Screen scarifier for continuous track lifting operation in turnout zone, and operation method thereof

A screen cleaning machine and operation technology, which is applied in the direction of roads, tracks, and ballast layers, and can solve problems such as rail subsidence in fork areas and unsatisfactory ballast backfilling in ballast beds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

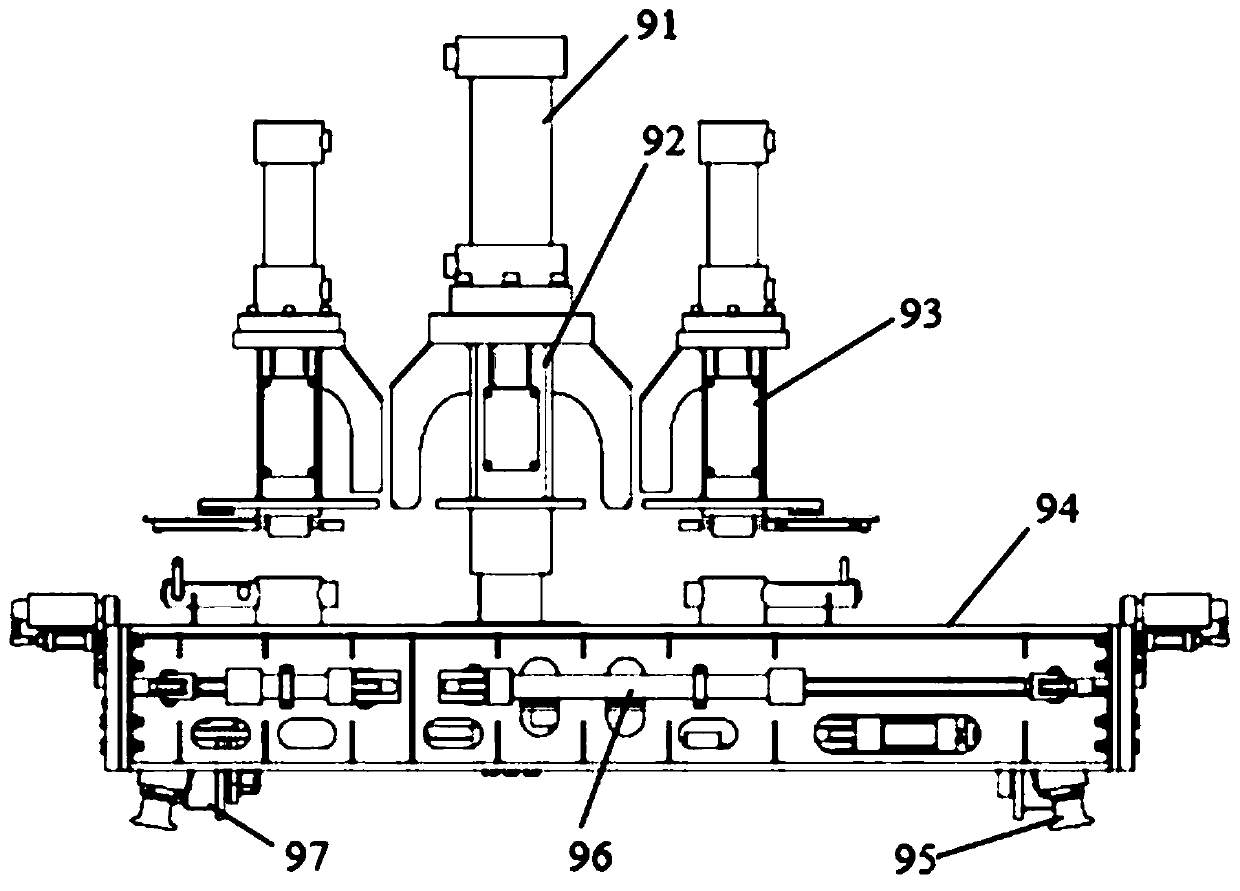

[0036] A sieve cleaning machine capable of working in the fork area, equipped with a continuous lifting device, including a lifting traverse mechanism and lifting clamps, the lifting clamps can be adjusted along the horizontal plane in a direction perpendicular to the rails, and the fork side is double The sets of clamps are used alternately to realize continuous track lifting operations in curves and turnout areas, thereby realizing the full-range cleaning operation of the main line rails of the sieve cleaner, saving labor, and greatly improving the cleaning quality of turnout areas.

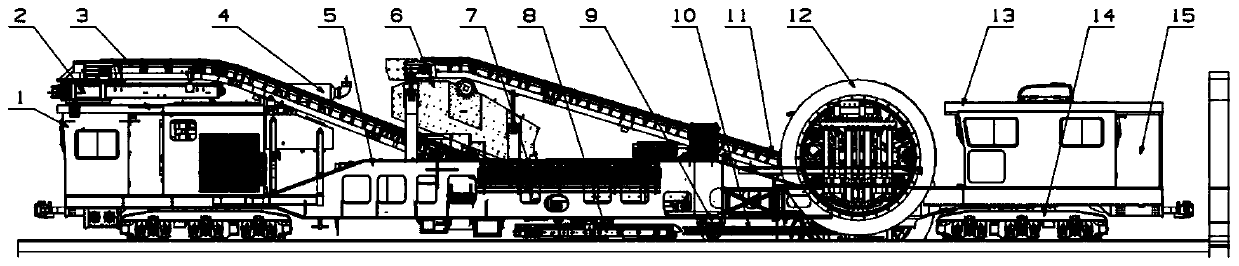

[0037] Such as figure 1 As shown, a screen cleaning machine capable of continuous operation in the fork area is provided, including a traveling driver's cab 1, a rotary dirt conveyor belt 2, a main dirt conveyor belt 3, an engine room 4, a vehicle frame 5, and a vibrating screen 6. Backfill bucket 7, backfill conveyor belt 8, continuous track lifting device 9, side cutter plate 10, mixed ballas...

Embodiment 2

[0045] A sieve cleaning machine for continuous track lifting operations in the turnout area, which solves the problem of the overall sinking of the track row in the turnout area after the turnout cleaning operation due to the absence of a corresponding track lifting device in the turnout area of the existing sieve cleaning machine, and the stone ballast on the ballast bed Problems such as unsatisfactory backfilling.

[0046] A sieve cleaning machine for continuous track lifting operation in a fork area, including a car body and a continuous track lifting device, which is installed under the car body and interposed between a backfill conveyor belt and an excavating device.

[0047] The car body includes the frame and driver's cab.

[0048] The driver's cab includes a traveling driver's cab and / or an operating driver's cab.

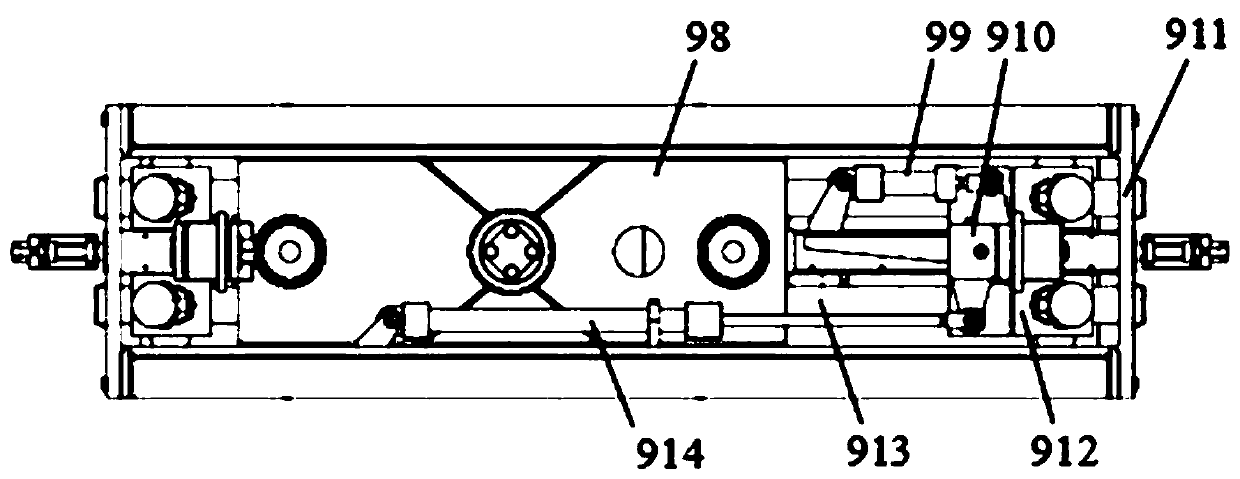

[0049] The continuous track lifting device includes a guide column, a track lifting frame and a track lifting drive mechanism. The guide column includes...

Embodiment 3

[0062] Such as Figure 6 As shown, the specific work steps of a method for continuously lifting the track in a fork area are as follows:

[0063] Execute step 1000, after the screen cleaning machine drives into the fork area, it is judged that the side of the straight strand in the fork area is on the left or right side of the forward direction of the vehicle according to the judgment. Step 1100 is executed to adjust the screen cleaning machine. Adjust the corresponding position, put down the continuous lifting device, and put the end with the fixed guide wheel corresponding to the straight strand side of the fork area, and the end with the movable guide wheel corresponding to the split side of the straight strand in the fork area. Execute step 1200 to perform the lifting operation. The double sets of track clamps on the straight strand side and the guide wheels are always in a clamping state on the rail, and the double sets of track clamps on the split side are alternately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com