Thermal-shrinkage insulation tube continuous expansion process and device

A technology of expansion device and insulating tube, applied in the field of expansion process, can solve the problems of uneven removal of both ends of the port, material cannot be recycled, material waste, etc., and achieves the reduction of energy consumption, significant environmental and economic benefits, and reduction of complicated procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

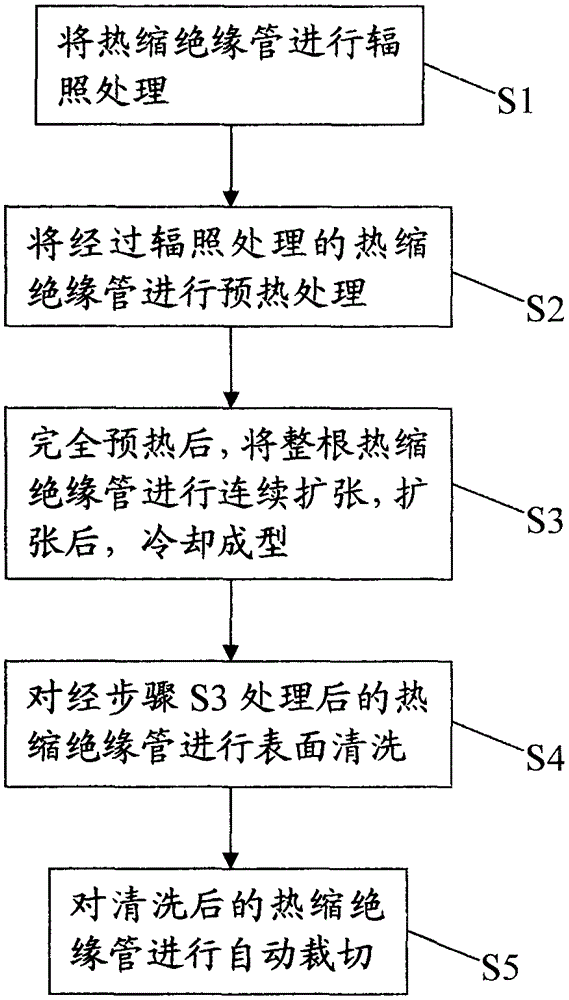

[0031] Such as figure 1 As shown, the continuous expansion process of the heat-shrinkable insulating tube of the present invention sequentially includes: irradiation, preheating, continuous expansion, cleaning, and cutting.

[0032] S1. The heat-shrinkable insulating tube is irradiated.

[0033] This step is used to realize the irradiation in the continuous expansion process. In step S1, after the heat-shrinkable insulating tube is irradiated, it does not need to be cut according to the traditional process.

[0034] S2. Preheat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap