Gluing conveying device for opening-closing piece outer plate assembly

A technology for conveying devices and opening and closing parts, which is applied in the field of conveying lines, can solve the problems of poor versatility, poor stability of the conveying process, and inaccurate conveying positions, and achieve the effects of preventing slipping, reasonable and compact position distribution, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

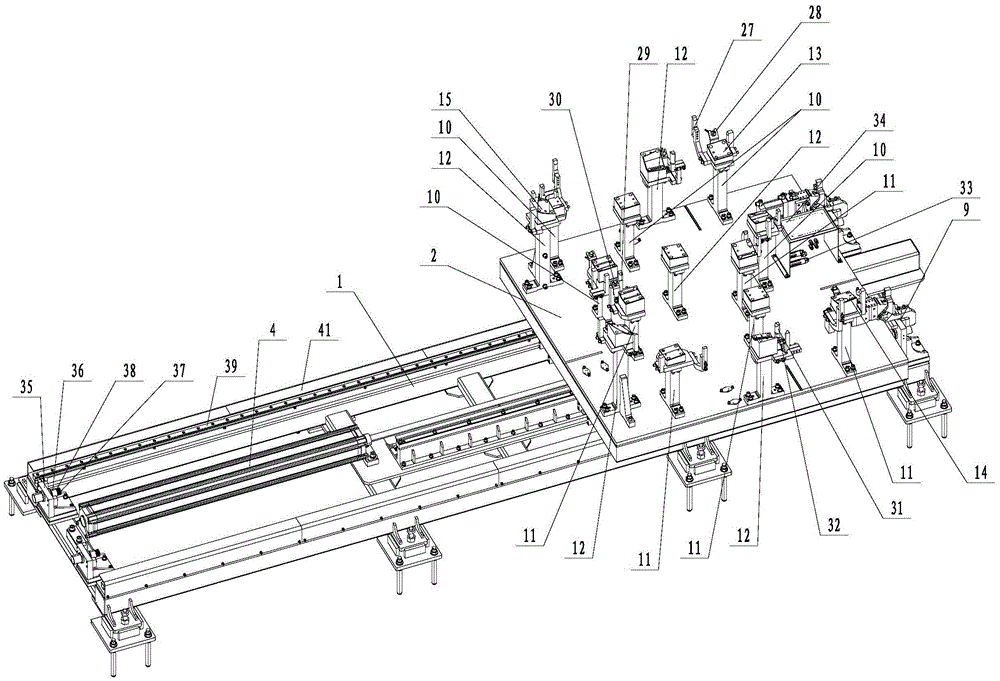

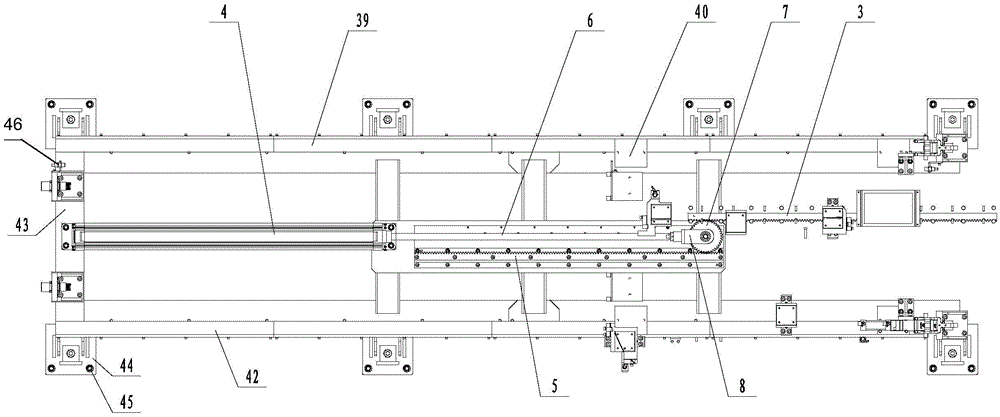

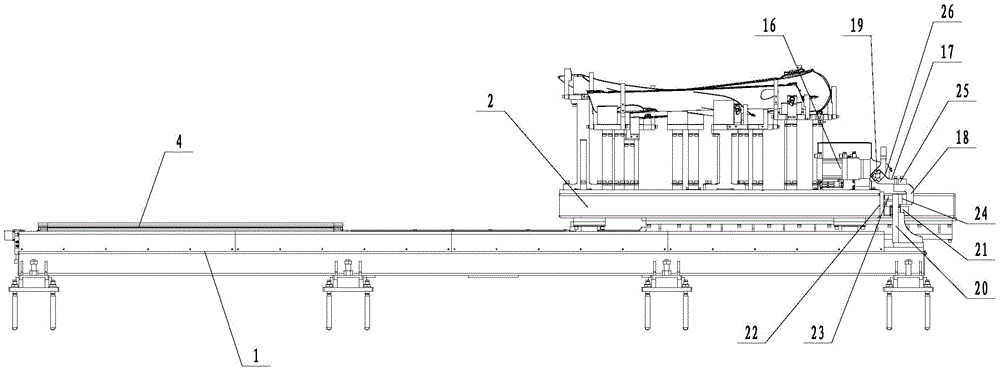

[0023] Embodiment: A glue coating conveying device for the outer plate assembly of the opening and closing parts (see the attached Figures 1 to 4), including a bracket 1, a support slide 2 that can be slidably installed on the bracket, a drive rack 3 is fastened to the lower end of the support slide, a drive piston cylinder 4, a guide rack 5 are installed on the bracket, and a drive piston cylinder telescopic rod 6 is connected with a driving gear 7, and the connecting position of the driving gear and the telescopic rod of the driving piston cylinder is connected with a mounting seat 8. The mounting seat is a U-shaped structure, and the driving gear is rotatably connected between the two side walls of the U-shaped mounting seat. The drive connection is between the drive rack and the guide rack. The clamping positioning mechanism 9 for positioning and supporting the slide table is installed on the support away from the end of the drive piston cylinder. The clamping positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com