Resistive sensor array test circuit based on two-wire system voltage feedback

A technology of resistive sensor and voltage feedback, which is applied in the field of sensors, can solve the problems of destroying the ideal isolation feedback condition of the test circuit, the influence of the test accuracy of the resistive sensor array, and the increase of the measurement error of the resistance value of the tested unit, etc., to achieve the expansion of the resistance value range, eliminate the interference of space electromagnetic noise, and eliminate the effect of crosstalk error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

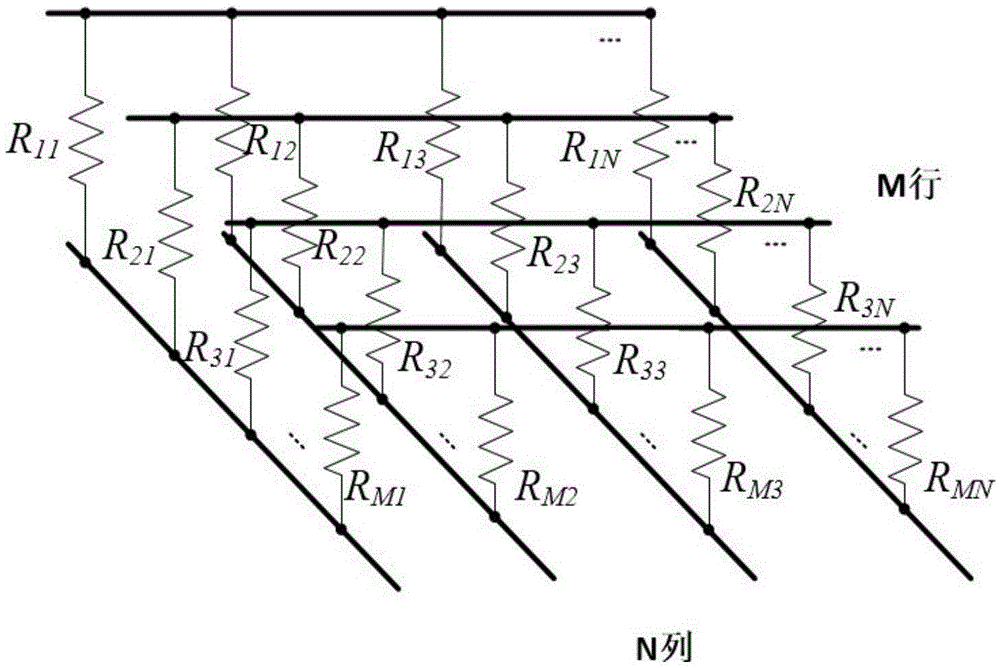

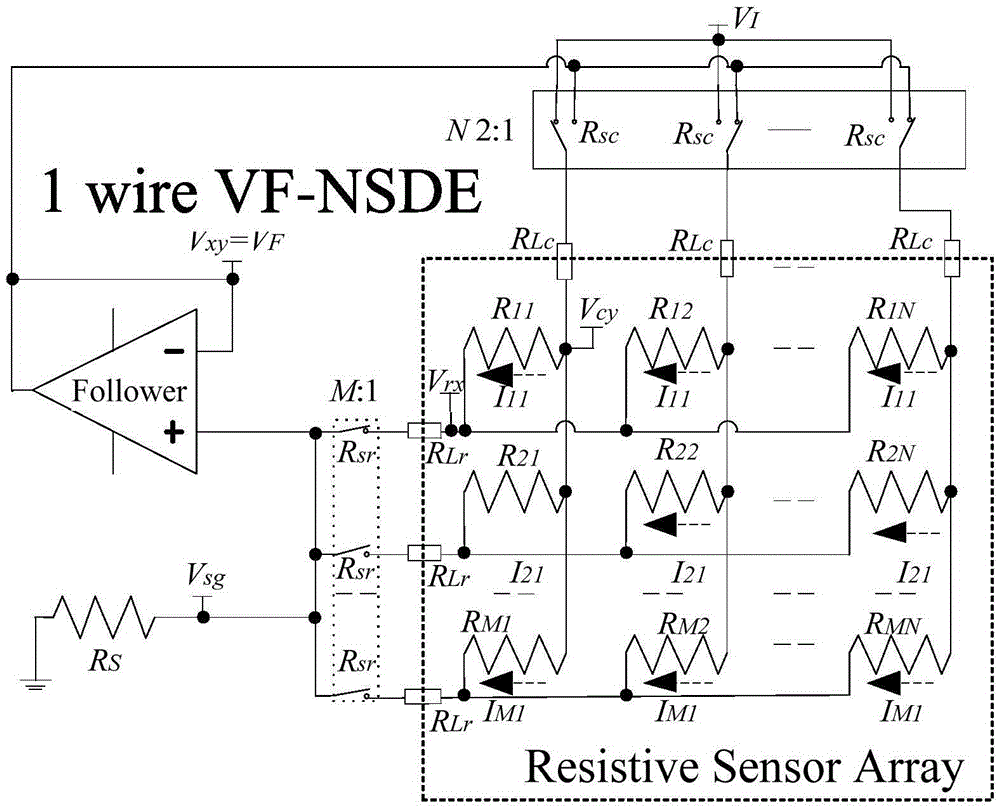

[0025] figure 2 Shows a typical voltage feedback method test circuit for a resistive sensor array sharing row and column lines, image 3 It is the equivalent diagram of the test principle of the test circuit. The current unit under test R in the figure xy R in an M×N shared row and column resistive sensor array 11 . In this circuit, there is only one connecting wire between each row line or column line of the array and the test circuit, and the sampling resistor R s There is an equal-current M select-one multi-way switch indirectly with the row line.

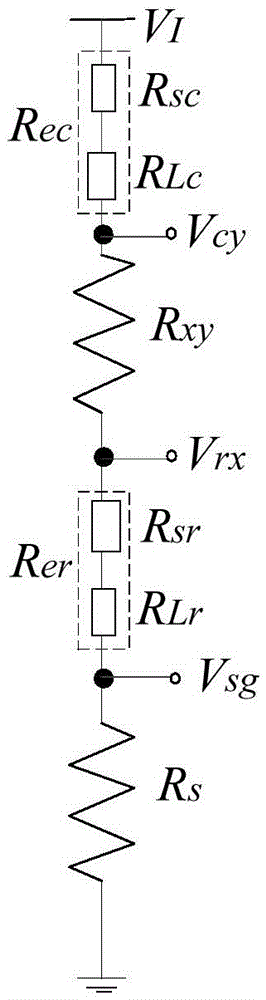

[0026] Under the ideal working condition of the test circuit, the channel on-resistance R sc , the cumulative resistance R of the lead resistance of the drive connection line and the contact resistance of the connector Lc is ignored so that R xy The voltage of the column line V cy equal to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com