Method for preparing cement dispersant with both high water reduction effect and viscosity reduction effect

A cement dispersant and viscosity-reducing technology, which is applied in the field of preparation of copolymer cement dispersants, can solve the problems of water-reducing performance reduction, viscosity reduction, and low economic benefits, and achieve water-reducing performance improvement, complexation reduction, and economical significant effect

Active Publication Date: 2016-05-25

JIANGSU SOBUTE NEW MATERIALS +3

View PDF11 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] CN200480011979 improves the viscosity of concrete by introducing hydrophobic long-chain alkyl acrylates into the conventional structure, but the introduction of hydrophobic side chains will cause a significant decline in water-reducing performance, and this method is limited to the improvement of viscosity

CN20091077550.2 On the basis of polycarboxylic acid mother liquor and early strength agent, compound polyethylene glycol as a viscosity-reducing component to achie

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

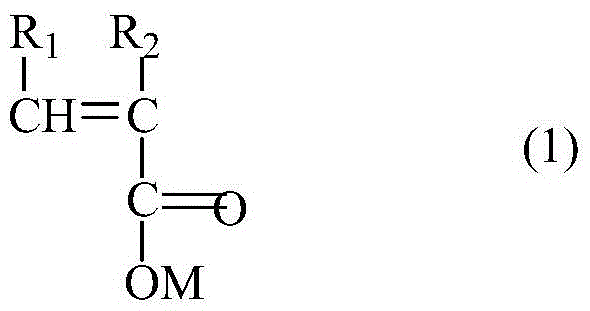

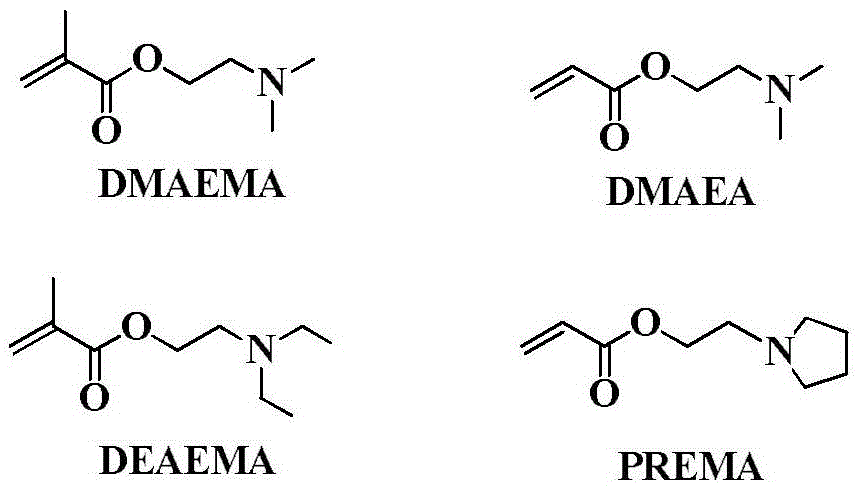

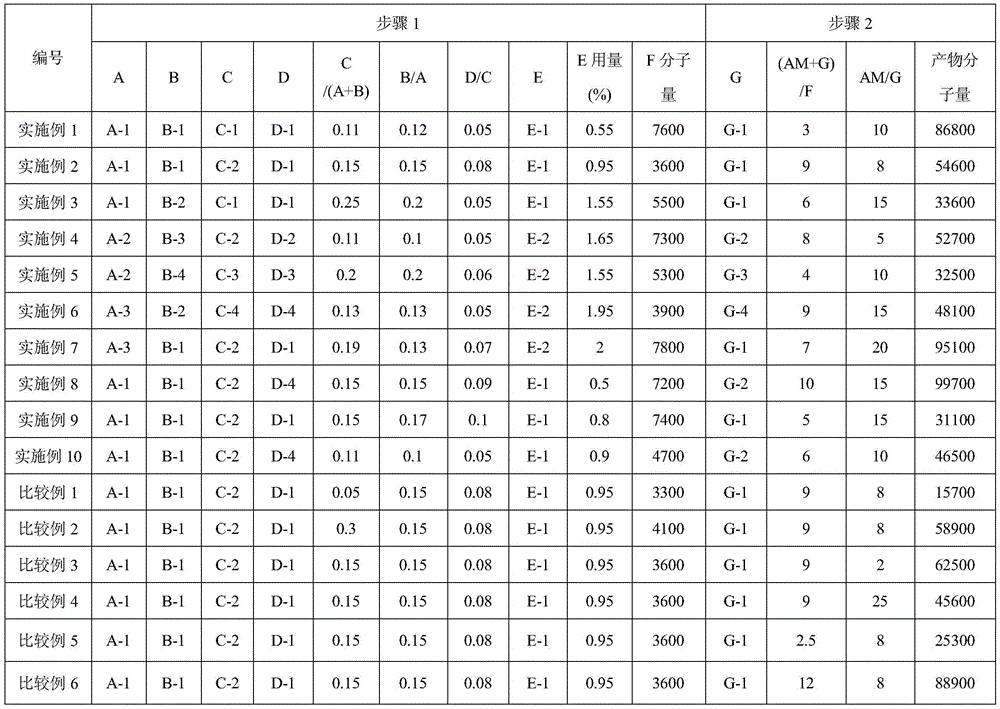

The invention discloses a method for preparing cement dispersant with both a high water reduction effect and a viscosity reduction effect. The method comprises the following steps: unsaturated carboxylic acid monomer A, unsaturated sulfoacid monomer B, special monomer C with ultraviolet activity and ultraviolet catalysis monomer D are subjected to thermal-induced polymerization in an aqueous solution by adopting an initiator E to obtain a macromolecule F with ultraviolet activity; under irradiation of ultraviolet light, acrylamide (AM) and cationic monomer G are slowly dropped into the prepared active macromolecule F aqueous solution for graft polymerization reaction, and a final cement dispersant molecule is obtained. The cement dispersant prepared with the method has relatively high water reduction ratio and outstanding viscosity reduction effect at the same time, and the economic benefit is outstanding.

Description

technical field [0001] The invention relates to a preparation method of a copolymer cement dispersant with a relatively high water-reducing rate and an obvious viscosity-reducing effect, and belongs to the technical field of concrete admixtures. Background technique [0002] Modern concrete structures are gradually developing in the direction of super high-rise, long-span and complex structural systems, which put forward higher requirements for the mechanical properties and construction performance of concrete, and greatly promoted the development of concrete pumping construction technology. High-strength concrete of C60 and above grades has begun to be used in super high-rise buildings, long-span bridges and super-high cable towers due to its many performance advantages such as improving bearing capacity, reducing structural weight and saving materials. However, the water-binder ratio of high-strength concrete is low, the amount of cementitious material is large, the amount...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F220/06C08F212/14C08F220/34C08F220/36C08F220/38C08F220/56C08F220/58C08F222/02C08F226/02C08F228/02C08F265/02C08F265/04C08F267/02C04B24/16C04B103/40

CPCC04B24/163C08F220/06C08F220/36C08F222/02C08F265/02C08F265/04C08F267/02C04B2103/408C08F212/14C08F220/56C08F220/34C08F226/02C08F220/382C08F220/585C08F228/02

Inventor 黄振杨勇冉千平舒鑫周栋梁刘金芝翟树英

Owner JIANGSU SOBUTE NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com