Production equipment and method for stone flake composite board

A production method and technology for composite panels, which are applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of difficult to meet market requirements, single plane shape, and difficult processing, and reduce the cumbersome process of gluing and improve the internal quality. The effect of accelerating hardening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

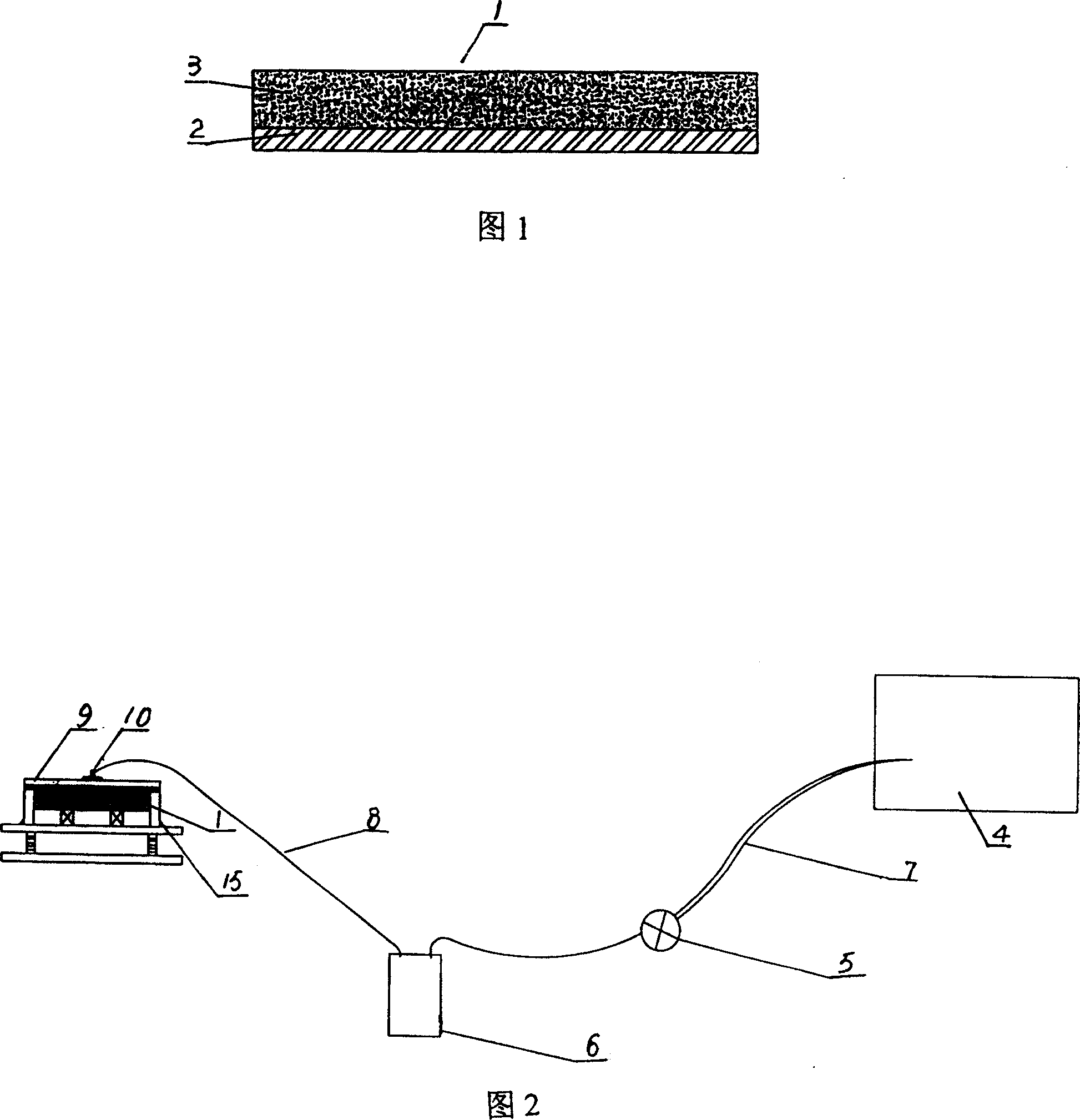

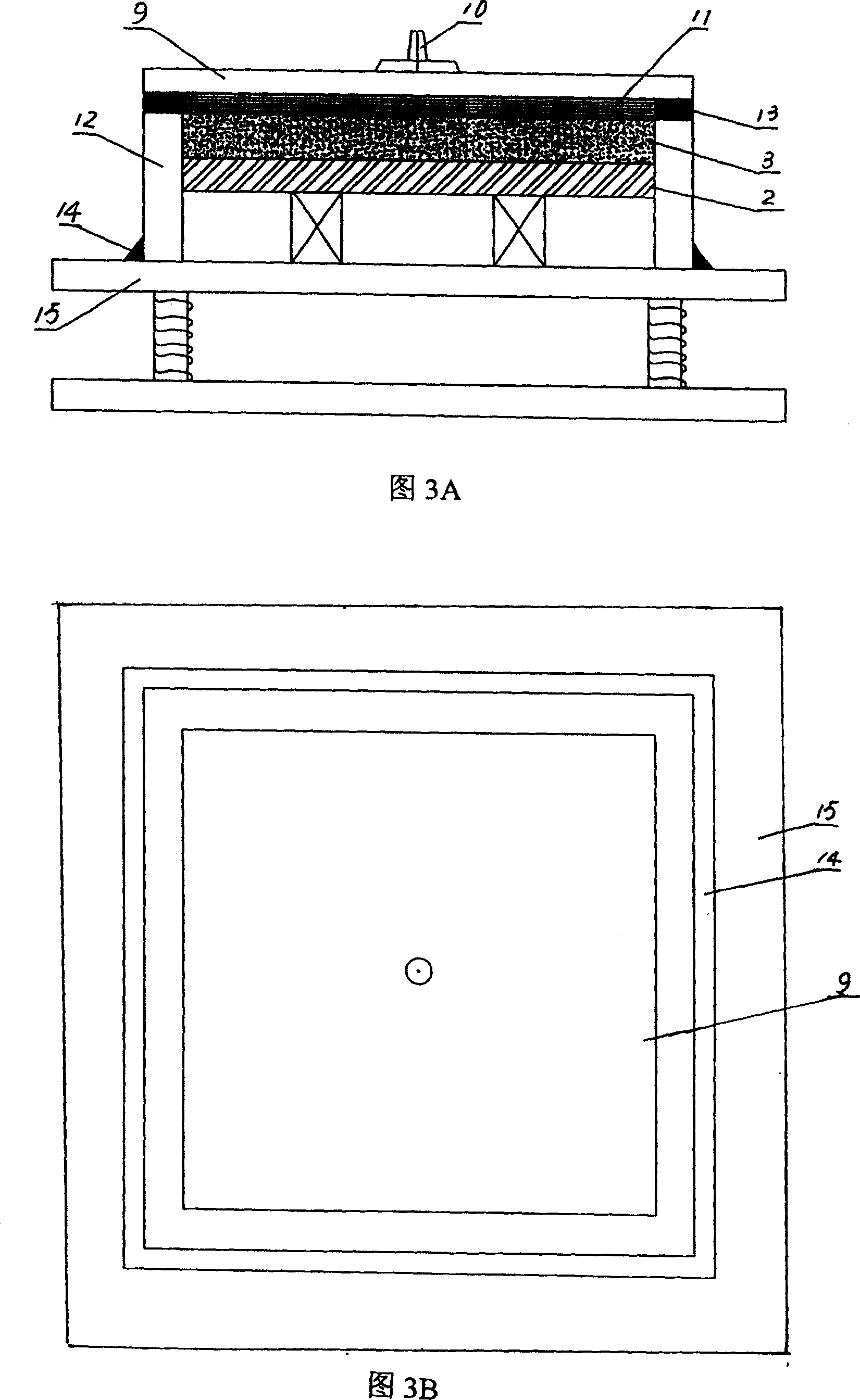

[0039] Referring to the accompanying drawings 1-3 stone sheet composite board production equipment:

[0040] The stone flake composite board 1 includes a stone flake surface layer 2 and a connected glass fiber reinforced cement (GRC) structural layer 3 . Production equipment includes: 1) Vacuum dehydration combination unit: vacuum dehydrator 4, vacuum tube 7, connector 5, metering water collection tank 6, vacuum suction pipe 8, vacuum dehydrator 4 passes through vacuum tube 7, and vacuum connector 5 and metering water collection tank 6 are connected, and the metering water collection tank 6 is connected with the vacuum dehydration workbench through the vacuum suction pipe 8. 2) The combined workbench for vacuum forming is equipped with: vibrating workbench 15, frame mold 12, vacuum suction cup 9, and correspondingly configured sealing ring 13, sealing strip 14, filter layer 11, and water suction nozzle 10. The frame mold 12 is placed on the vibrating table 15, and the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com