Dispersing water pipe for bottom box of magnetic separator

A magnetic separator and water pipe technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of wear, damage, and ore leakage at the bottom of the bottom box of the magnetic separator, so as to improve the contact surface and increase the affected area. Force area, mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

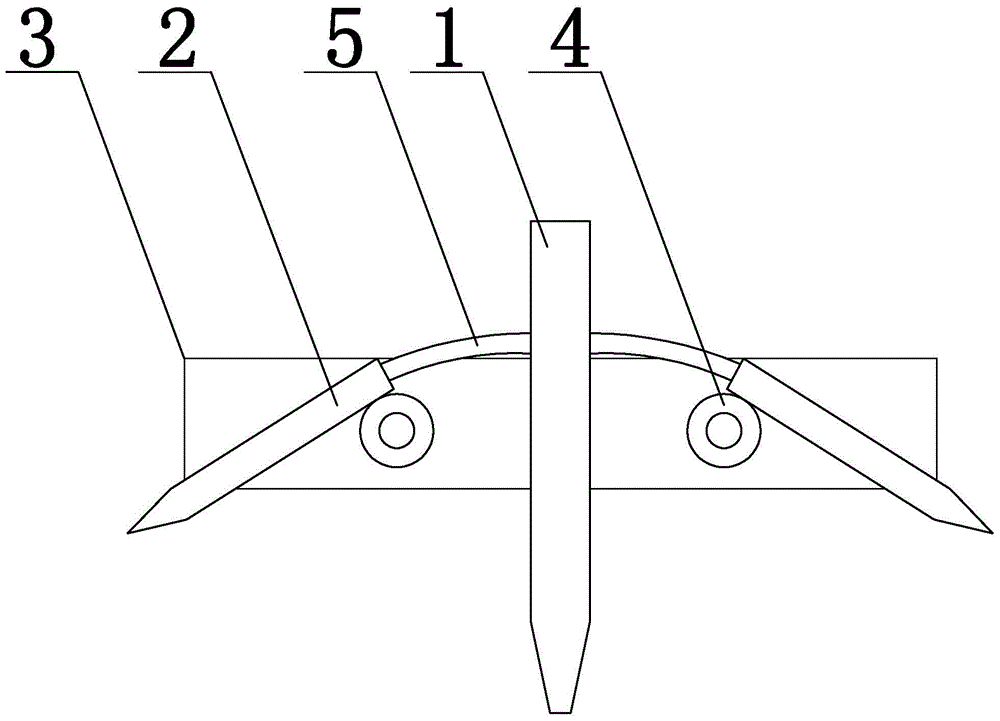

[0022] Embodiment 1: as figure 1 As shown, the flushing water pipe of the bottom box of the magnetic separator of the present invention comprises a magnetic separator flushing water pipe 1, and the two sides of the flushing water pipe 1 are respectively provided with a shunt water pipe 2, and the shunt water pipe 2 communicates with the ore flushing pipe 1, and the shunt The inner diameter of the water pipe 2 is half of the water pipe 1 for flushing ore.

Embodiment 2

[0023] Embodiment 2: On the basis of the structure described in Embodiment 1, the ore flushing water pipe 1 is provided with a base 3, the diversion water pipe 2 is hinged on the ore flushing water pipe 1 through the rotating shaft 4, and the diversion water pipe 2 is connected to the ore flushing through the hose 5 The water pipe 1 is provided with a flat shower head at the mouth of the ore flushing water pipe 1.

Embodiment 3

[0024] Embodiment 3: On the basis of the structure described in Embodiment 2, the outlet of the water diversion pipe 2 is provided with an adjustable nozzle for adjusting the flow rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com