A pressing mechanism for micro components

A technology of pressing mechanism and components, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of finished products not meeting requirements, affecting the quality of finished products, uncontrollable positions, etc., and achieving the effects of low cost, simple operation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

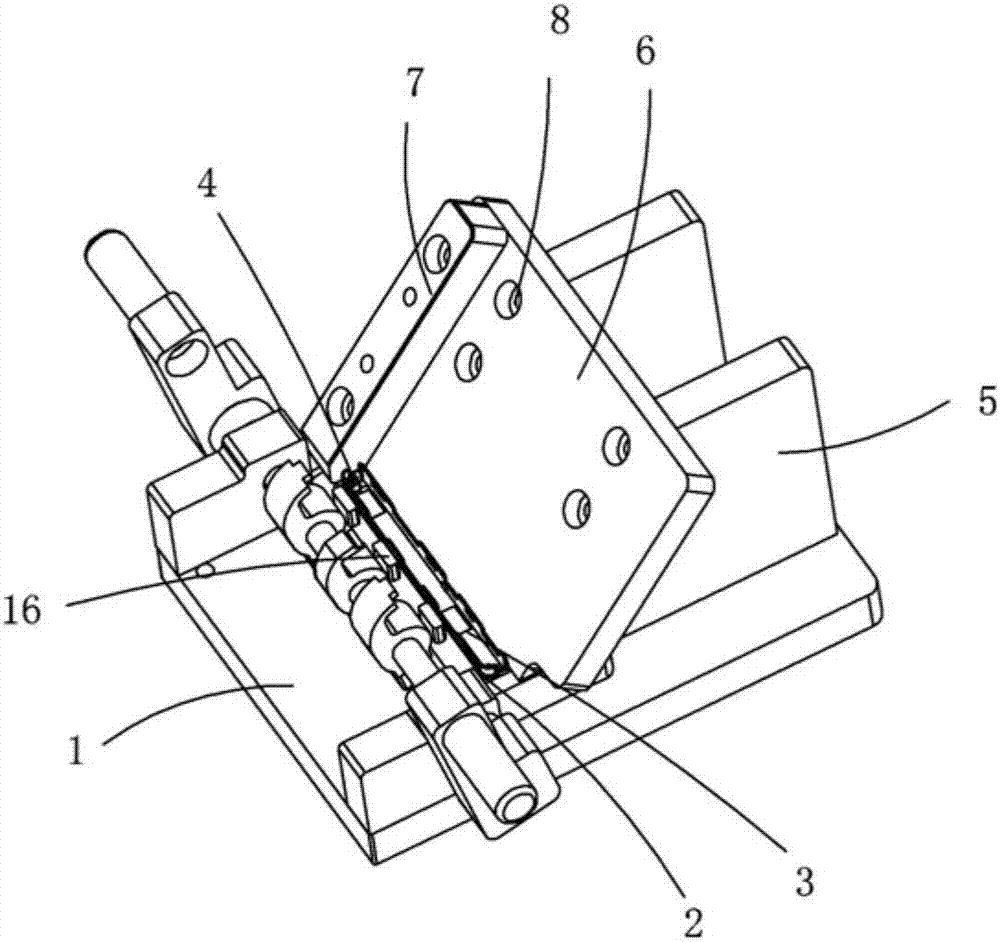

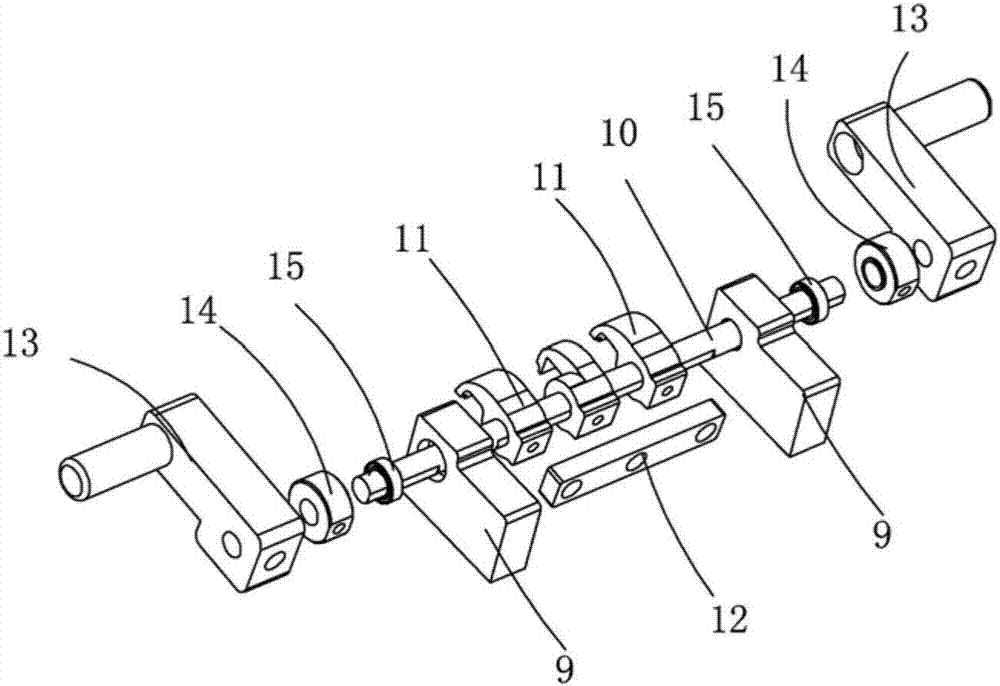

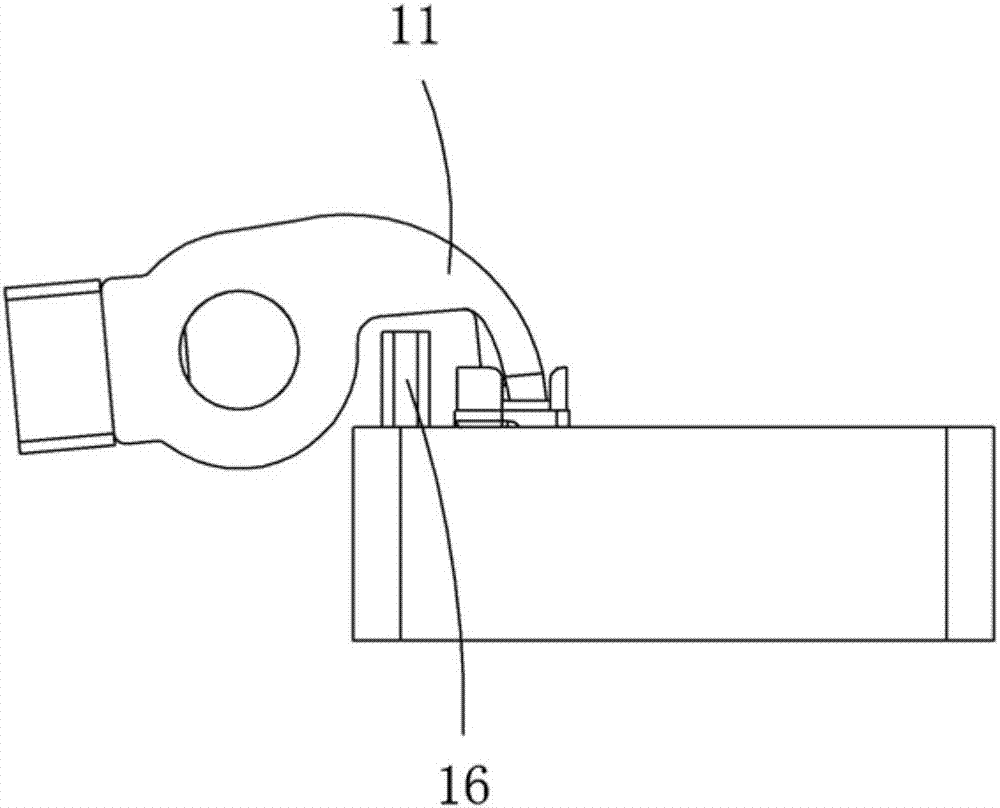

[0023] Examples, see attached Figure 1~3 , a pressing mechanism for micro-components, including a base 1, a product positioning seat 2 is arranged on the base, a product 3 is positioned in the product positioning seat, and multiple groups of micro-components 4 are placed in the product. The base is equipped with a placement guide plate 6 through the support plate 5, and the placement guide plate is obliquely installed above the base, and the rear end of the product is resisted and positioned by placing the guide plate; the left end of the placement guide plate is screwed and fixedly installed with Positioning bar 7; the product is put into the product positioning seat along the placement guide plate, and the left end of the product is against the positioning bar; the support plate has two groups, and each set of support plates is provided with an inclined surface, which is placed on the guide plate An installation hole 8 is provided, through which the placement guide plate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com