A semi-integrated i-type furnace to produce the reaction tank cover for titanium sponge

A technology of reaction tank and titanium sponge is applied in the field of semi-integrated I-type furnace to produce reaction tank cover for titanium sponge, which can solve the problems of difficulty in ensuring the quality of magnesium plate installation, high labor intensity for workers in distilling, and poor sealing effect of titanium lumps. , to achieve the effect of simple structure, reduced labor intensity and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention.

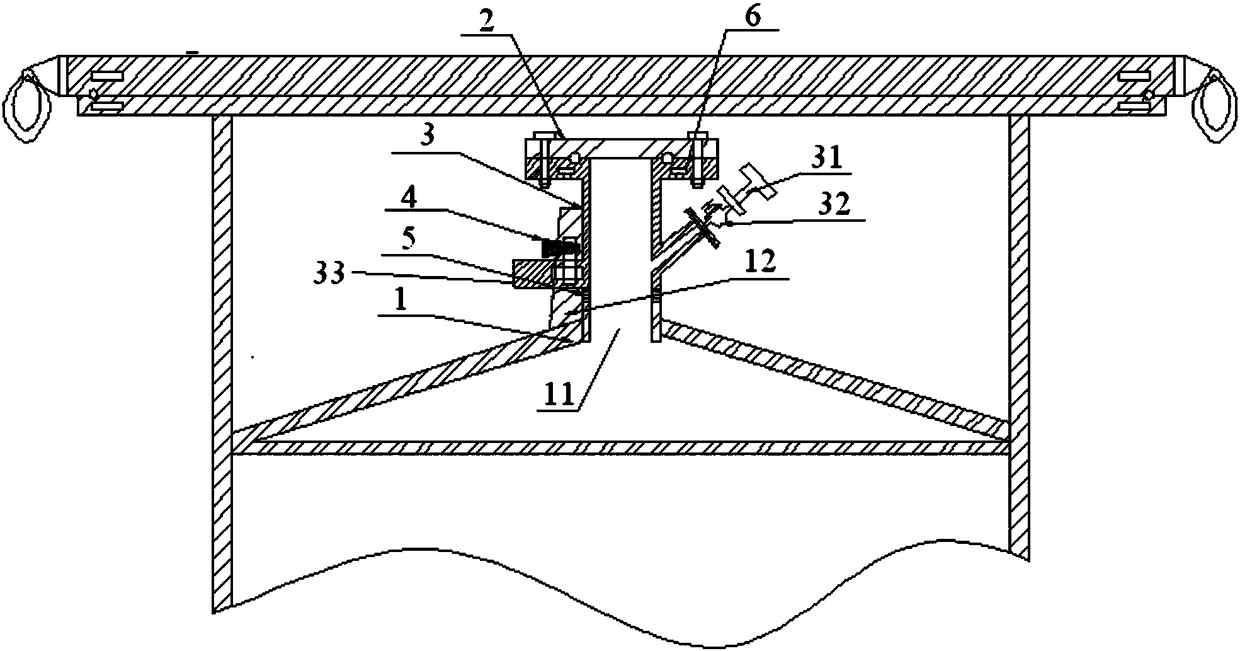

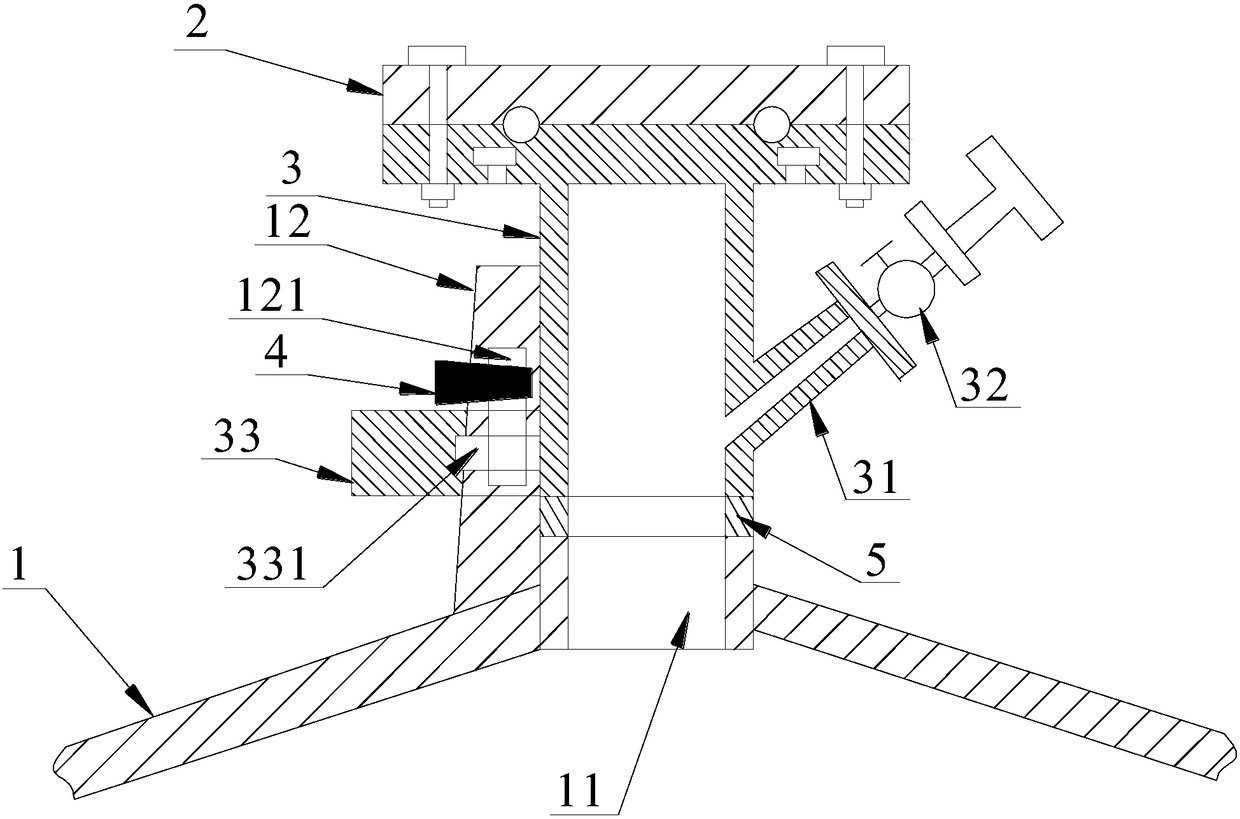

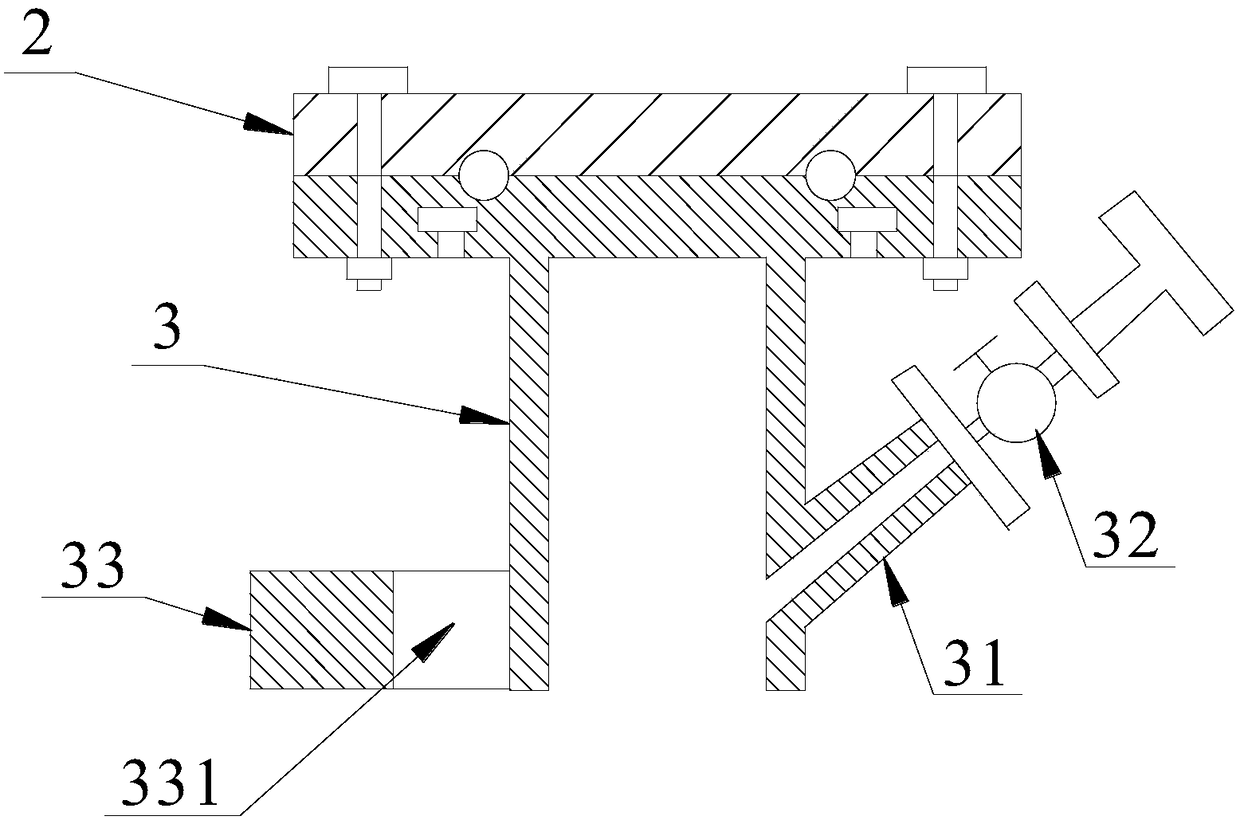

[0023] like Figure 1 to Figure 7 As shown, the present invention includes a reaction tank cover 1 and a sealed magnesium plate 2, and also includes a distillation passage tube 3, the bottom of the distillation passage tube 3 is detachably and sealingly connected with the cover mouth 11 of the reaction tank cover 1, the The top of the distillation passage cylinder 3 is in sealing connection with the sealing magnesium plate 2 , a feed pipe 31 is connected to the wall of the distillation passage cylinder 3 , and a stop valve 32 is installed on the feed pipe 31 . When it is necessary to inflate, connect the gas source pipeline to the feeding pipe 31. The connection method can be a flange connection, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com