Flexible metal laminate

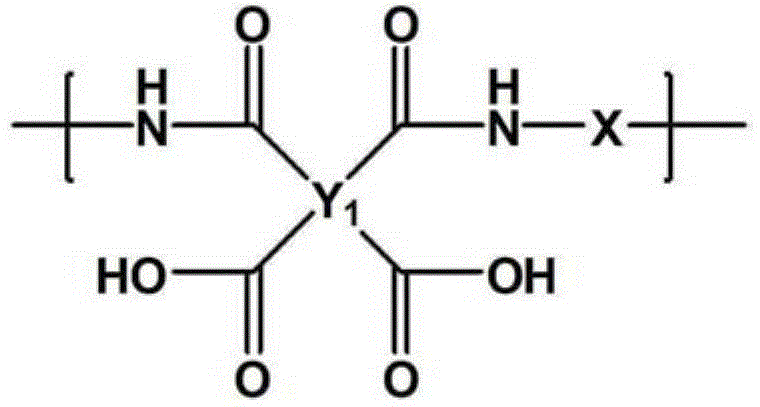

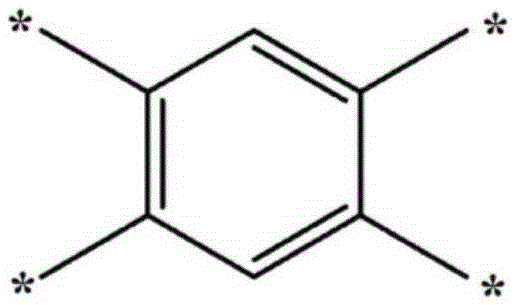

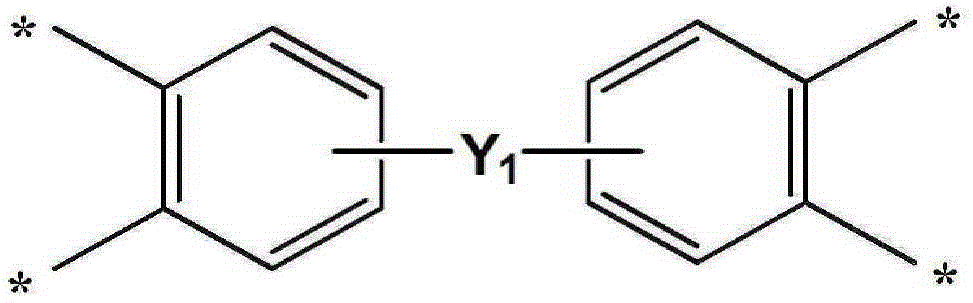

一种柔性金属、层压板的技术,应用在金属层状产品、涂层、分层产品等方向,能够解决降低热塑性聚酰亚胺层粘合力等问题,达到优化热膨胀系数、低介电常数、高度弹性热膨胀系数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0106] Preparation Example 1: Preparation of polyamic acid solution (P1) containing fluorine-based resin

[0107] Fill a 1L polyethylene (PE) bottle with nitrogen, and add 765g of dimethylacetamide (DMAc), 160g of polytetrafluoroethylene (PTFE) fine powder (particle size: 0.1 to 2.0μm), And 765 g of beads with a diameter of 2 mm. When the mixture is stirred in a high-speed ball mill, the PTFE is dispersed.

[0108] Add 19.5g of the solution in which PTFE is dispersed, 154g of dimethylacetamide, 12.15g of pyromellitic dianhydride and 17.85g of 2,2'-bis(trifluoromethyl)-4 to a 500mL round bottom flask, 4'-diaminobiphenyl, and stirred with a stirrer, while allowing nitrogen to flow in the mixture at 50 ℃ for 10 hours, thereby obtaining a polyamic acid solution (P1) with a density of about 20,000 cps (in the solid content of PTFE Content: 10% by weight).

preparation Embodiment 2

[0109] Preparation Example 2: Preparation of polyamic acid solution (P2)

[0110] Add 154g of dimethylacetamide, 12.15g of pyromellitic dianhydride and 17.85g of 2,2'-bis(trifluoromethyl)-4,4'-diaminobiphenyl to a 500mL round bottom flask, and stir The vessel was stirred while flowing nitrogen in the mixture at 50°C for 10 hours, thereby obtaining a polyamic acid solution (P2) having a density of about 20,000 cps.

preparation Embodiment 3

[0111] Preparation Example 3: Preparation of thermoplastic polyamic acid solution (P2)

[0112] Add 154g of dimethylacetamide, 9g of pyromellitic dianhydride (PMDA) and 17g of 2,2'-bis[4](4-aminophenoxy)phenylpropane into a 500mL round bottom flask, and use a stirrer While stirring, nitrogen was allowed to flow in the mixture at 50°C for 10 hours, thereby obtaining a polyamic acid solution (P3) having a density of about 3000 cps.

[0113] [Example and Comparative Example: Manufacturing of Flexible Metal Laminate]

[0114] On the matte surface of the copper foil (thickness: 12 μm), the polyamic acid solution of the preparation example was applied in the above-mentioned order, and after each application of the polyamic acid solution, it was dried at 100° C. for 10 minutes.

[0115] In addition, after coating and drying were completed, the dried product was started to be heated from room temperature to 350°C in a nitrogen oven and cured at 350°C for 30 minutes.

[0116] After the curing w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com