate has an air inlet tube vertically penetrating through the cover plate, and the lower end of the air inlet tube penetrates the partition board; there are multiple filter bags placed in the mixed flow chamber on the partition board, and the filter bag The upper end goes through the partition upwards and is connected with the partition. One side of the filter bag is placed inside the inner cylinder, and the other side of the filter bag is placed outside the inner cylinder; there is a diversion bucket with the opening facing downward in the mixed flow chamber, and the diversion bucket is placed It is arranged under the inner cylinder and is coaxial with the inner cylinder. The opening of the diversion bucket is connected with the ash bucket through a plurality of connecting ribs; there is an air outlet connected with the collecting chamber on the shell.

Owner:京鼎工程建设有限公司

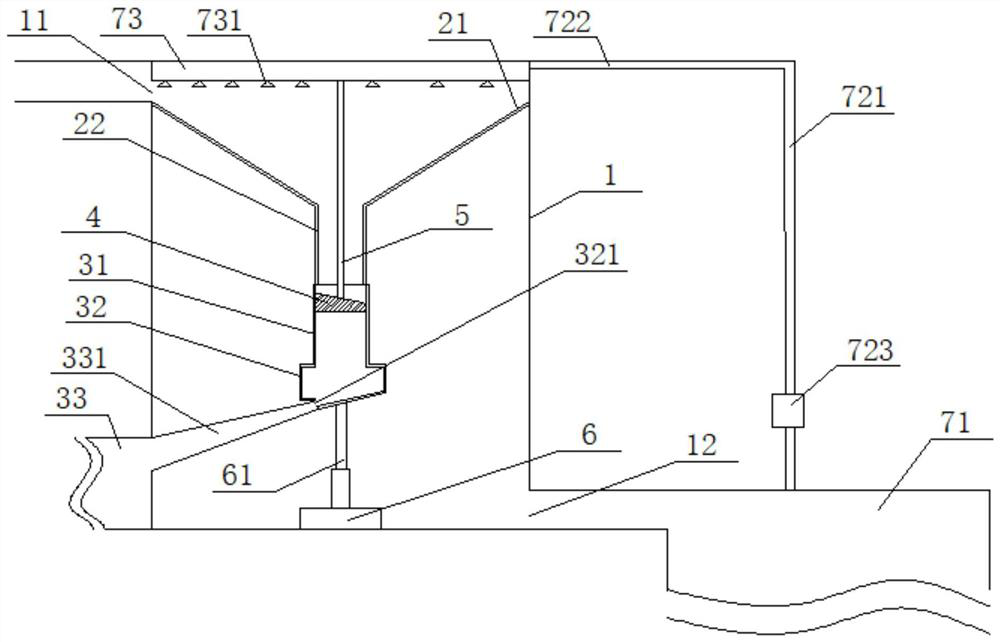

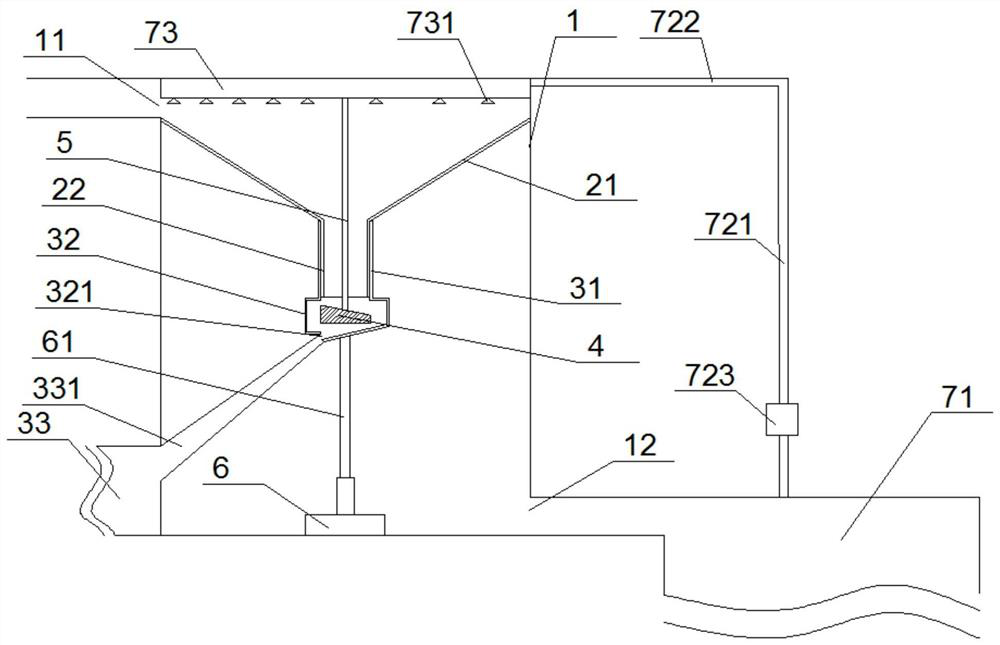

Air side drainage system and construction method thereof

ActiveCN112196053AGuaranteed continuous operationImprove water resource utilizationFatty/oily/floating substances removal devicesSewerage structuresHydraulic cylinderWater use

The invention discloses an air side drainage system. The air side drainage system comprises a drainage ditch and a plurality of collecting devices, and any collecting device comprises a filter box, afilter pipe, a blow-off pipe set, a sealing plug, a connecting rod, a telescopic hydraulic cylinder and a cleaning mechanism; and a plurality of spraying devices are arranged on air side lawn, each collecting device is provided with the corresponding spraying device, and a water inlet of each spraying device communicates with a corresponding collecting chamber. The multiple collecting devices arearranged below the air side lawn at intervals, thus water in the drainage ditch can be filtered, decontaminated, collected and recycled, and the water resource utilization rate is increased; the collected water can be used for irrigating the lawn, and the water in the collecting chambers can be further used for other water needs of airports; and meanwhile, in the filtering and decontaminating processes, dirt obtained through filtering can be further automatically cleared and collected at regular intervals, the collecting devices do not need to be manually disassembled for decontaminating clearing of the filter pipe, and continuous and normal operation of filtering, decontaminating, collecting and recycling of the water in the drainage ditch is guaranteed.

Owner:CHINA HARBOUR ENGINEERING

A dust-proof device for a placement machine with a dust-cleaning structure

ActiveCN113289427BCleaning to achieveRealize cleaning operationDispersed particle filtrationTransportation and packagingDust controlEngineering

A dust-proof device for a chip mounter with a dust cleaning structure, the invention relates to the technical field of chip mounters. A No. 1 bracket is fixedly arranged on a base, a top plate is fixedly arranged on the upper end of the No. 1 bracket, and a flowing water conveyor belt is fixedly arranged on the base. The No. 1 bracket is erected above the flowing water conveyor belt. The front and rear sides of the No. 1 bracket are provided with side dustproof nets, and the left and right sides of the No. 1 bracket are provided with end dustproof nets. Above the belt, side dust removal components are symmetrically fixed on the front and rear side walls of the No. 1 bracket, and the side dust removal screen is set on the side dust removal component, and the end dust removal component is fixed on the base; it is suitable for filters of different sections. , Use different structural equipment for dust removal, which can control the movement of the filter screen, and make the dust removal equipment sweep the surface of the filter screen to realize the dust removal function, and the dust removal structure is set outside the processing area of the equipment to ensure the separation of dust removal and patch processing, and ensure the product Yield rate.

Owner:常州冯卡斯登智能科技有限公司

Convenient cup device

InactiveCN108236438AImprove work efficiencySimple structureTableware washing/rinsing machine detailsEngineeringConical cavity

The invention discloses a convenient cup device which comprises a main body and a liquid storage box arranged at the top of the main body, wherein a liquid storage cavity is formed in the liquid storage box; the bottom of the liquid storage cavity is communicated with a conical cavity extending downward into the main body; a transfer cavity is arranged in the liquid storage box on the right side of the liquid storage cavity; a first conical wheel is arranged in the transfer cavity; a mixing shaft extending toward the left side is fixed at the left end of the first conical wheel; the left sideextension section of the mixing shaft penetrates through the liquid storage box between the transfer cavity and the liquid storage cavity, and is in rotary fit connection; the left side extension tailof the mixing shaft stretches into the liquid storage cavity and is in rotary fit connection with the left side inner wall of the liquid storage cavity; the bottom of the conical cavity is communicated with a first sliding slot extending toward the left and right sides; a sliding cavity is formed in the main body below the first sliding slot; and a liquid pipe extending up and down is arranged inthe main body on the left side of the sliding cavity. The convenient cup device disclosed by the invention has the advantages of simple structure and convenience in operation, and improvement of theutilization rate of cleaning liquid.

Owner:方新刚

A back blowing dust removal system

ActiveCN105597439BRealize cleaning operationNo outflow lossGas treatmentDispersed particle filtrationEngineering

The present invention provides a back blowing dust cleaning system, which includes a first channel, a second channel, and an exhaust channel, and one end of the first channel and the second channel is respectively used to connect the first filter device and the second filter device . Wherein the first channel and the second channel are respectively provided with a first valve and a second valve, and by setting the first valve and the second valve, the communication between the first channel and the second channel is made, Or make the first channel communicate with the second channel and the exhaust channel.

Owner:南通鑫萍复合材料科技有限公司

Cotton cleaning device for towel or bath towel processing

ActiveCN113151939BRealize cleaning operationImprove processing efficiencyFibre cleaning/opening machinesYarnProcess engineering

The invention discloses a cotton cleaning device for processing towels or bath towels, and relates to the technical field of textile processing. The invention includes a processing box; the processing box includes a first chamber and a second chamber arranged below the first chamber; the top wall of the first chamber is provided with a feed port; the lower part of the first chamber and the second chamber The upper part of the chamber is connected; the cotton opening assembly is installed in the first chamber; the vibrating screen assembly is installed in the first chamber. In the present invention, the cotton yarn is separated by rolling through the cotton opening assembly, and the separated cotton yarn is screened by rotary vibration by the vibrating screen assembly, which not only has a reasonable structure design and is convenient to use, but also effectively improves the processing efficiency of the cotton yarn. High market application value.

Owner:安徽省伊贝雅纺织股份有限公司

Airside drainage system and its construction method

ActiveCN112196053BGuaranteed continuous operationImprove water resource utilizationFatty/oily/floating substances removal devicesSewerage structuresWater useHydraulic cylinder

The invention discloses an airside drainage system, which comprises: a drainage ditch and a plurality of collection devices, any collection device includes a filter box, a filter pipe, a sewage pipe group, a sealing plug, a connecting rod, a telescopic hydraulic cylinder, and a cleaning mechanism Wherein, a plurality of spraying devices are arranged on the airside lawn, and a collecting device is correspondingly provided with a spraying device, and the water inlet of each spraying device communicates with the corresponding collecting chamber. The present invention can filter and decontaminate the water in the drainage ditch by arranging a plurality of collecting devices at intervals under the lawn on the empty side, collect and reuse, and improve the utilization rate of water resources; the collected water can be used for lawn irrigation, and the collected water can also be used The water in the room is used for other water needs of the airport; at the same time, in the process of filtering and decontaminating, the filtered dirt can also be cleaned and collected automatically on a regular basis, without manual disassembly of the collection device to decontaminate and clean the filter tube, ensuring It is a continuous normal operation of filtering, decontaminating, collecting and reusing the water in the drainage ditch.

Owner:CHINA HARBOUR ENGINEERING

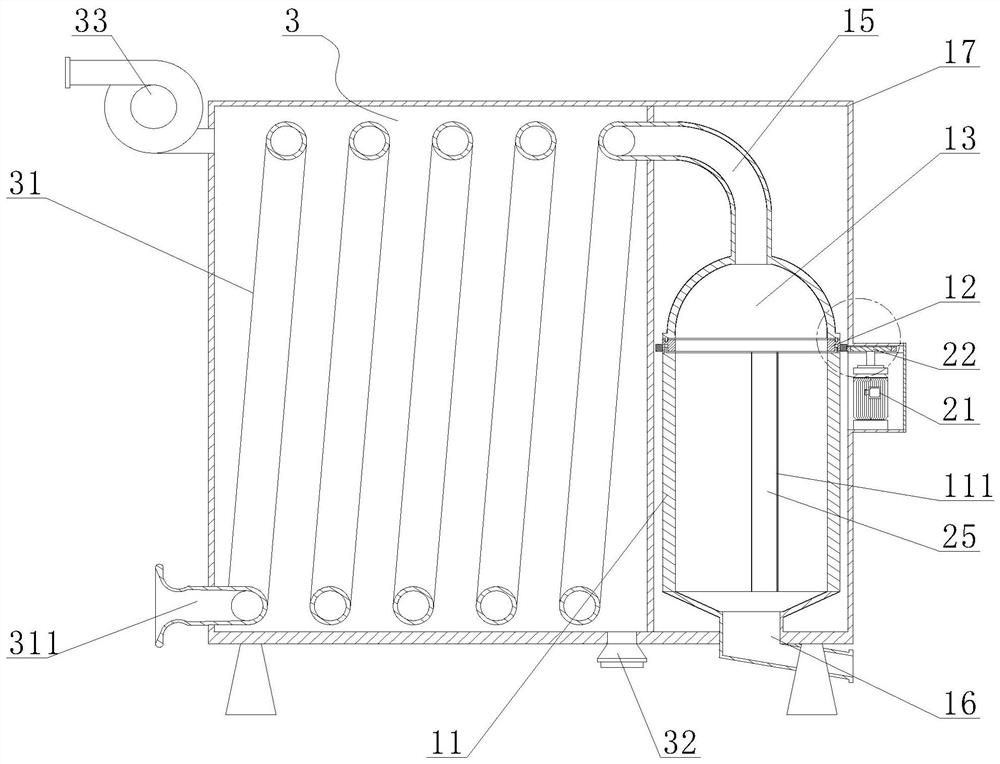

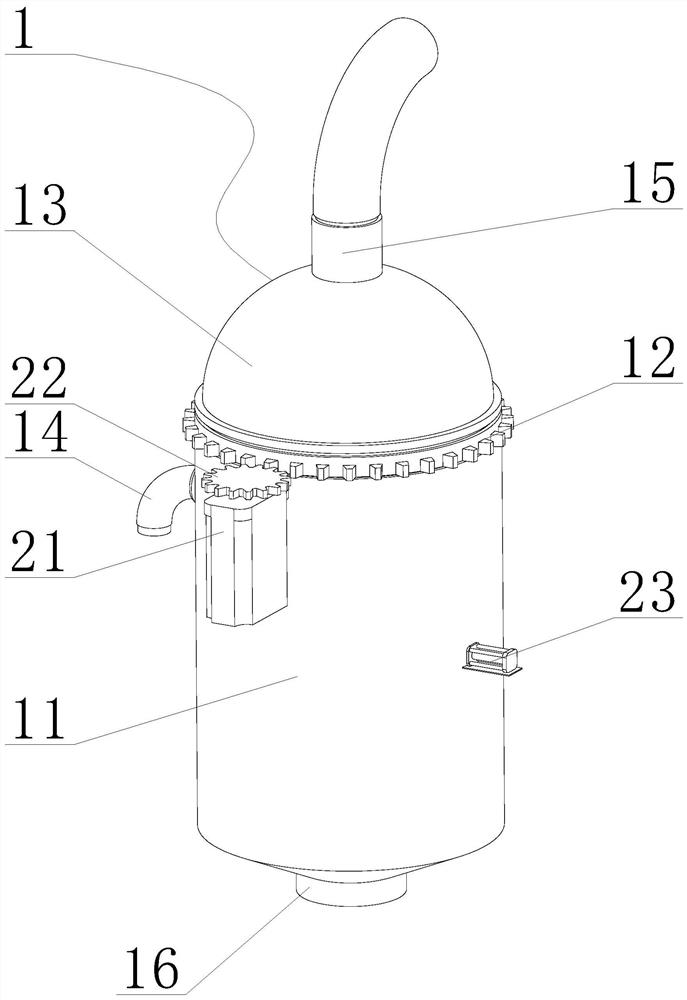

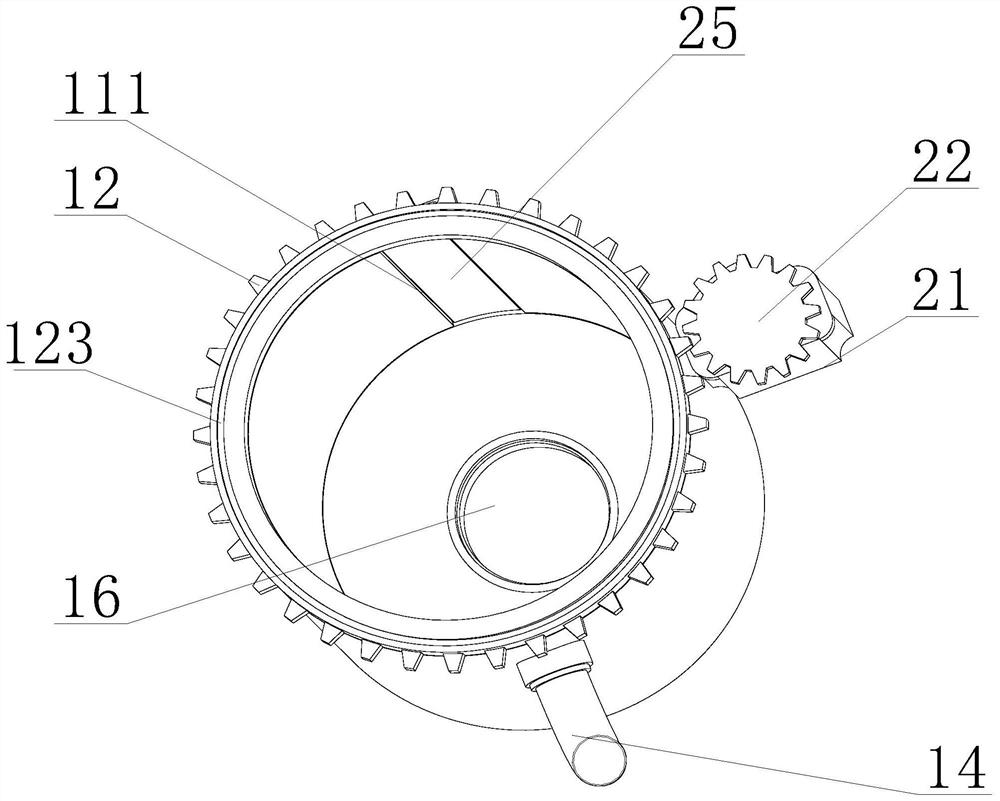

A hot blast stove with automatic dust removal

ActiveCN112013541BRealize cleaning operationAvoid interferenceAir heatersCombustion technology mitigationHydraulic cylinderHot air oven

The invention relates to a hot air stove for automatic dust removal, which includes a shell, a combustion furnace and a heat exchanger connected with the combustion furnace. The combustion furnace is provided with a dust removal assembly that can rotate to shovel the inner wall of the combustion furnace. The combustion furnace A shovel knife for shoveling ash is accommodated in the furnace wall, and the hydraulic cylinder in the ash cleaning assembly pushes the shovel knife out of the furnace wall and is driven by the rotating ring in the upper combustion furnace to rotate along the furnace wall to achieve ash shoveling. The invention accommodates and protects the shovel by setting up a storage cavity and a sliding door on the inner wall of the combustion furnace, so as to prevent the shovel from interfering with the combustion of the fuel inside the combustion furnace or being damaged by the long-term heating of the combustion furnace. The motor drives the gear, and the gear passes through the The gear teeth on the outer wall of the rotating ring drive the rotating ring to rotate, and the rotating ring drives the shovel pushed out of the storage chamber by the hydraulic cylinder through the card slot, and performs a circular rotation on the inner wall of the furnace to realize the cleaning operation of the inner wall of the furnace, which is automatic The cleaning avoids manual troubles.

Owner:无为皖江粮食机械有限公司

Efficient water cup device

InactiveCN107297368AImprove work efficiencySimple structureHollow article cleaningConical cavityUtilization rate

The invention discloses an efficient water cup device which comprises a body and a fluid storage tank. The fluid storage tank is arranged on the top of the body, a fluid storage cavity is arranged in the fluid storage tank, a conical cavity which downwardly extends and extends into the body is arranged at the bottom of the fluid storage cavity in a communicated manner, a transfer cavity is arranged in the fluid storage tank and is positioned on the right side of the fluid storage cavity, a first conical wheel is arranged in the transfer cavity, a mixing shaft which extends towards the left side is fixedly arranged at the left end of the first conical wheel, an extension section on the left side of the mixing shaft penetrates the portion, which is positioned between the transfer cavity and the fluid storage cavity, of the fluid storage tank and is fittingly connected with the portion in a wound manner, an extension tail end on the left side of the mixing shaft extends into the fluid storage cavity and is fittingly connected with the inner wall of the left side of the fluid storage cavity in a wound manner, a first slide groove which extends towards the left side and the right side is formed in the bottom of the conical cavity in a communicated manner, a slide cavity is arranged in the body and is positioned below the first slide groove, and a fluid delivery pipe which extends in the up-down directions is arranged in the body and is positioned on the left side of the slide cavity. The efficient water cup device has the advantages that the efficient water cup device is simple in structure and convenient to operate, and the utilization rate of cleaning fluid can be increased.

Owner:YIWU PIKEYA IMPORT & EXPORT CO LTD

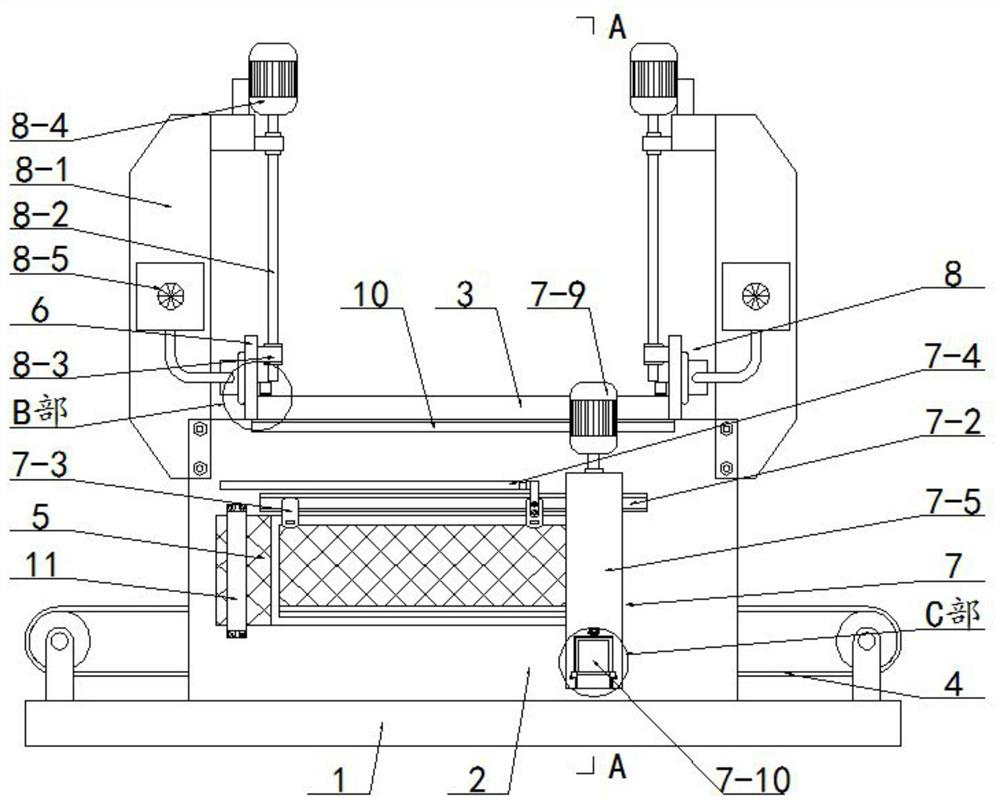

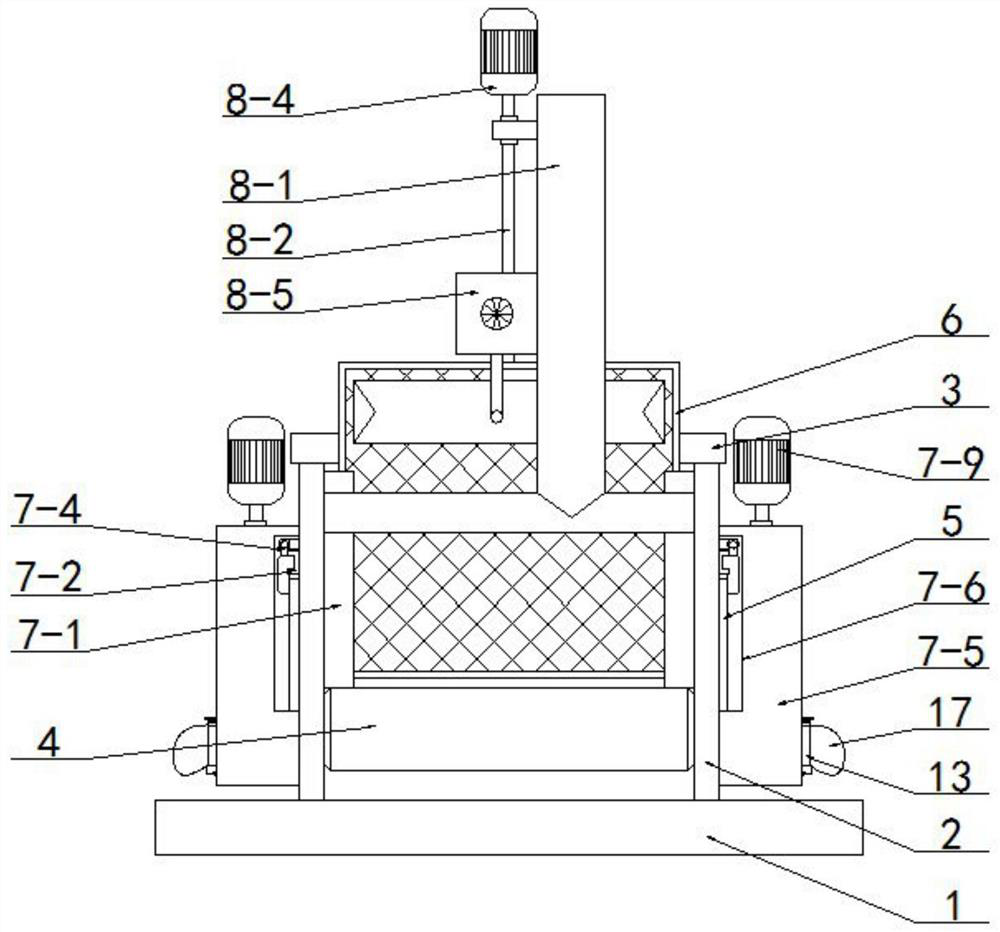

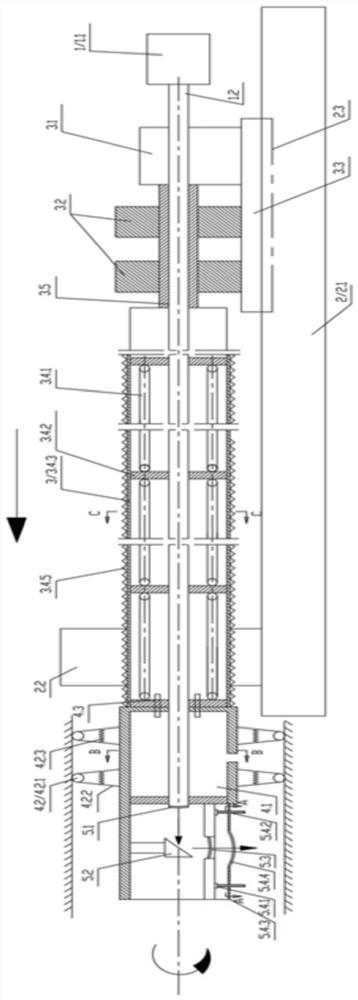

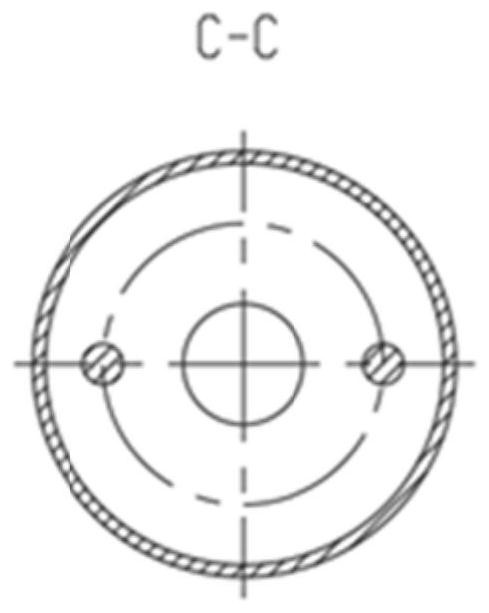

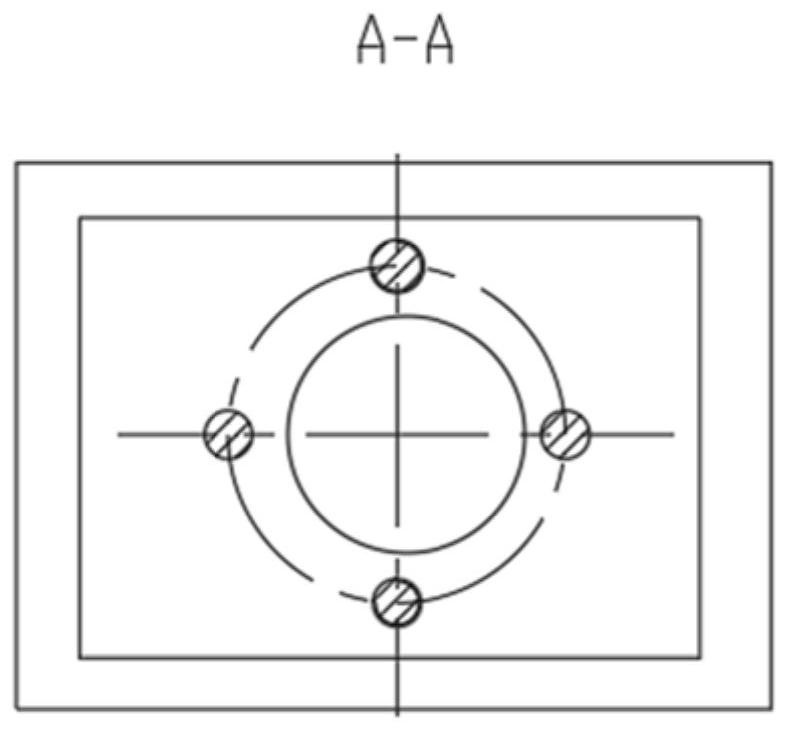

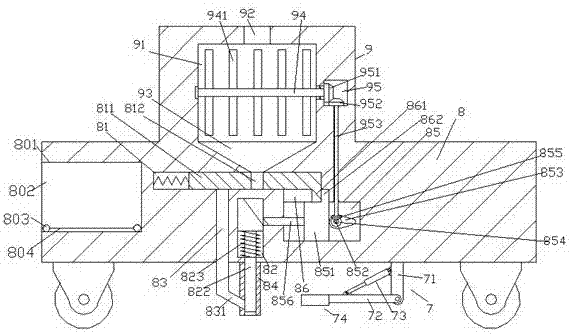

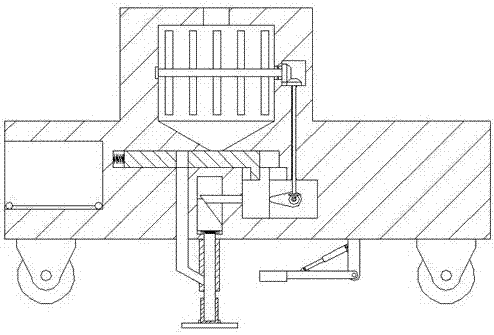

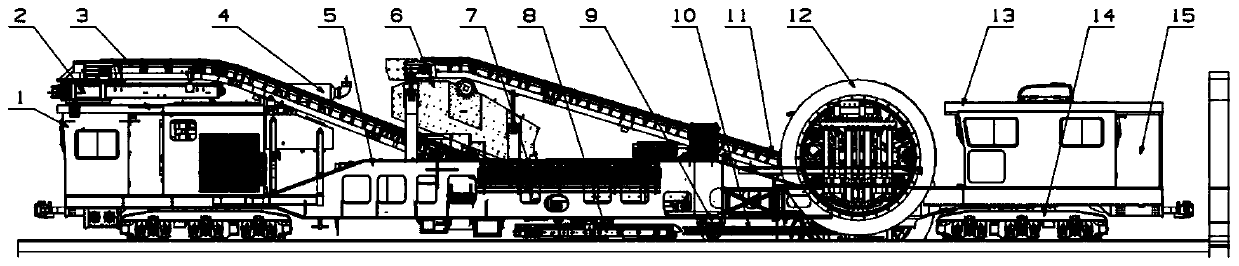

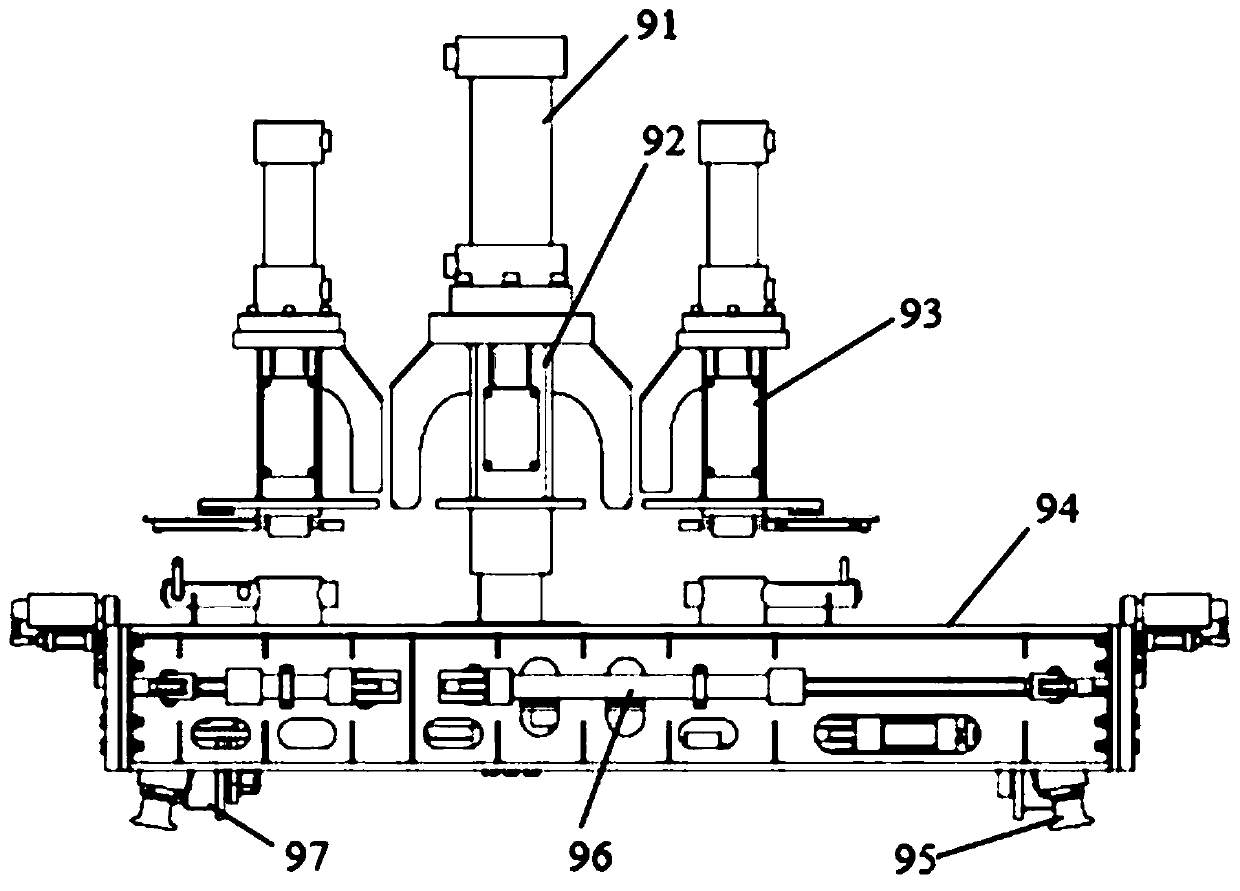

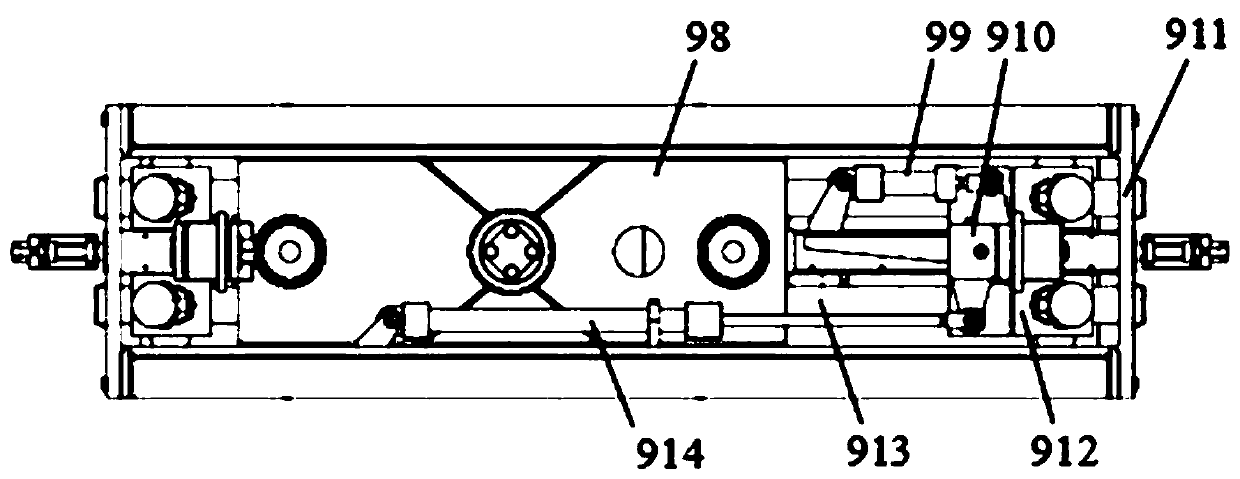

Screen scarifier for continuous track lifting operation in turnout zone, and operation method thereof

PendingCN110983878ARealize cleaning operationLabor savingBallastwayControl engineeringControl theory

The invention provides a screen scarifier for continuous track lifting operation in a turnout zone, and an operation method thereof. The screen scarifier comprises a vehicle body and a continuous track lifting device, and the continuous track lifting device is installed below the vehicle body and located between a backfill conveying belt and an excavating device. The screen scarifier for continuous track lifting operation in the turnout zone, and the operation method thereof are provided to solve the problems that a turnout zone track panel sinks integrally, ballast bed stone ballast backfillis not ideal and the like after turnout screen scarifying operation due to the fact that an existing screen scarifier does not have a corresponding turnout zone track lifting device in the turnout zone.

Owner:CRCC HIGH TECH EQUIP CORP LTD

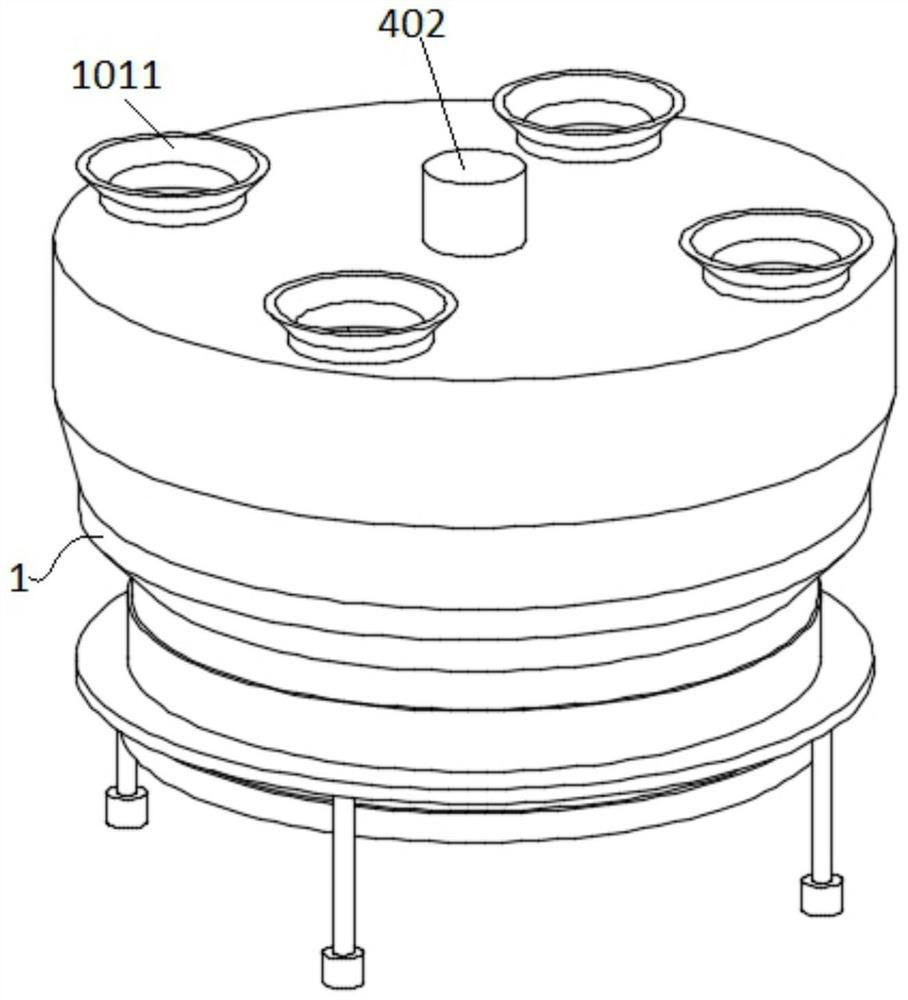

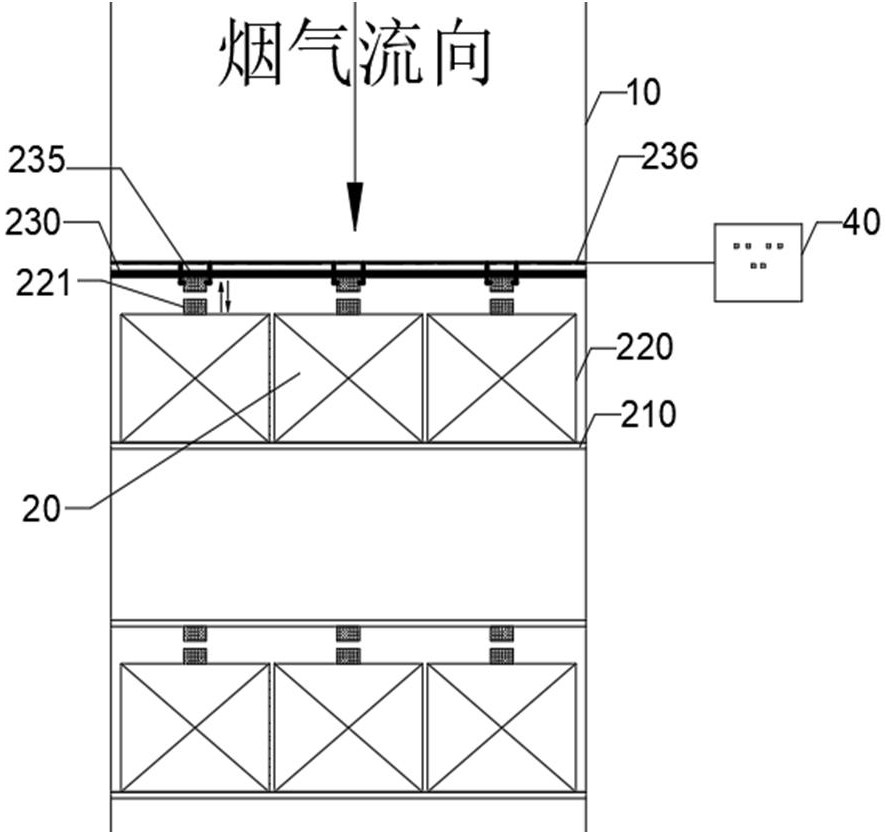

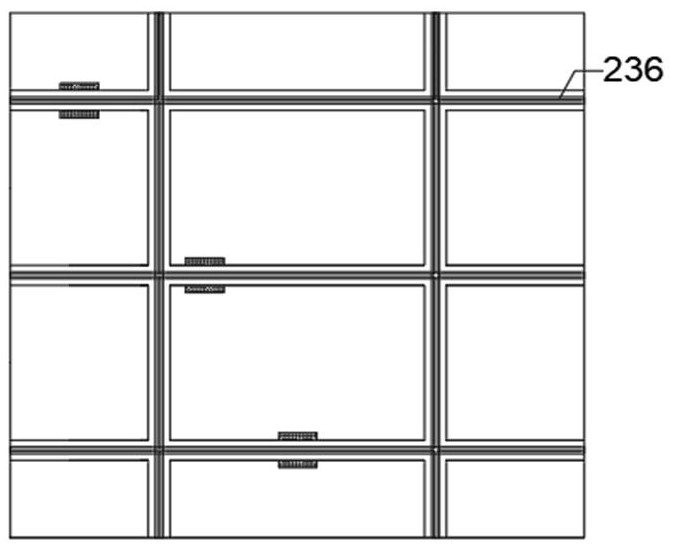

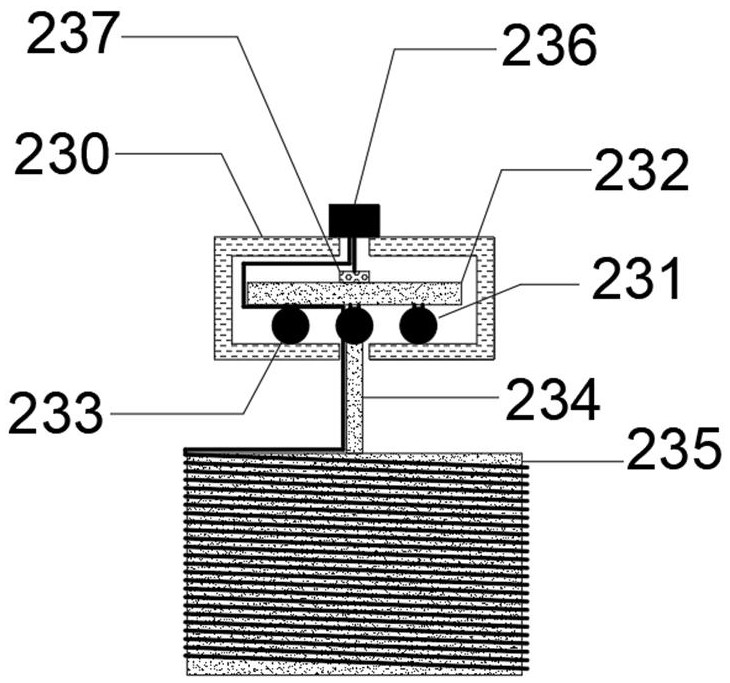

Denitration reactor hoisted by magnetic force

ActiveCN112742208AIncrease heightLower the altitudeGas treatmentDispersed particle separationThermodynamicsPtru catalyst

The invention discloses a denitration reactor. The reactor comprises a reactor shell and a plurality of catalyst bed layers, each catalyst bed layer comprises a supporting beam, a catalyst module and a magnetic hoisting beam; more than one catalyst mounting door is arranged at the position, corresponding to each catalyst bed layer, of the reactor shell; the projection center line of the catalyst hoisting beam in the vertical direction penetrates through the center point of each catalyst module, and the hoisting beam is communicated with the catalyst mounting door of the layer; and the plurality of hoisting trolleys are arranged below the hoisting beam, electromagnetic modules are arranged at the lower parts of the hoisting trolleys, a magnet is arranged at the center above each catalyst module, and the electromagnetic modules are in one-to-one correspondence with the magnets on the catalyst modules below the electromagnetic modules. According to the denitration reactor, automatic installation of the catalyst module can be achieved, and meanwhile automatic ash removal operation of the denitration module can be achieved. The denitration reactor provided by the invention can reduce the height of the reactor or increase the filling amount of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel hardcover grinding machine

PendingCN111941263AElegant appearanceRealize cleaning operationGrinding drivesLapping machinesDust controlEngineering

The invention provides a novel hardcover grinding machine. The novel hardcover grinding machine comprises a grinding machine main body, wherein a pushing and pressing mechanism, a grinding mechanism and a dust removal system are arranged in the grinding machine main body; the pushing and pressing mechanism comprises a pressing assembly; the pressing assembly comprises a front pressing plate, a rear baffle and a title page pressing plate; the front side of the front pressing plate is connected with a pressing cylinder; linear rails are arranged on the two sides of the pressing assembly; two sliding blocks are mounted on the linear rails; a reset cylinder is arranged on the left side of the title page pressing plate; a front-back displacement cylinder is arranged on the rear side of the pressing assembly; the grinding mechanism comprises an expansion shaft; the expansion shaft is sleeved with an abrasive paper sleeve; a brush roller is arranged on the rear side of the expansion shaft; the dust removal system comprises a dust removal box; and the rear side of the dust removal box is connected with a dust suction interface. The novel hardcover grinding machine has the beneficial effects that the whole machine is of an all-steel-plate welding structure, is of a combined box type integrated structure, has high rigidity and stability, runs quietly, adopts a fully-closed protective cover, and is attractive in appearance and small in occupied area; and a brush roller mechanism is added, so that rolling brush dust removal operation at the lower ends of ground books is achieved.

Owner:江苏三叶智能装备股份有限公司

Clean pulverized coal combustion industrial boiler device

InactiveCN103388820BEnhanced Mixed BurnoutOvercome the defects of unsatisfactory combustion effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustor

The invention discloses a high-efficiency clean pulverized coal combustion industrial boiler device in the field of combustion devices with combustors. The high-efficiency clean pulverized coal combustion industrial boiler device comprises a hearth, a cyclone pulverized coal burner, a high-temperature vortex burnout device, a transition chamber, a convection flue and a tail flue, wherein the high-temperature vortex burnout device is arranged at an upper outlet of the hearth; the cyclone pulverized coal burner is arranged on the front and rear walls or the left and right walls on the lower part of the hearth in a hedge mode; the transition chamber is arranged on the rear part of the high-temperature vortex burnout device; the inlet of the convection flue is connected with the rear part of the transition chamber; the outlet of the convection flue is connected with the tail flue. According to the device, the defect that the organizing combustion effect in a short and small space of an industrial boiler is not ideal is overcome.

Owner:SHANGHAI JIAOTONG UNIV

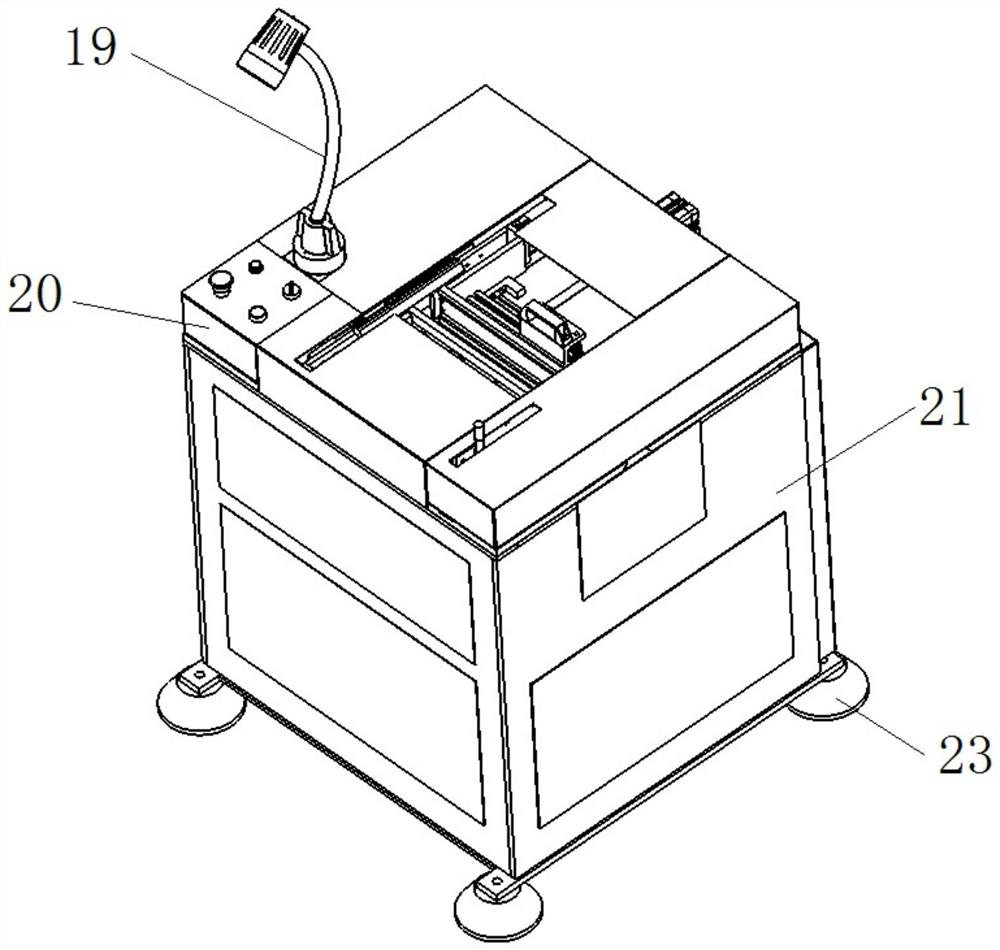

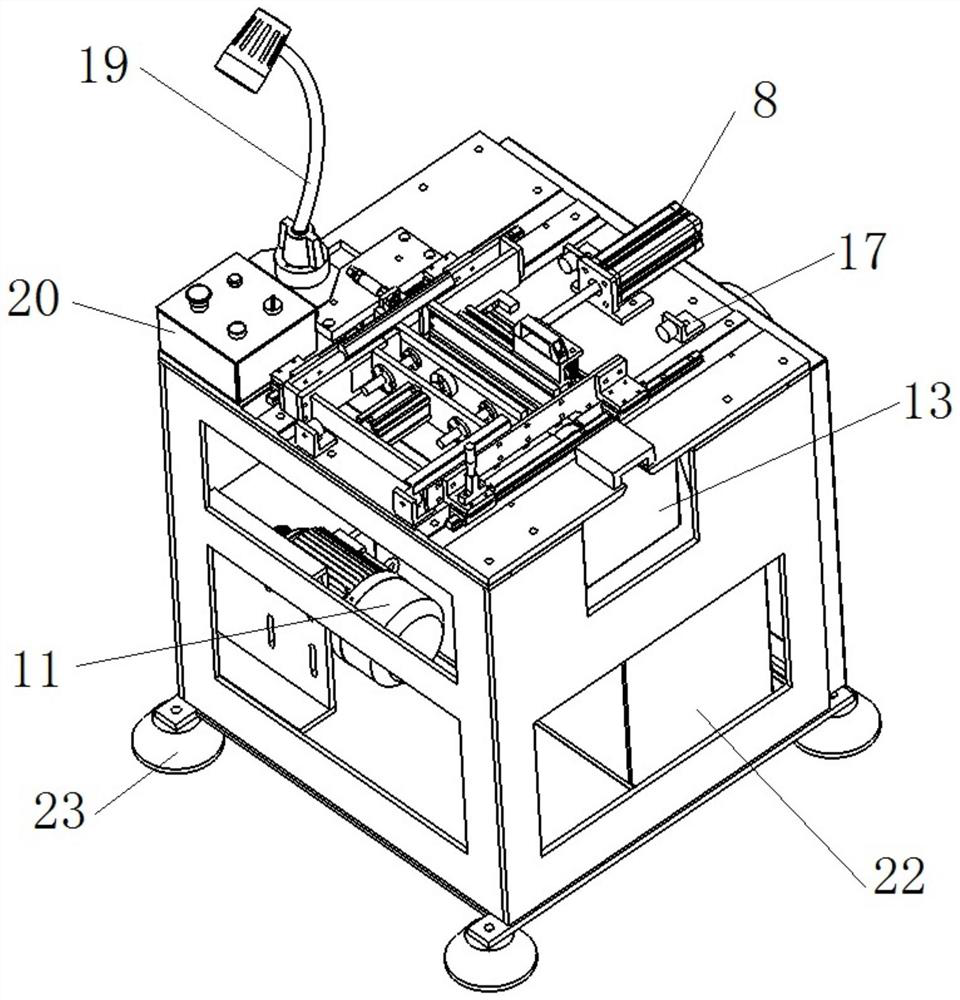

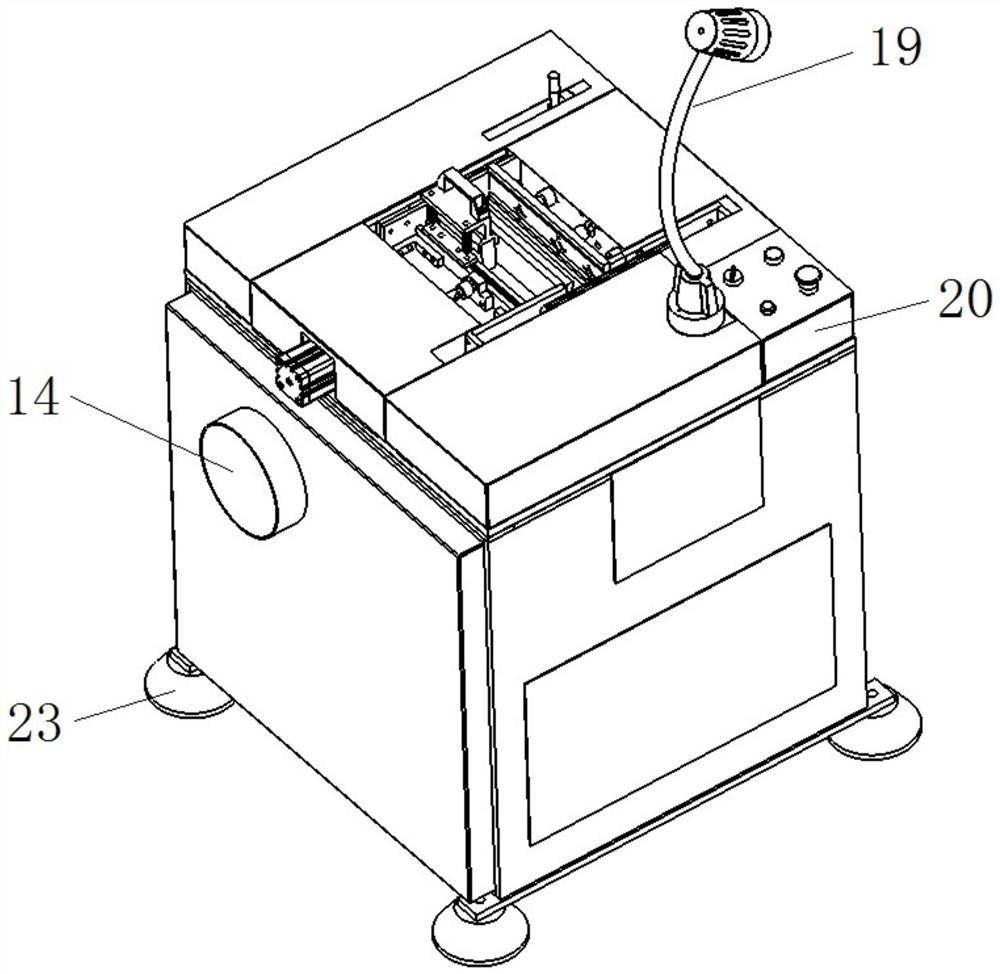

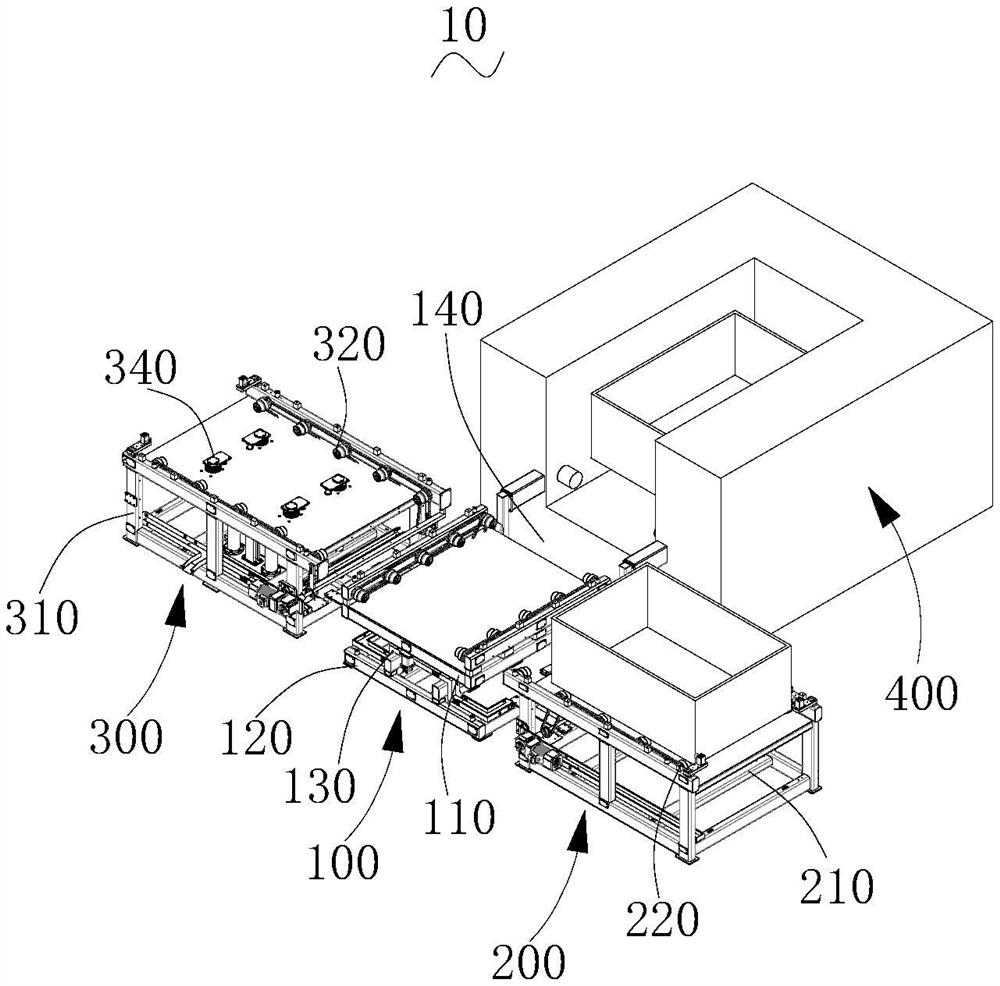

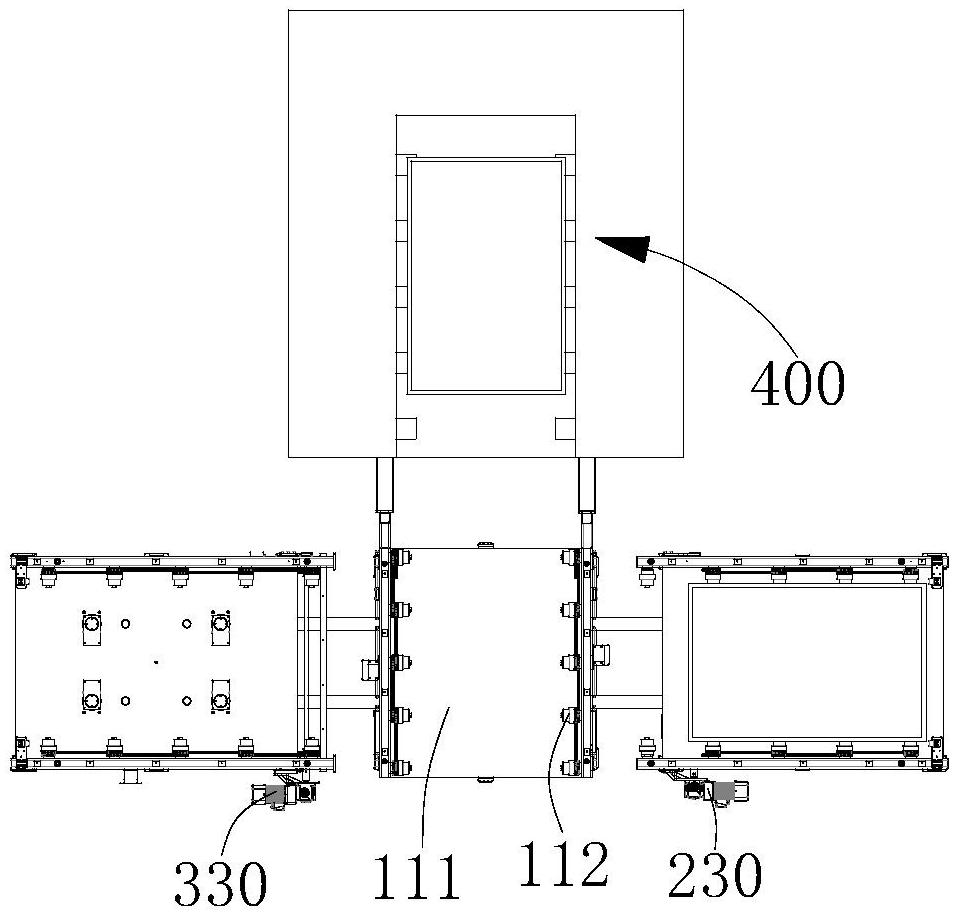

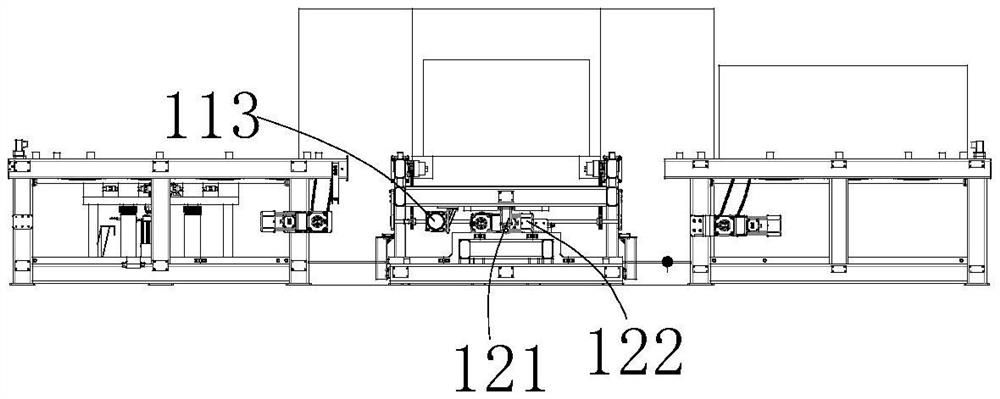

Work box operation system applied to 3D printer

PendingCN113145805ARealize cleaning operationImprove the efficiency of changing boxesAdditive manufacturing apparatusFoundry mouldsRotary stageComputer printing

The invention relates to a work box operation system applied to a 3D printer. The work box operation system comprises a rotating table, a temporary storage table and a material clearing table, wherein the temporary storage table and the material clearing table are arranged on the two sides of the rotating table correspondingly, the rotating table is connected with the 3D printer, the rotating table comprises a bearing mechanism and a rotating mechanism, the bearing mechanism comprises a bearing platform, a first operating part and a first driving part, the rotating mechanism comprises a rotating assembly and a rotating driving part, the temporary storage table comprises a temporary storage frame, a second operating part and a second driving part, and the material clearing table comprises a material clearing frame, a third operating part, a third driving part and a material clearing mechanism. According to the work box operation system applied to the 3D printer, efficient operation of a work box can be achieved, then the working efficiency of the work box is improved, meanwhile, the loss of the work box is small, and safety is high.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com