High-strength vibration-resistant building wall connecting framework

A building wall, high-strength technology, applied in building components, building structures, buildings, etc., can solve the requirement that the bulk density of the wall is not high enough to be light, the high cost of the wall is not conducive to promotion and energy saving, and the surface flatness is not easy. control and other issues, to achieve the effect of good protection, increased stability, and avoidance of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with specific embodiments.

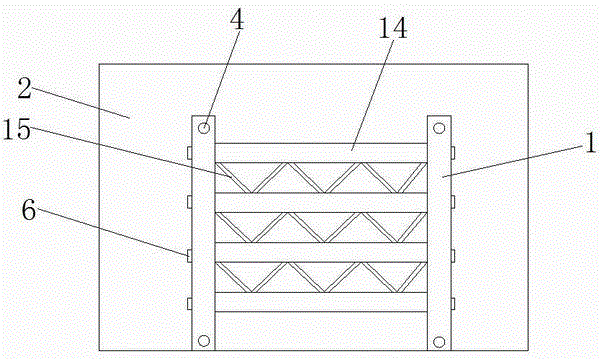

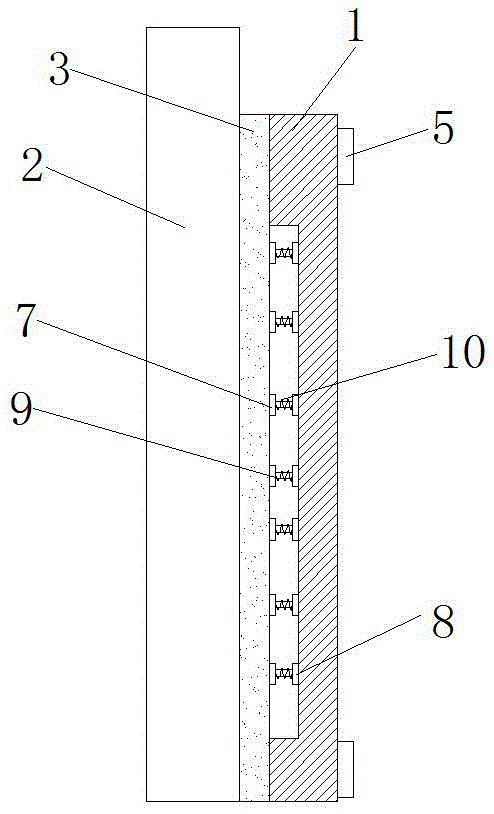

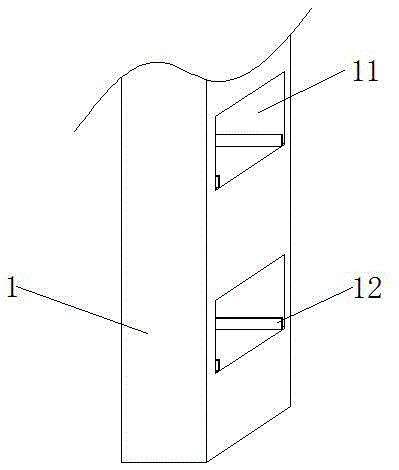

[0019] refer to Figure 1-4 , a high-strength anti-seismic building wall connection structure proposed by the present invention, comprising two fixed plates 1, one side of the fixed plate 1 is provided with a shock absorbing plate 3, the shock force generated during vibration can be reduced by the shock absorbing plate 3, Each fixed plate 1 is provided with a first screw hole 4 which is symmetrical up and down, and a first locking device 5 is inserted inside each first screw hole 4, and the fixed plate 1 passes through the first locking device 5 and The wall 2 is connected, and the shock absorbing plate 3 is located between the wall 2 and the fixed plate 1. The shock absorbing plate 3 is made of EVA material with double-sided glue, and the shock absorbing plate 3 and the wall 2 can be fixed by glue. The plate 1 is connected stably. By connecting the first locking device 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com