Inverter Plasma Cutting Machine and Its Control Method in Arc Starting Stage

A technology of plasma cutting machine and inverter, which is applied in the fields of cutting and welding, which can solve the problems of reducing the success rate of arc striking, increasing the cost, and increasing the size of the cutting machine, so as to reduce costs, ensure stability and improve the success rate of arc striking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

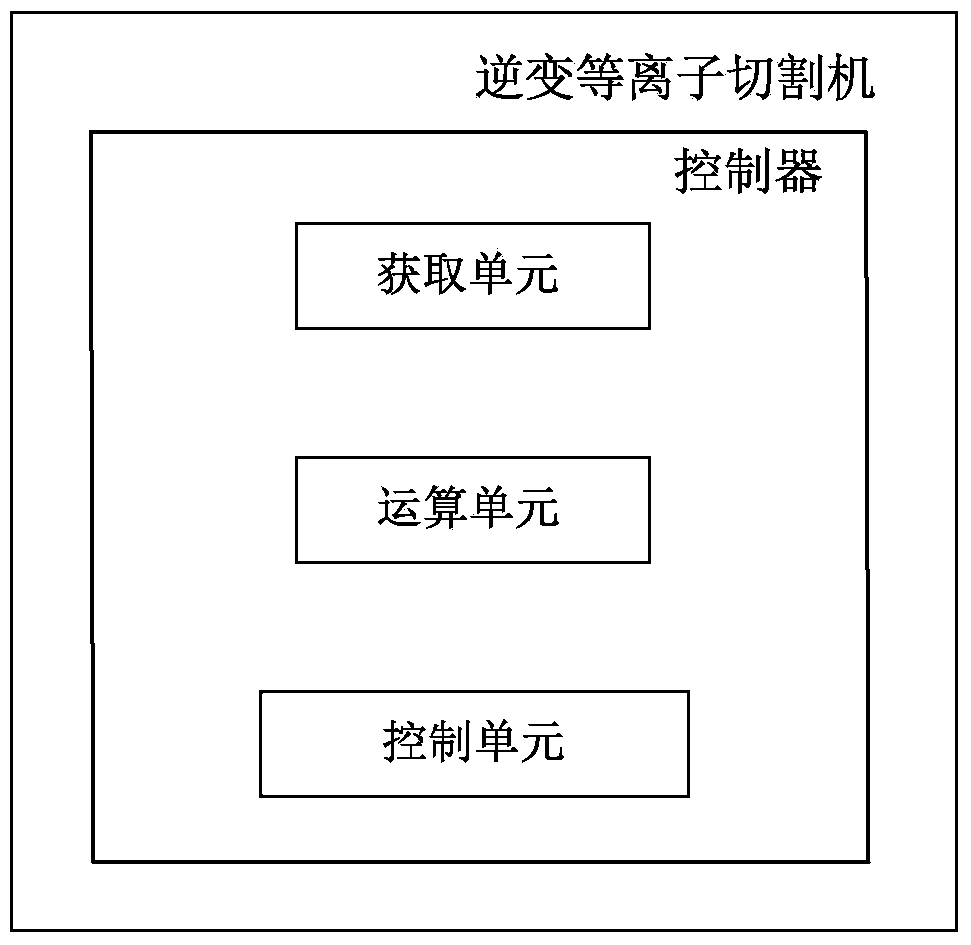

[0020] First, the hardware structure of the inverter plasma cutting machine according to the first embodiment of the present invention will be briefly described. The inverter plasma cutting machine includes a controller and a power switching device (IGBT), and the controller controls the power switching device through a driving circuit.

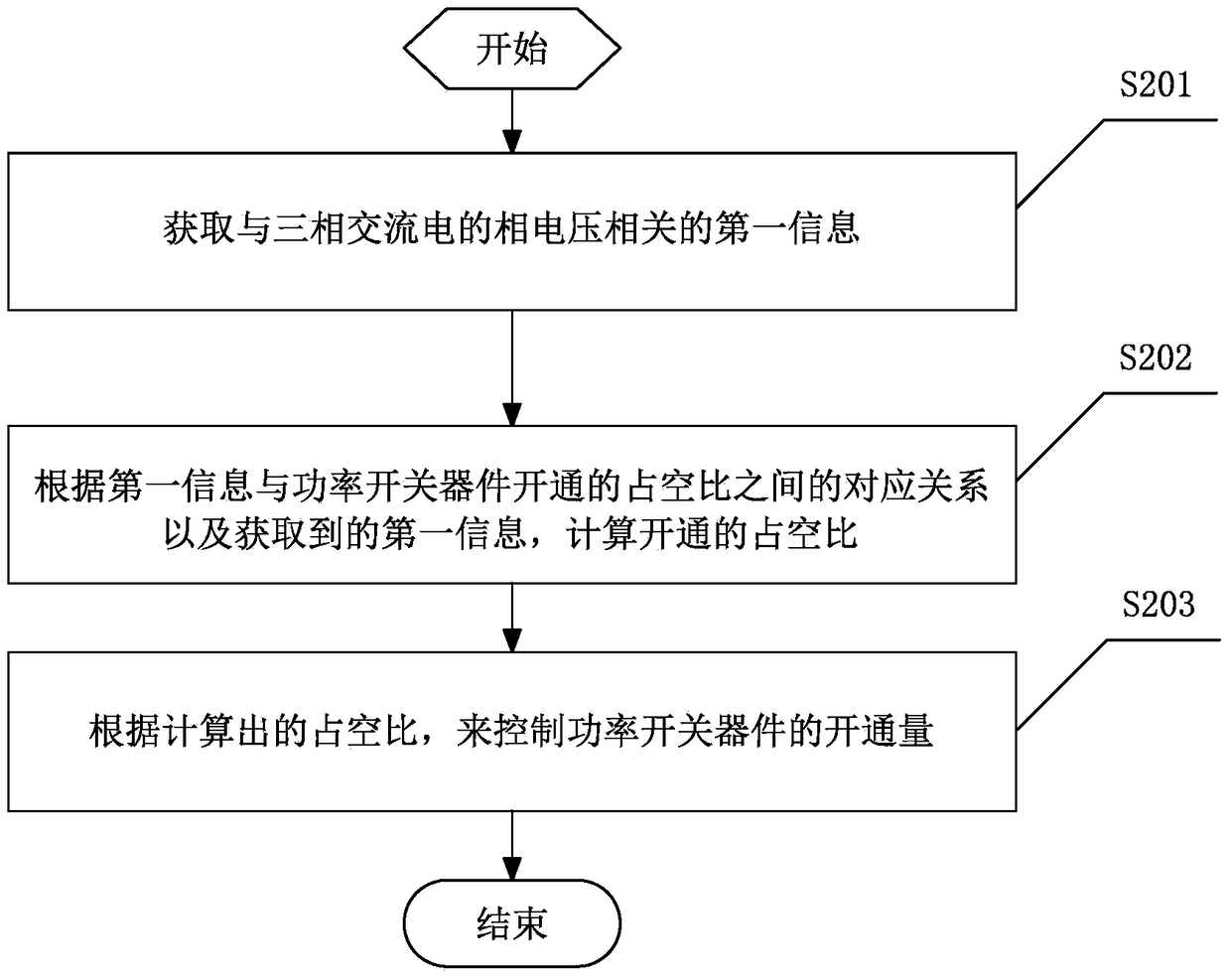

[0021] The inverter plasma cutting machine of this embodiment also includes a voltage detection circuit for detecting the phase voltage of the three-phase AC power supply. The output terminal of the voltage detection circuit is connected with the controller. The voltage detection circuit can detect the phase voltage between any two phases. As the structure of the voltage detection circuit, it can be implemented in the form of a known voltage transformer combined with a rectification and filtering circuit. In addition, the voltage detection circuit can also be implemented in the form of a known control power transformer combined with a recti...

no. 2 example

[0031] The second embodiment of the present invention is described below. First, the hardware structure of the inverter plasma cutting machine of the second embodiment will be described. Like the first embodiment, the inverter plasma cutting machine includes a controller and a power switching device (IGBT), and the controller controls the power switching device through a driving circuit. The difference from the first embodiment is that the inverter plasma cutting machine also includes an operation panel for inputting cutting current. The operation panel is connected with the controller.

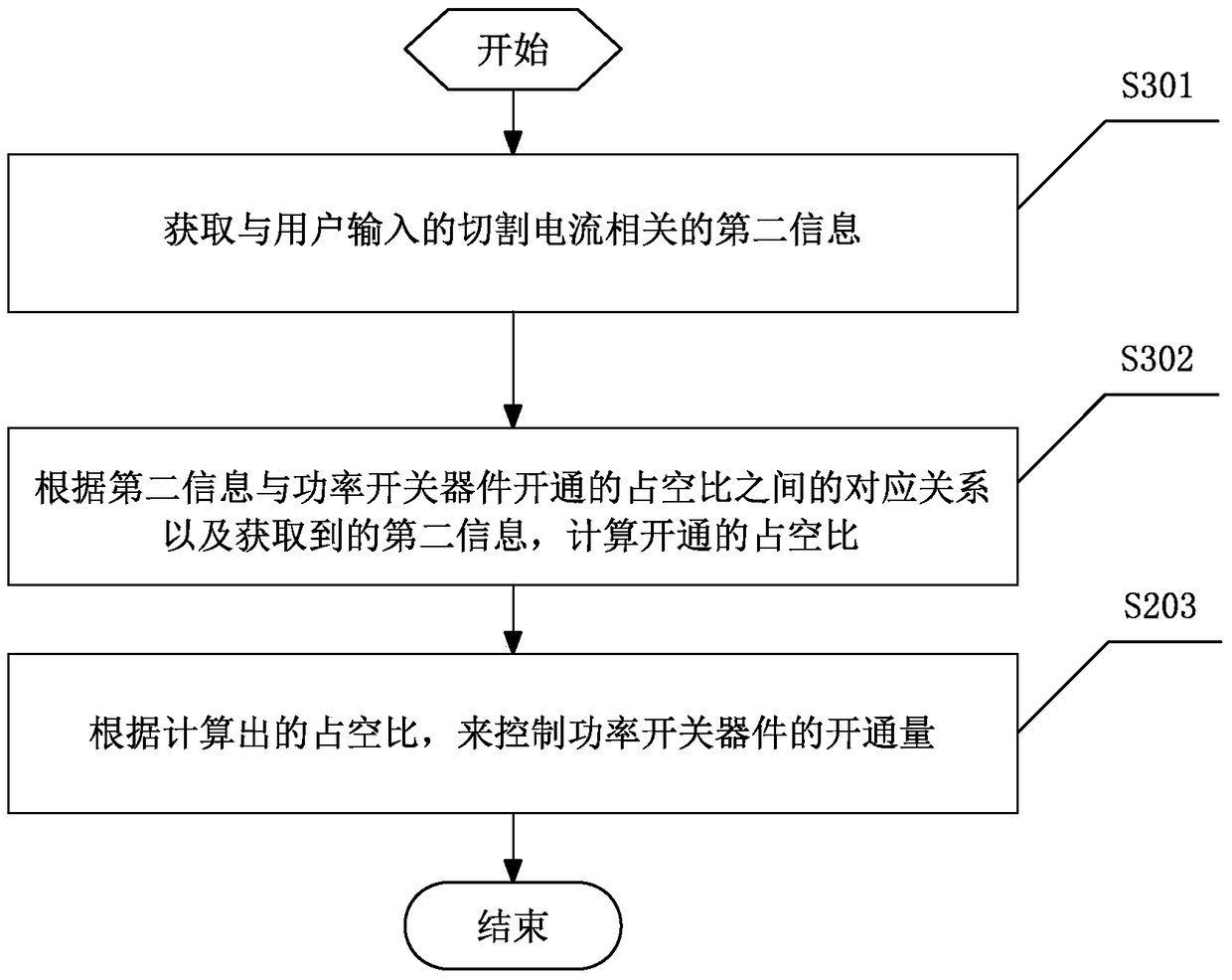

[0032] The software structure of the second embodiment is basically the same as that of the first embodiment (see figure 1 ), so the relevant description is omitted. It should be noted that, in this embodiment, the information related to the cutting condition is the second information related to the cutting current (also called preset current) input by the user through the operation panel...

no. 3 example

[0039] A third embodiment of the present invention is described below. First, the hardware structure of the inverter plasma cutting machine of the third embodiment will be described. Like the first embodiment, the inverter plasma cutting machine includes a controller and a power switching device (IGBT), and the controller controls the power switching device through a driving circuit. The difference from the first embodiment is that the inverter plasma cutting machine also includes a pressure sensor for detecting the pressure of the compressed air used for cutting. The pressure sensor is connected with the controller.

[0040] The software structure of the third embodiment is basically the same as that of the first embodiment (see figure 1 ), so the relevant description is omitted. It should be noted that, in this embodiment, the information related to the cutting condition is the third information related to the pressure of the compressed air for cutting.

[0041] Next, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com