Rapid leveling method of shoe edges

A leveling and fast technology, applied in the direction of shoemaking machinery, footwear, clothing, etc., can solve the problems of slow leveling speed and high work intensity of manual leveling, and achieve the effect of ensuring quality, improving leveling efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

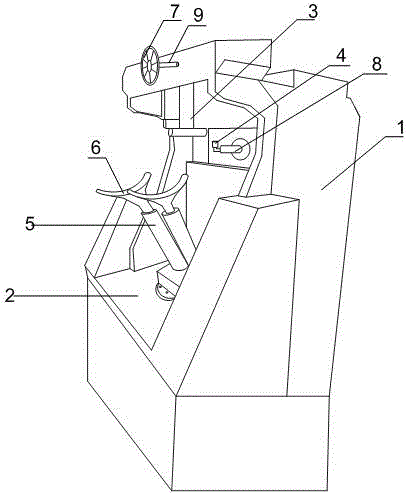

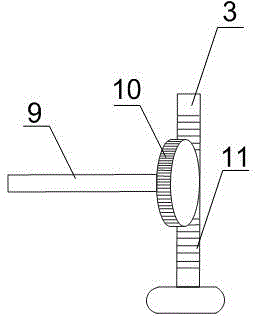

[0020] Such as figure 1 As shown, the present invention first sets the workbench on the supporting frame of the leveling device to facilitate the picking and placing of the shoes to be processed. The placement mechanism can move on the workbench through gear engagement. After the shoes are placed on the placement mechanism, the placement mechanism The leveling wheel is close, and the sliding lower pressure rod moves downward to compress the shoes. The lower pressure rod is made of soft plastic, which can effectively avoid crushing the sole or upper of the shoe while ensuring the compression of the shoe; After the shoes are fixed, the leveling wheel starts to rotate quickly left and right on the support frame under the drive of the motor, and performs a leveling process on the edge of the shoe; the leveling device includes a support frame 1, a placement mechanism, a lower pressure rod 3 and a leveling wheel 4 , the support frame 1 is provided with a workbench 2, the placement m...

Embodiment 2

[0023] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the placement mechanism includes two placement rods 5 arranged at intervals. There is a U-shaped joint 6; according to the difference in size and type of shoes, two placing bars 5 are arranged at intervals, and a U-shaped joint 6 is installed on the placing bar 5, and its shape is similar to that of the shoes, so that various Model shoes, in order to adjust the position of the shoes during processing, and speed up the progress of shoe edge leveling. The U-shaped storage platform is conducive to the leveling of shoes, and avoids displacement or falling out when the shoes are in contact with the leveling wheel 4. Mechanism, which affects the leveling efficiency; the distance between the two placing rods 5 is 22-28cm, the size of the shoes is roughly within 35-45 yards, and the unit of measurement converted into length is 20-30cm, and the distance is set at 22-28cm 28㎝, which can ensure that all type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com