A bag filter

A bag dust collector and filter bag technology, which is applied in the field of doors and windows, can solve the problems of inability to effectively protect the first layer of dust, achieve the effect of simple and fast dust cleaning operation, ensure dust removal effect, and reduce the use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

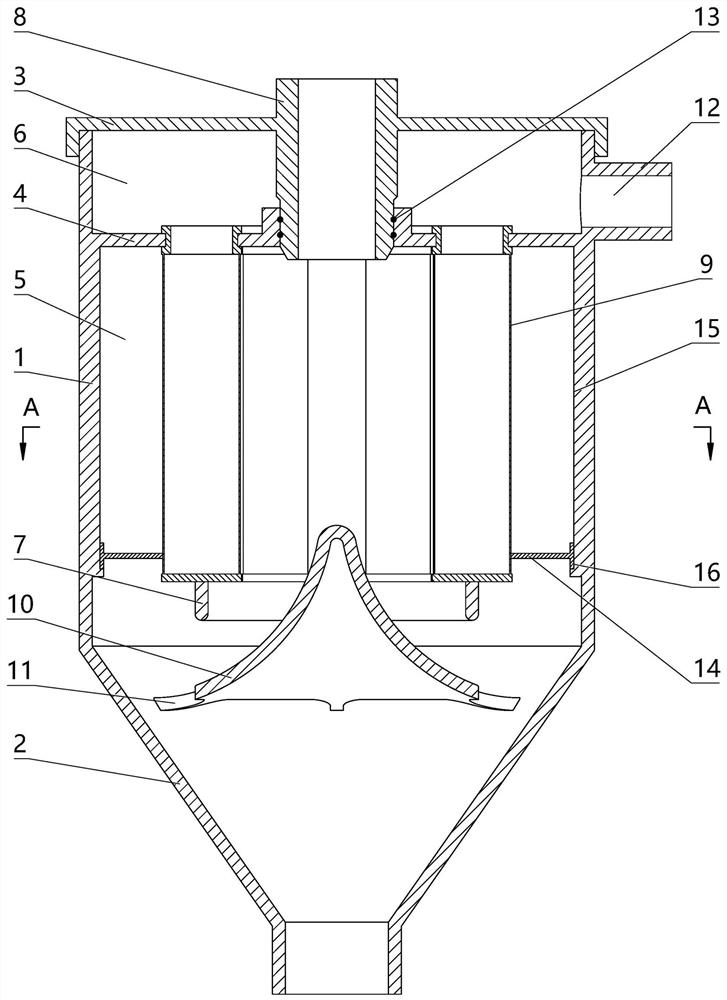

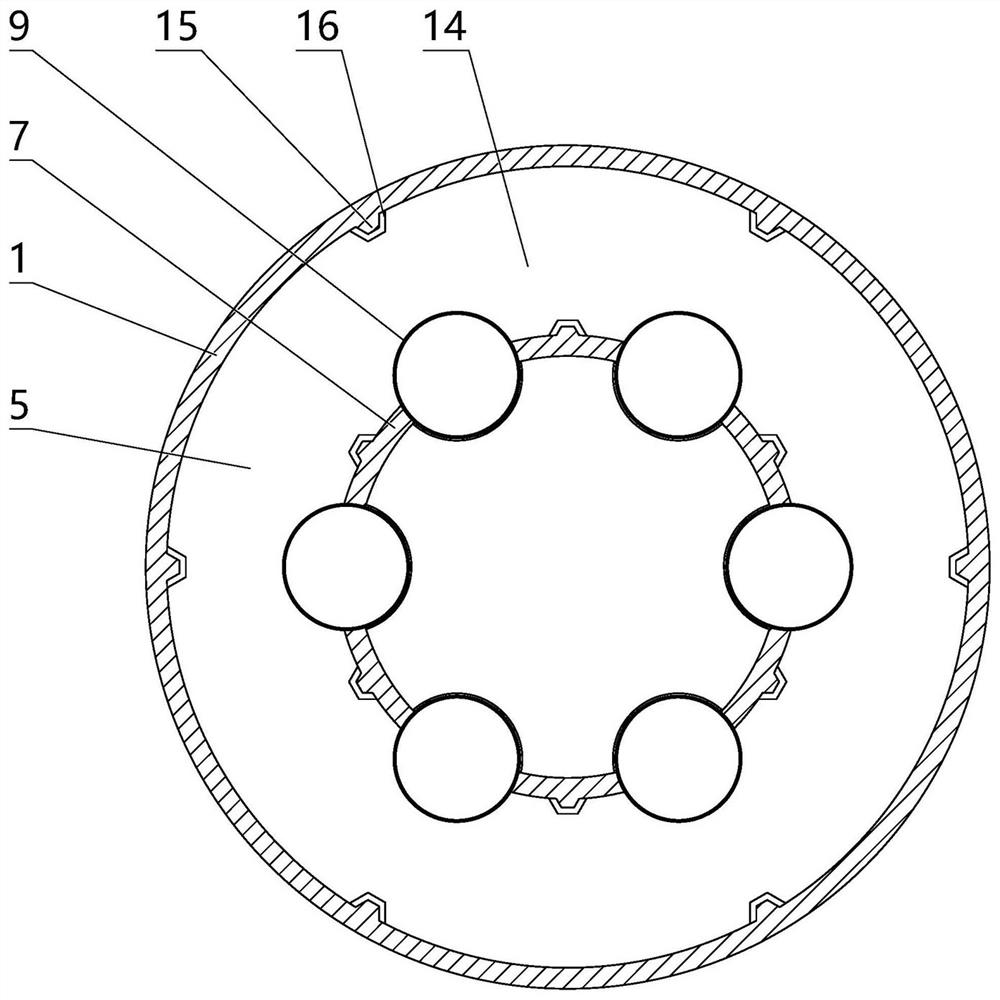

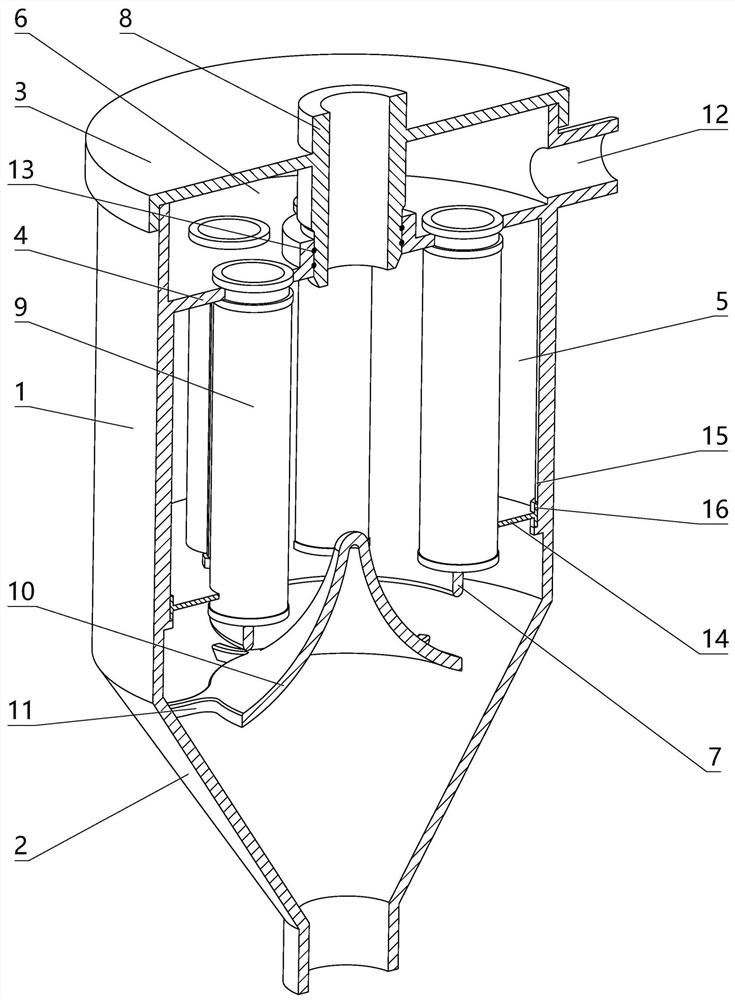

[0010] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0011] Depend on Figure 1 to Figure 3 Given, the present invention includes a vertically arranged cylindrical shell 1, an ash hopper 2, a cover plate 3 and a horizontally arranged partition plate 4 installed on the inside of the shell 1, and the partition plate 4 separates the inner side of the shell 1 It is divided into two parts that do not communicate with each other. The ash hopper 2 is installed under the shell 1, the cover plate 3 is installed above the shell 1, and the mixed flow chamber 5 is formed between the shell 1, the ash hopper 2 and the partition plate 4. , a collecting chamber 6 is formed between the casing 1, the cover plate 3 and the partition plate 4, the partition plate 4 has an inner cylinder 7 placed under the partition plate 4, and the cover plate 3 has a vertical penetration cover plate 3 The upper end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com