ATRP preparation method for polycarboxylate slump retaining agent based on phenyl-hydroxyl halogenation polymerization

A phenylhydroxyl, halogenated polymer technology, applied in the preparation of polycarboxylic acid slump-retaining agent, the field of ATRP preparation of polycarboxylic acid slump-retaining agent, can solve the problems of excessive loss, large slump, etc., to achieve the reaction conditions The effect of smoothing, dispersing ability is enhanced, and the effect of reducing the generation of closed chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

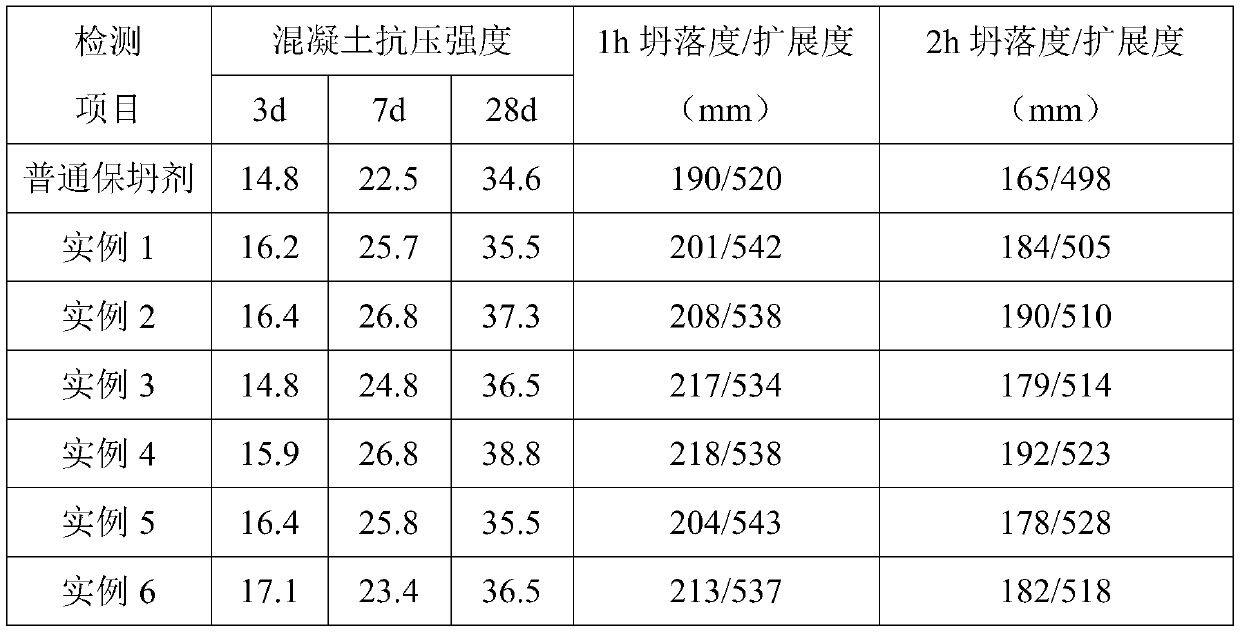

Examples

example 1

[0039] An ATRP preparation method of polycarboxylic acid slump retention agent based on phenylhydroxyl halogenation polymerization, the total mass of raw materials is 1000 parts, the mass fraction is about 40%, and it is mainly prepared from the following components:

[0040] Vinyl butyl ether polyoxyethylene ether: 345 parts

[0041] Hydroxyethyl acrylate: 28 parts

[0042] 1-allyl-2-fluorobenzene: 5 parts

[0043] Propylene hydroxy: 18 parts

[0044] Ammonium persulfate: 1.2 parts

[0045] Mercaptopropanol: 0.9 parts

[0046] N,N,N',N'-tetramethylethylenediamine: 0.8 parts

[0047] Cuprous bromide: 0.1 part

[0048] The rest is water.

[0049] Step 1: Put 5 parts of 1-allyl-2-fluorobenzene, 18 parts of propylene hydroxy, and 100 parts of deionized water in the No. 1 reaction kettle, and drop materials A and B. The dropping time is 2h, of which material A 1.2 parts of ammonium persulfate, 50 parts of deionized water mixed liquid; B material is 0.9 parts of mercaptopropanol, 50 parts of dei...

example 2

[0052] An ATRP preparation method of polycarboxylic acid slump retention agent based on phenylhydroxyl halogenation polymerization, the total mass of raw materials is 1000 parts, the mass fraction is about 40%, and it is mainly prepared from the following components:

[0053] Vinyl butyl ether polyoxyethylene ether: 347 parts

[0054] Hydroxypropyl acrylate: 27 parts

[0055] 1-allyl-4-fluorobenzene: 10 parts

[0056] 4-(propylene hydroxy)benzoic acid: 12 parts

[0057] Azobisisobutyronitrile: 1.5 parts

[0058] Mercaptoethanol: 0.6 parts

[0059] N,N,N',N″,N'-pentamethylmethacrylate divinyltriamine: 1.1 parts

[0060] Cuprous chloride: 0.05 parts

[0061] The rest is water.

[0062] Step 1: Put 10 parts of 1-allyl-4-fluorobenzene, 12 parts of 4-(propylene hydroxy)benzoic acid, and 100 parts of deionized water in the No. 1 reaction kettle, drop materials A and B, and add time It is 1.5h, where material A is 1.5 parts of azobisisobutyronitrile and 50 parts of deionized water; material B is 0...

example 3

[0065] An ATRP preparation method of polycarboxylic acid slump retention agent based on phenylhydroxyl halogenation polymerization, the total mass of raw materials is 1000 parts, the mass fraction is about 40%, and it is mainly prepared from the following components:

[0066] Vinyl butyl ether polyoxyethylene ether: 349 parts

[0067] Hydroxyethyl acrylate: 26 parts

[0068] Styrene: 7 parts

[0069] 2-propylene hydroxyphenyl boric acid: 13 parts

[0070] Azobisisoheptanonitrile: 1.3 parts

[0071] Mercaptopropanol: 0.8 parts

[0072] N,N,N',N',N",N"-hexamethacrylate n-butyl trivinyltetraamine: 1.5 parts

[0073] Cuprous bromide: 0.02 parts

[0074] The rest is water.

[0075] Step 1: Put 7 parts of styrene, 13 parts of 2-propenylhydroxyphenylboronic acid, and 100 parts of deionized water in the No. 1 reaction kettle, and add materials A and B dropwise for 1 hour, of which material A is 1.3 parts even Nitrogen diisohepta nitrile, 50 parts of deionized water mixed liquid; B material is 0.8 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com