Rolling bearing unit with encoder for supporting wheel

A coding device and rolling bearing technology, applied in wheel bearings, rolling contact bearings, bearing components, etc., can solve the problems of density deviation, which is not conducive to ensuring the reliability of rotation speed detection, and achieve the effect of ensuring reliability and preventing strain deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

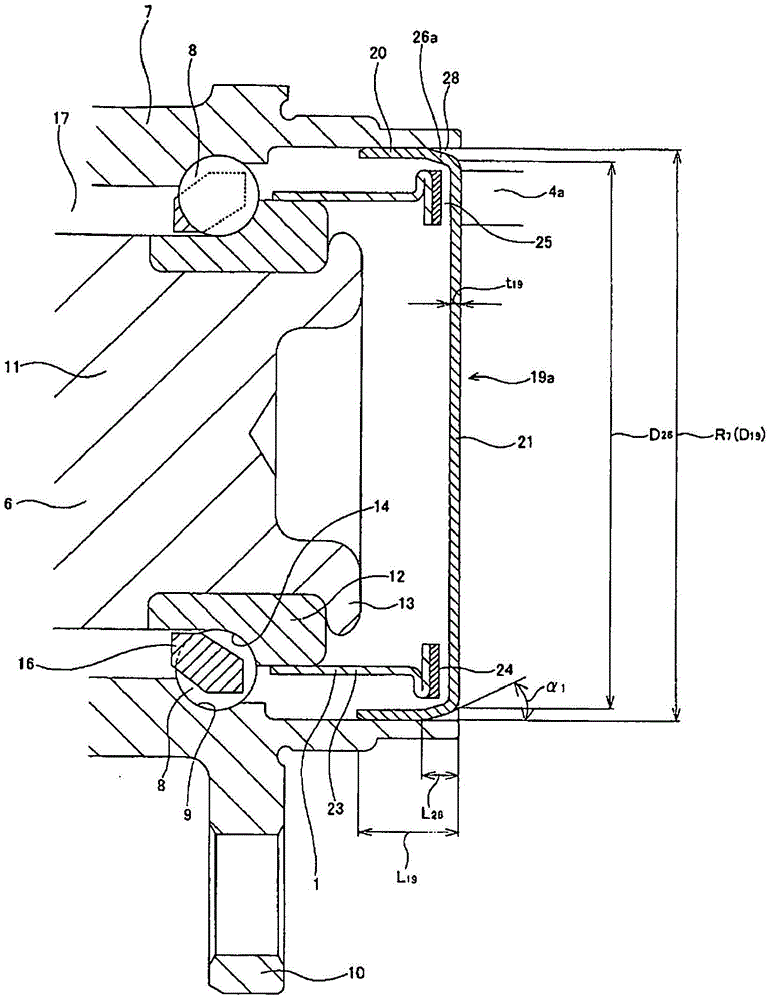

[0068] An example of a test conducted to confirm the effects of the present invention will be described below. In the test, using Figure 5 Cover 19c of the third example shown. Cover 19c with thickness dimension t 19 Made of 0.6mm SUS304 material. The outer diameter dimension D of the cover 19c 19 57mm, axial length L 19 7.8mm, the value of the interference (the inner diameter of the axially inner end of the outer ring 7 and the outer diameter D of the cover 19c 19 The absolute value of the difference) is 0.18mm (180μm).

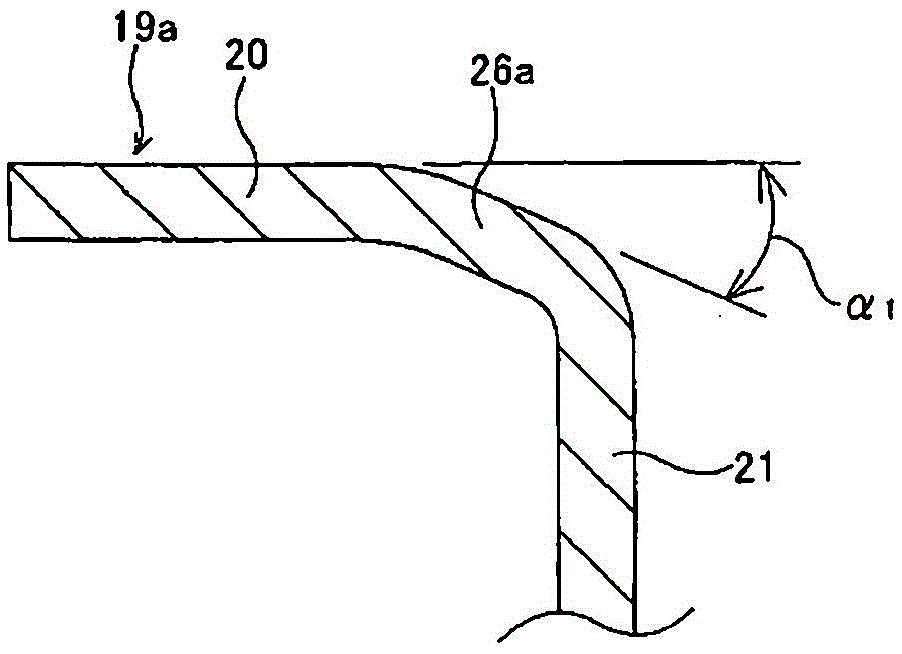

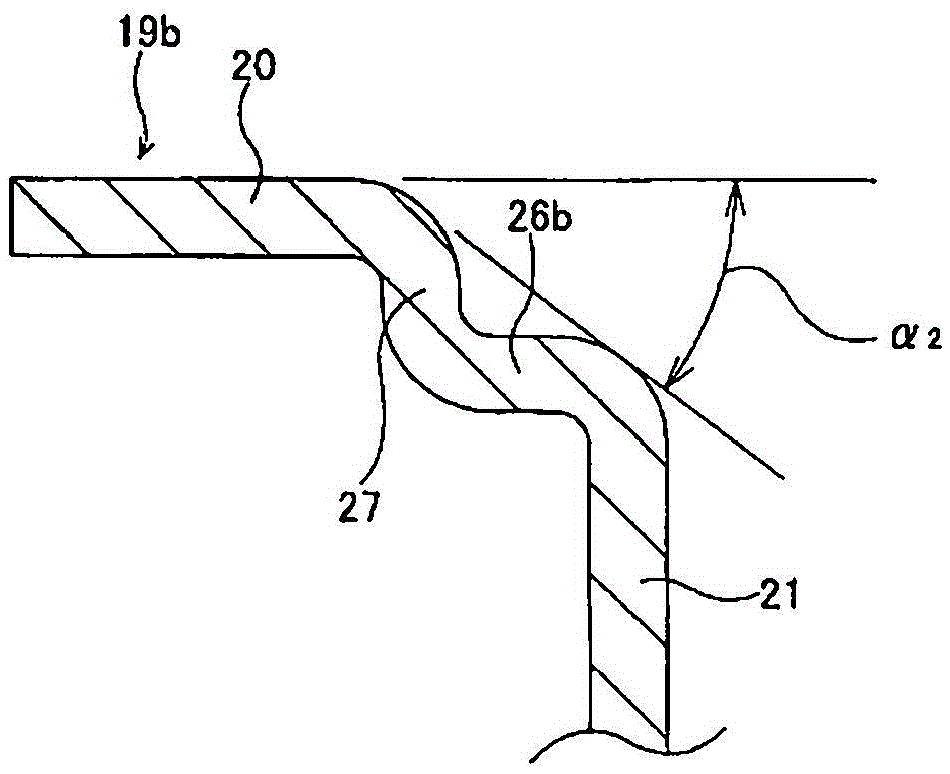

[0069] Further, the cap 19c is provided with a partial conical convex portion with an axial dimension of 2.2 mm and an inclination angle α of approximately 20 degrees. The cylindrical portion 20 of the cap 19c is fitted into the axially inner end portion of the outer ring 7 . In this state, the predetermined position near the outer diameter of the flat plate portion is 0, and the amount of deformation of the portion of the flat plate portion 21 facin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com