Comprehensive separation system for ore

A comprehensive separation and ore technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of insufficient recovery of useful particles, complicated operation, and many consumables, and achieve good environmental protection effect and high separation accuracy , Improve the effect of sorting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

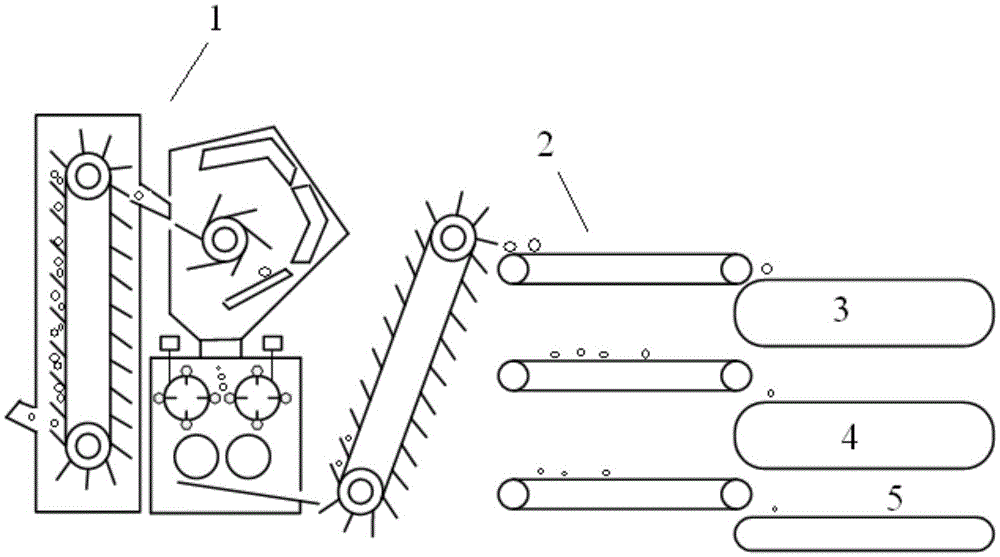

[0023] Such as figure 1 As shown, the comprehensive ore sorting system of the present invention includes a preliminary processing unit 1, a screening unit 2, a primary sorting unit 3, a secondary sorting unit 4, a third sorting unit 5, and a control unit.

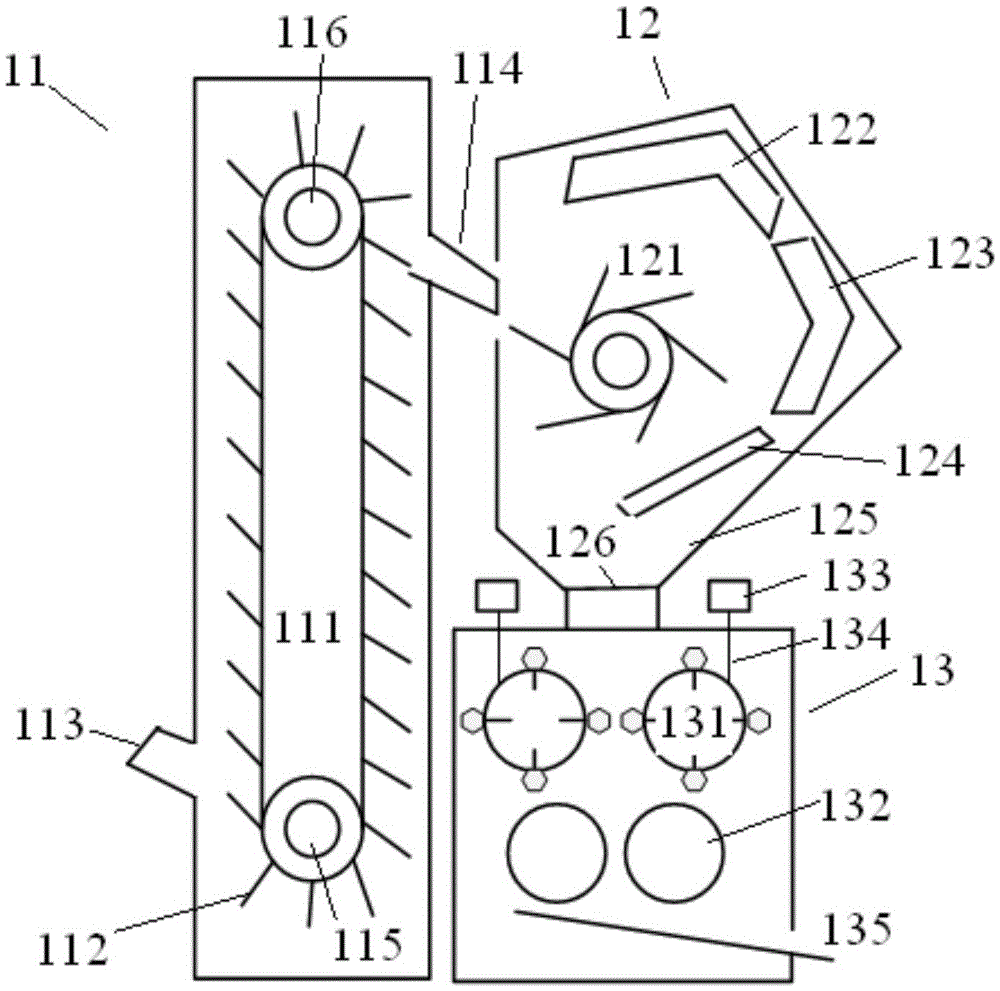

[0024] Among them, the primary processing part 1 is used for primary crushing processing of the ore, which ensures a certain processing effect. The preliminary processing unit 11 includes an elevator 11 , an impact crushing chamber 12 , and a rolling crushing chamber 13 . The elevator includes a conveyor belt 111, a plurality of hoppers 112 arranged on the conveyor belt, a raw material inlet 113 arranged below the elevator, a raw material discharge outlet 114 arranged above the elevator, a driving wheel 115, a driven wheel 116, and a driving wheel 115. motor (not shown). The elevator drives the driving wheel and the driven wheel to rotate through the drive motor, so that the ore is picked up from the raw material inlet at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap