Hydroxyalkyl composite halogenated polycarboxylate slump retaining agent and ATRP preparation method thereof

A technology of hydroxyalkyl and polycarboxylic acid, which is applied in the preparation of polycarboxylic acid slump-retaining agent, hydroxyalkyl complex halogenated polycarboxylic acid slump-retaining agent and its ATRP preparation field, which can solve the problem of difficult industrial production and long production cycle , high energy consumption and other issues, to achieve the effect of gentle reaction conditions, enhanced dispersion ability, and single molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

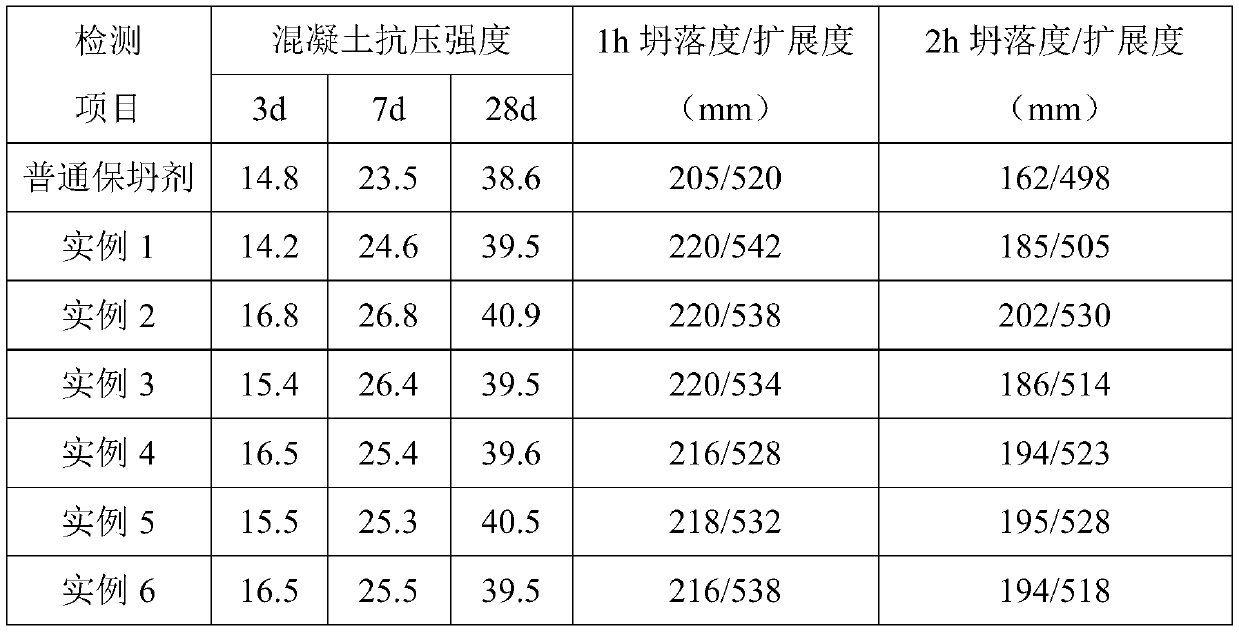

Examples

example 1

[0038] A kind of ATRP preparation method of polycarboxylic acid slump-retaining agent of hydroxyalkyl compound halogenation, the total mass of raw materials is 1000 parts, the mass fraction is about 40%, mainly prepared from the following components:

[0039] Vinyl butyl ether polyoxyethylene ether: 362 parts

[0040] Hydroxyethyl acrylate: 22 parts

[0041] Methacrylic: 3 parts

[0042] Propyl alcohol: 10 parts

[0043] Azobisisoheptanonitrile: 0.8 parts

[0044] Mercaptoethanol: 0.7 parts

[0045] N,N,N',N'-Tetramethylethylenediamine: 0.8 parts

[0046] Cuprous bromide: 0.06 parts

[0047] The rest is water.

[0048] Step 1: Put 3 parts of methacrylic alkane, 10 parts of propylene alcohol, and 100 parts of deionized water in the No. 1 reactor, add A and B materials dropwise, and the dropping time is 2-3 hours, of which A material is 0.8 parts of distilled water A mixture of nitrogen diisoheptanonitrile and 50 parts of deionized water; material B is a mixture of 0.7 part...

example 2

[0051] A kind of ATRP preparation method of polycarboxylic acid slump-retaining agent of hydroxyalkyl compound halogenation, the total mass of raw materials is 1000 parts, the mass fraction is about 40%, mainly prepared from the following components:

[0052] Vinyl butyl ether polyoxyethylene ether: 360 parts

[0053] Hydroxypropyl acrylate: 20 parts

[0054] Pentenane: 6 parts

[0055] Methacryl alcohol: 8 parts

[0056] Dibenzoyl peroxide: 1.2 parts

[0057] Mercaptopropanol: 0.6 parts

[0058] N,N,N',N",N'-pentamethacrylate divinyltriamine: 0.6 parts

[0059] Ferrous bromide: 0.08 parts

[0060] The rest is water.

[0061] Step 1: Put 6 parts of pentene, 8 parts of methacryl alcohol, and 100 parts of deionized water in the No. 1 reactor, add A and B materials dropwise, and the dropping time is 2-3 hours, of which A material is 1.2 parts A mixture of dibenzoyl peroxide and 50 parts of deionized water; material B is a mixture of 0.6-0.8 parts of mercaptopropanol and 50...

example 3

[0064] A kind of ATRP preparation method of polycarboxylic acid slump-retaining agent of hydroxyalkyl compound halogenation, the total mass of raw materials is 1000 parts, the mass fraction is about 40%, mainly prepared from the following components:

[0065] Vinyl butyl ether polyoxyethylene ether: 364 parts

[0066] Hydroxyethyl acrylate: 19 parts

[0067] Isopentenane: 8 parts

[0068] Propyl alcohol: 7 parts

[0069] Azobisisovaleronitrile: 1.1 parts

[0070] Mercaptoethanol: 0.8 parts

[0071] N,N,N',N',N",N"-n-butylhexamethacrylate triethylenetetramine: 1.4 parts

[0072] Cuprous bromide: 0.03 parts

[0073] The rest is water.

[0074] Step 1: Put 8 parts of isopentane, 7 parts of propylene alcohol, and 100 parts of deionized water in the No. 1 reactor, add A and B materials dropwise, and the dropping time is 2-3 hours, of which A material is 1.1 parts of distilled water A mixture of nitrogen diisovaleronitrile and 50 parts of deionized water; material B is a mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com