Nozzles and Cleaning Carts

The technology of a straw and a mouth seat is applied in the field of sanitation engineering machinery, which can solve the problems of poor adaptability of partially uneven road surfaces, and achieve the effect of improving the suction effect and good adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that the features in the various embodiments of the present invention may be combined with each other in the absence of explicit limitation or conflict. The present invention will be described in detail below with reference to the accompanying drawings and examples.

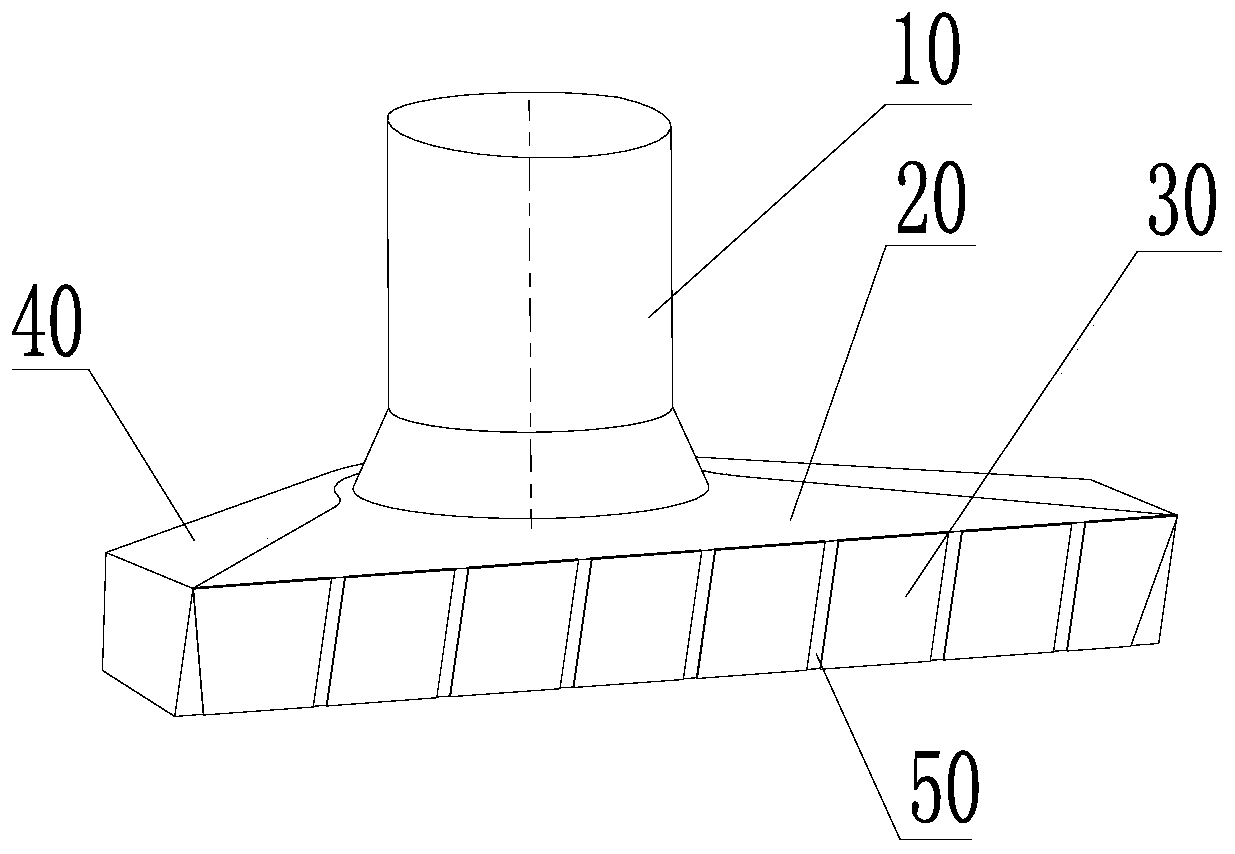

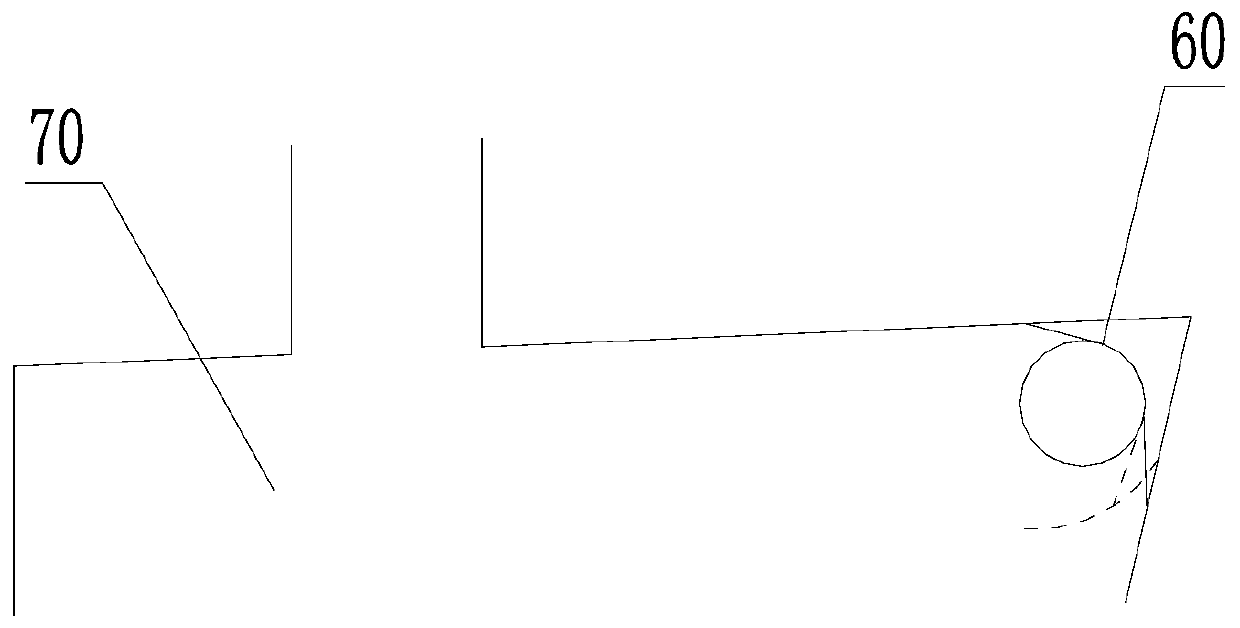

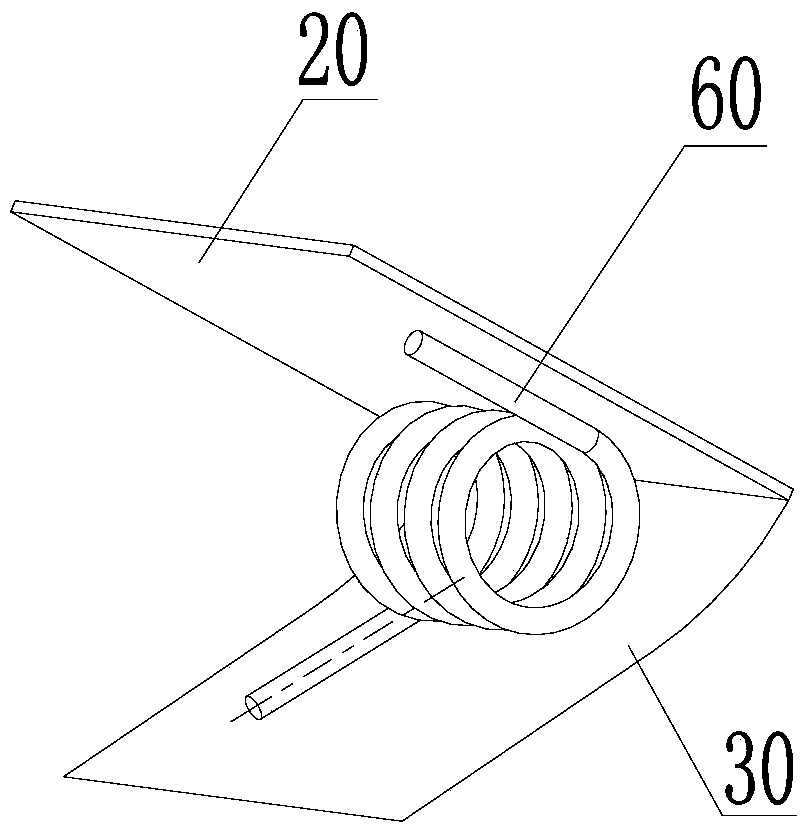

[0021] In order to overcome the defects in the prior art, the present invention provides a suction nozzle, which includes a suction pipe and a suction nozzle body, the suction nozzle body has a suction nozzle inner chamber communicated with the suction pipe, and the suction nozzle body includes a suction nozzle body The nozzle top plate, the nozzle front baffle and the nozzle seat, the nozzle front baffle includes a plurality of front baffle units, two adjacent front baffle units are connected by flexible components.

[0022] According to the technical solution of the present invention, the front baffle of the suction nozzle will not be rolled up as a whole, thereby ensuring that the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com