Inspection method and inspection line for tyres

A detection method and detection line technology, applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as interference with detection machine operations, underestimation of tires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

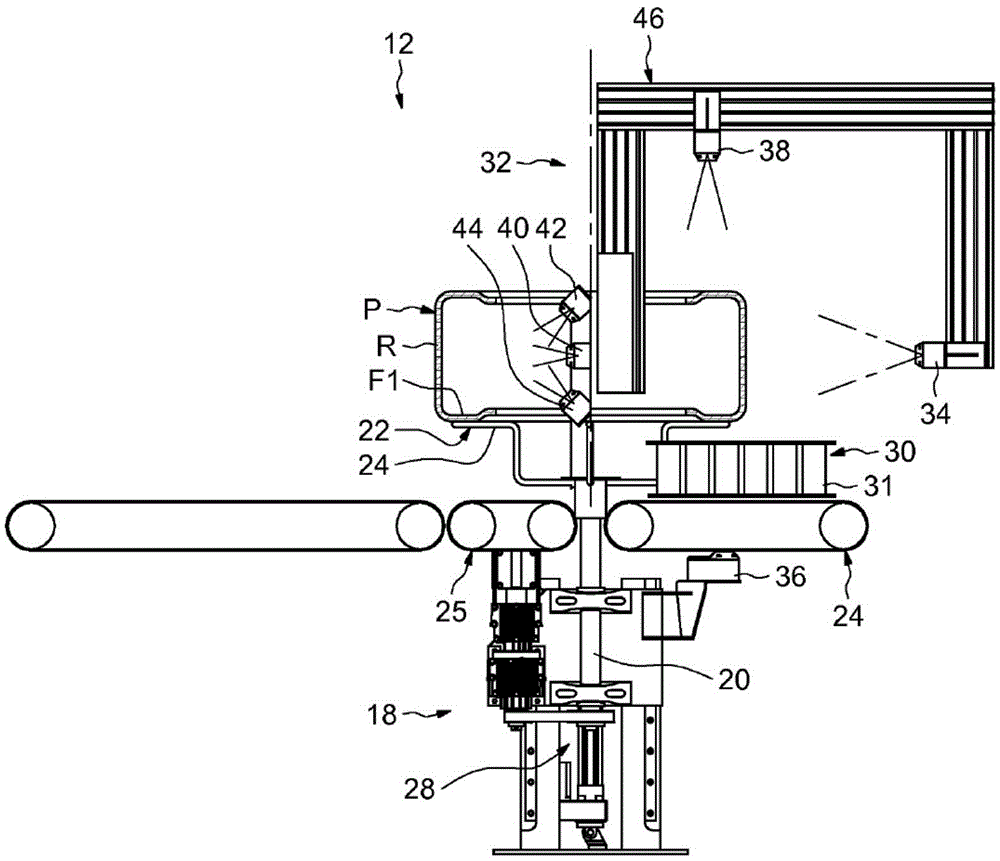

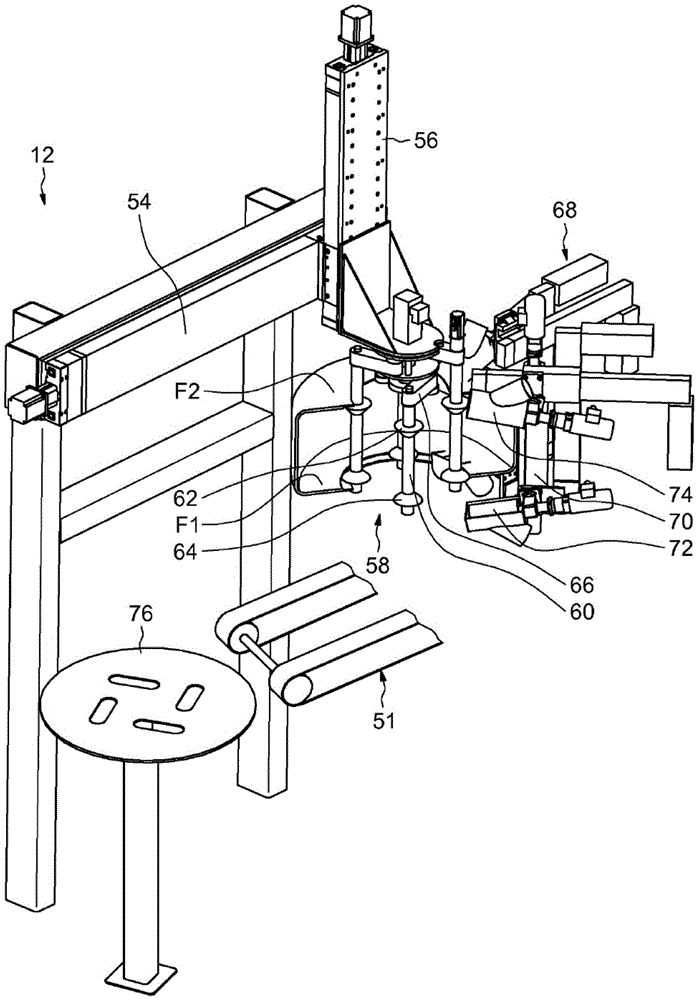

[0031] The following description relates to a tire P to be tested, comprising a peripheral tread R, sidewalls F1 and F1 , and annular beads B1 and B2 terminating the inner edges of these sidewalls.

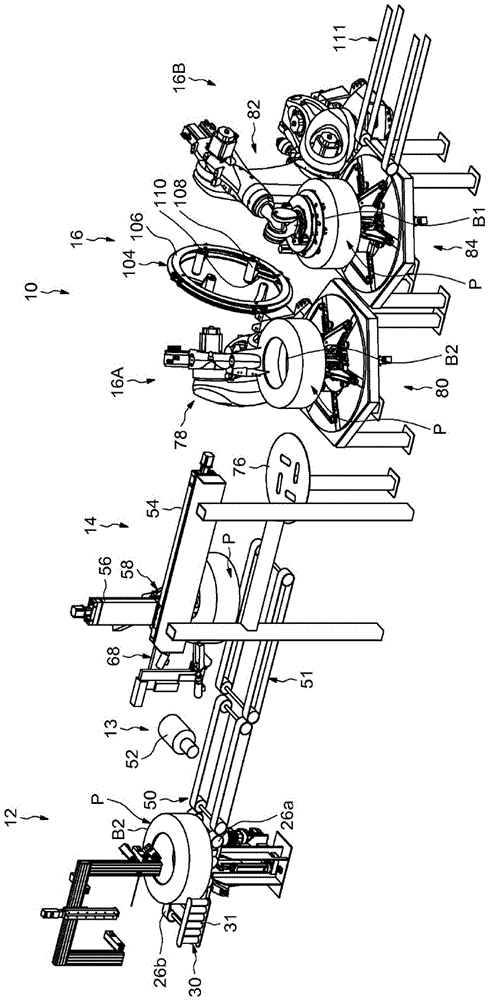

[0032] figure 1 A test line 10 for testing a tire P is shown in a general manner, said test line 10 comprising in turn a macro test station 12 for carrying out the first test sequence, a selection station 13, an intermediate brushing station 14, and a micro test station 16 (The microscopic inspection station 16 is used to carry out the second inspection sequence if the tire is received at the selected station).

[0033] Such as figure 1 and figure 2 As shown in more detail in , the macro inspection station 12 includes driving means 18 for rotating the tire P, and these means include a vertical rotating shaft 20, the upper end of which is equipped with, for example, four wheels arranged at 90°. The four-armed support 22 consists of radial support arms 24 that provide a horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com