On-site experience type oil press combination rack

An experiential, oil press technology, applied in the direction of edible oil/fat, fat oil/fat production, fat oil/fat refining, etc., can solve the problems of large volume, hinder market development, and cannot be easily handled, and expand the marketing scope. , the effect of improving the added value of products and the point of economic growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

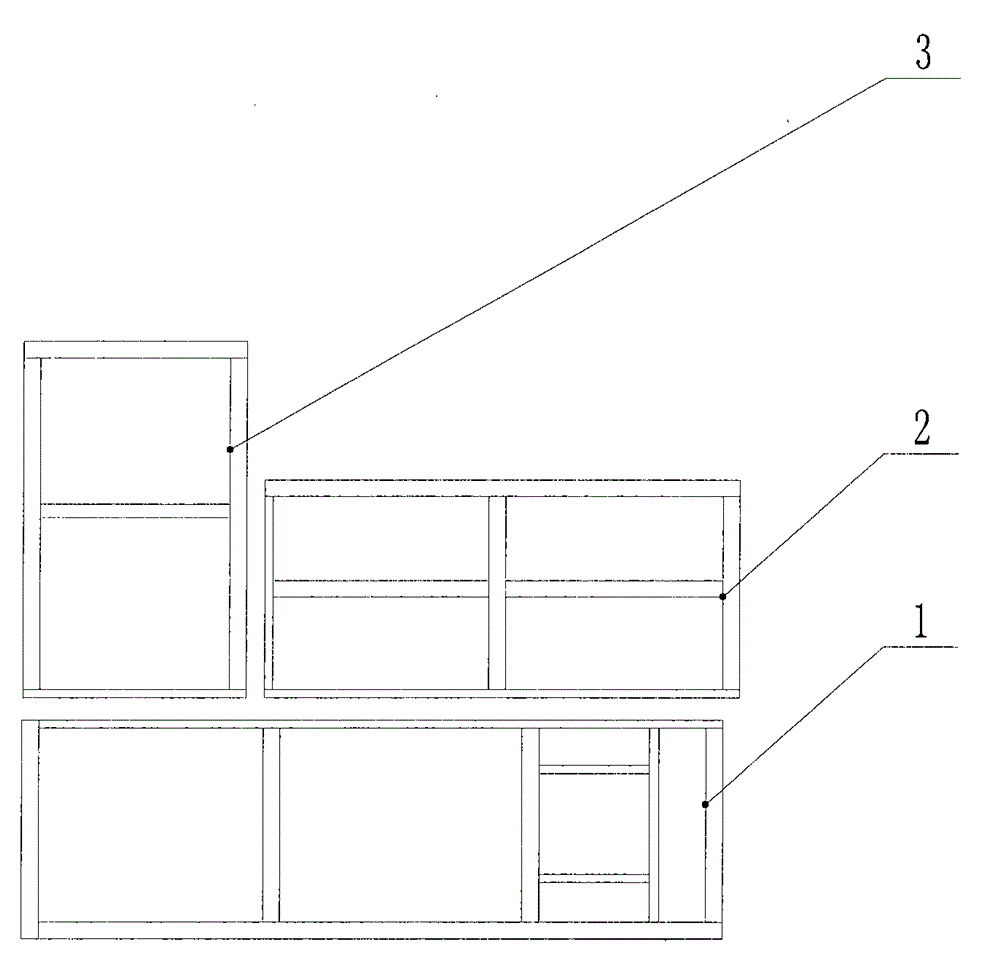

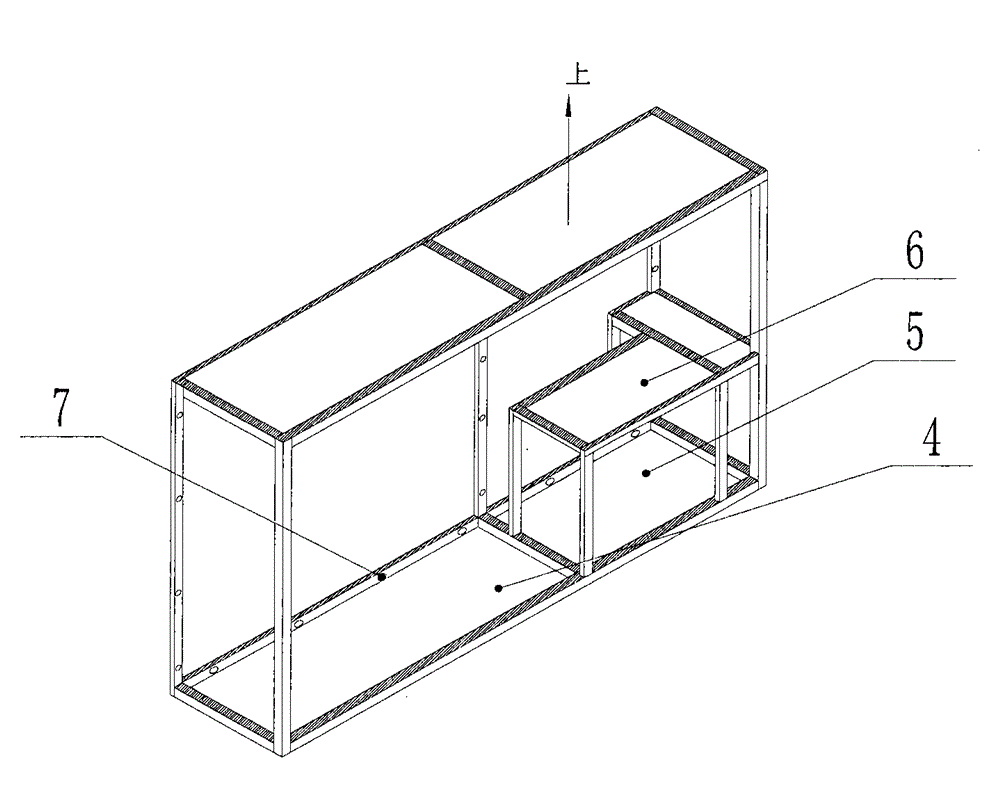

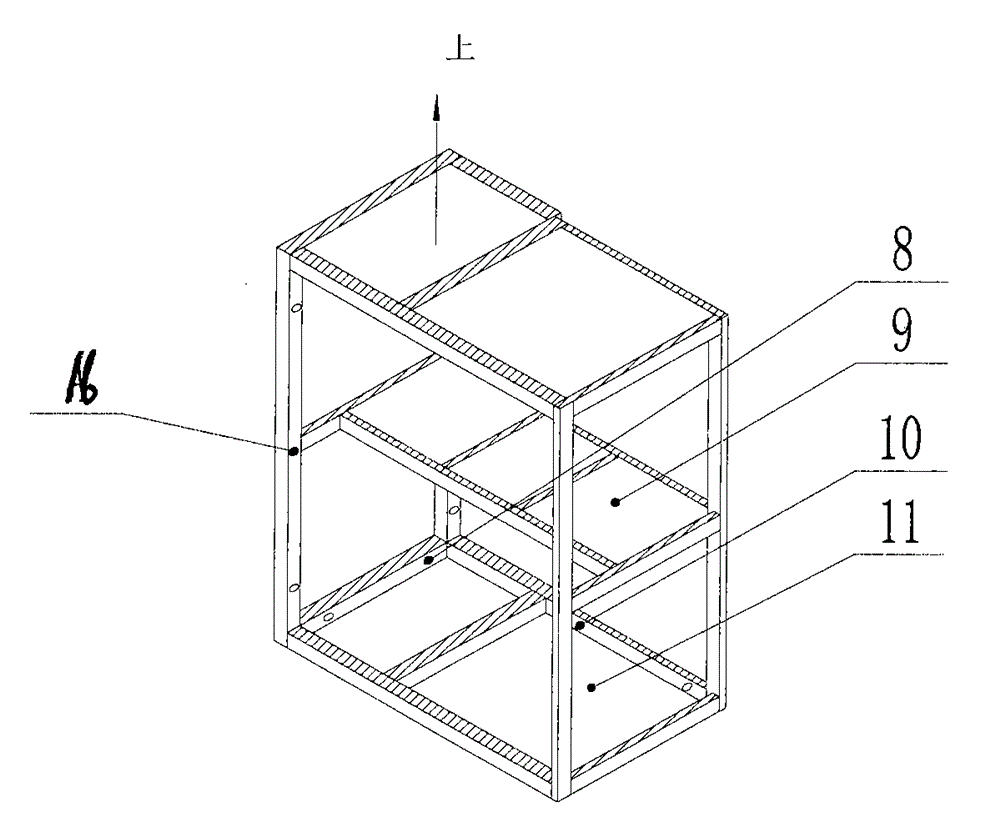

[0013] Such as figure 1 , figure 2 , image 3 As shown, the on-site experiential oil press combined frame consists of a unit frame with a length of 280CM, 203CM, and 131CM, a width of 80CM, and a height of 160CM. The combined machine frame is made of square metal pipe profiles and processed by welding. The one-unit frame 1 and the second-unit frame 2 adopt a two-layer structure, and the three-unit frame 3 adopts a ladder-shaped three-layer structure; the one-unit frame 1 is set in a left and right structure, which is divided into: a seed frying room 4 and a pressing room; The seed frying chamber 4 is arranged in one layer structure, and the seed frying machine is placed; the squeezing chamber is arranged in a two-layer structure; It is used to place the drawer-type crude oil tank. A No. 1 bolt hole 7 is provided on the bottom square metal tube of the unit frame 1 for bolt connection. The two-unit frame 2 is set in a two-layer structure, the upper layer is the oil filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap