Main busbar lapping device and method of low-voltage distribution cabinet

A busbar overlapping and power distribution cabinet technology, which is applied in the directions of busbar/line layout, substation/switch layout details, electrical components, etc., can solve problems affecting production efficiency, packaging and transportation quality, and long installation time, so as to improve packaging The effect of transportation quality, convenient combination of cabinets and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

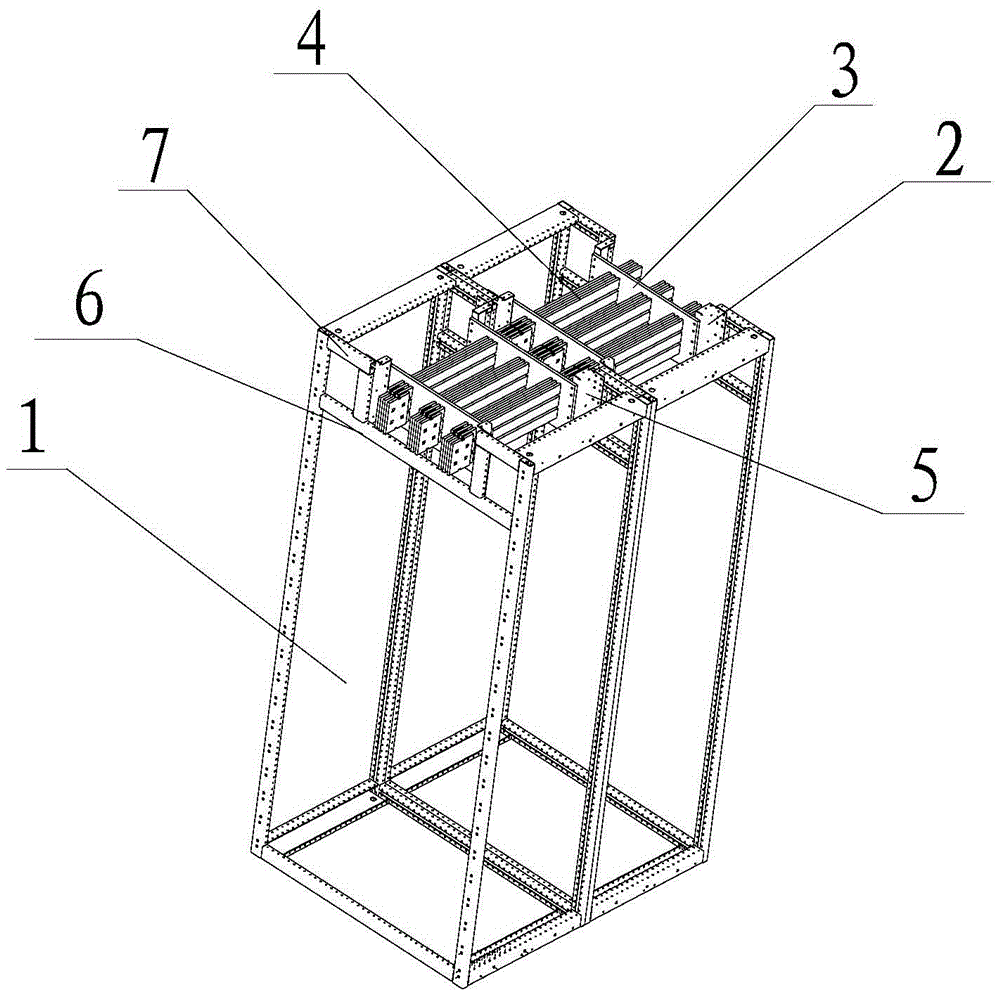

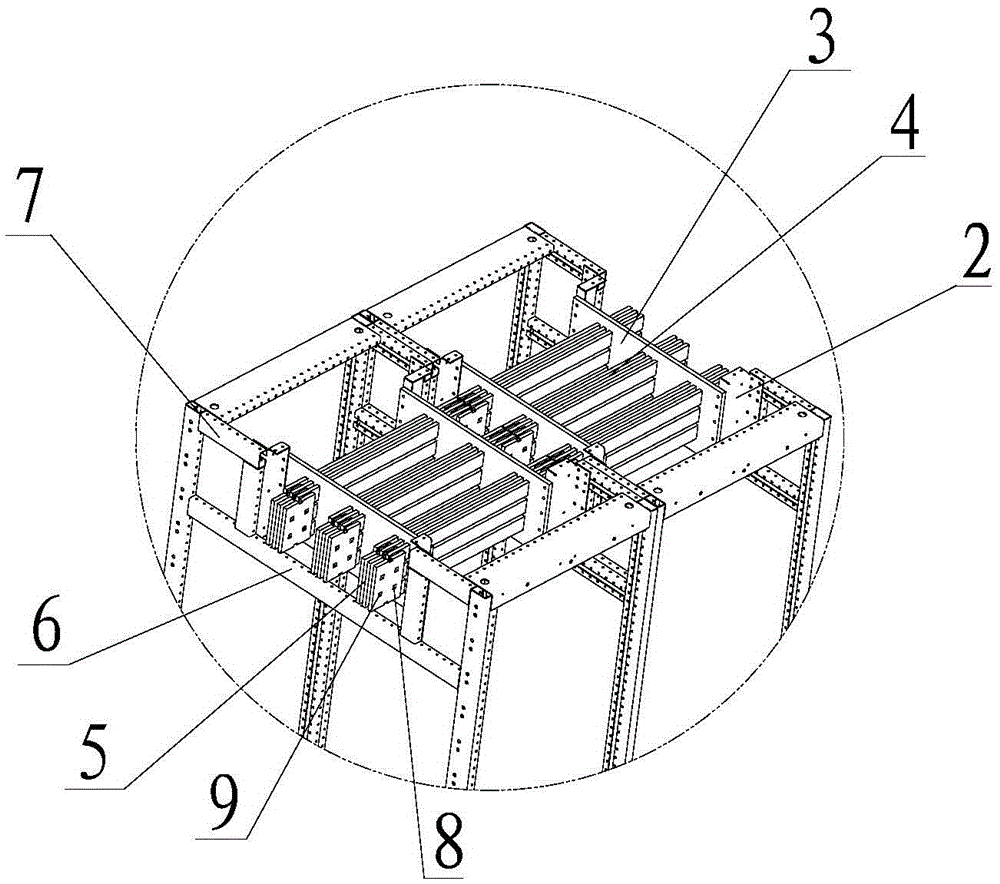

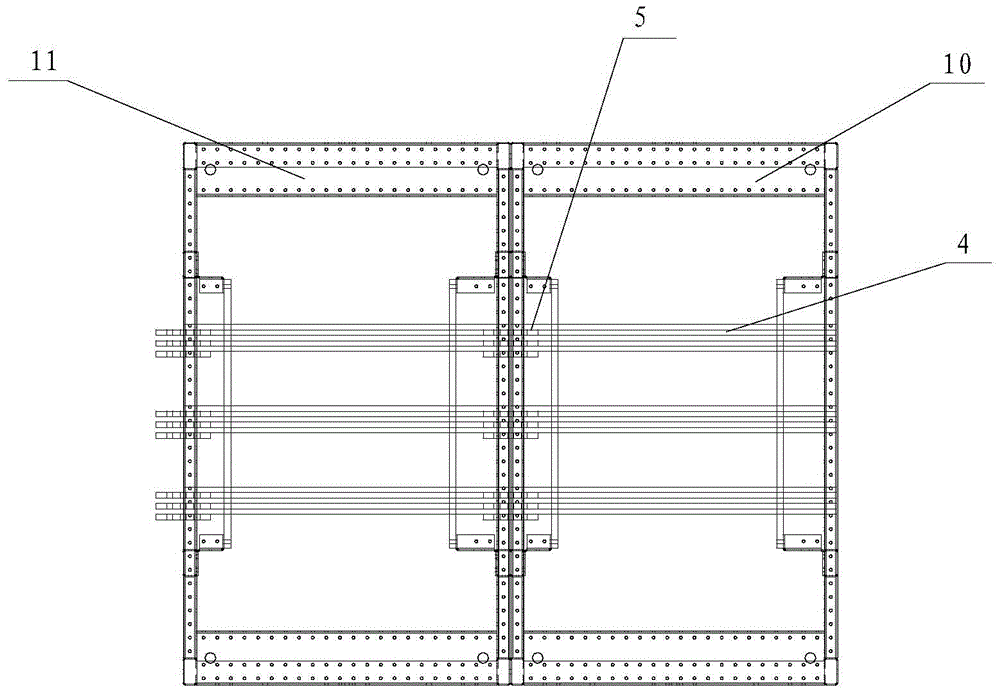

[0021] The structure of this embodiment is as Figure 1-Figure 4 As shown, the main busbar lapping device of the low-voltage power distribution cabinet includes two main frames 1 and the main busbar 4 installed on the top of the main frame. Horizontal support rods 6 are symmetrically arranged on both sides of the top, and the two ends of the support rods 6 near the main frame 1 are provided with a fixed plate 2 perpendicular to the support rods 6, and one side of the fixed plate 2 is in the same plane as the surface of the support rods 6. The other side of the plate 2 extends into the main frame 1, the fixed plate 2 is connected to the main frame 1 through the fixed rod 7, the other side of the fixed plate 2 is connected to the epoxy resin plate 3, and the main busbar is passed through the epoxy resin plate 3 4. The end face of the main busbar 4 is fixedly overlapped with the connecting row 5 . The outer side of the overlapping connecting row 5 protrudes from the plane where ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com