Bamboo joint pile mold

A technology of bamboo piles and molds, which is applied in the direction of molds, etc., can solve the problems of waste of resources, inability to adjust the size and shape, and restrictions on the specifications of manufacturing square piles, and achieve the effects of easy removal, avoiding repeated investment, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

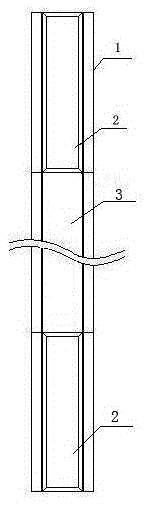

[0020] Such as figure 1 As shown, a bamboo pile mold of the present invention comprises an outer mold 1 and an inner mold installed in the outer mold 1, the inner mold 2 is installed in the outer mold 1, and the inner mold includes an inner mold slub 3 and an inner mold Detail 2, the inner mold slub 3 and the inner mold details are arranged in two intersections, and there is a bulge at the intersection of the inner mold slub 3 and the inner detail 2, and the length of each section of the inner mold 1 is 80-120cm, and the bulge The included angle is 110-160°, and the protrusion height is 5-15cm. The inner mold 1 is provided with a fixed support groove or connected with a support nut. Fix the inner mold inside the outer mold.

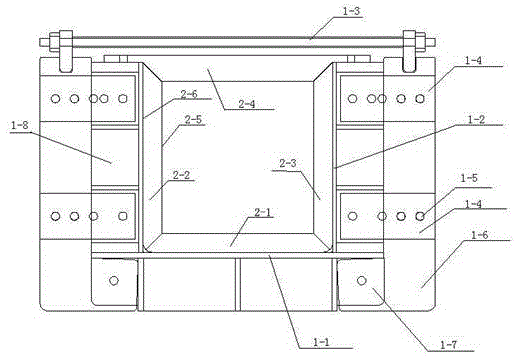

[0021] Such as figure 2 As shown, the outer mold is composed of a bottom formwork 1-1 and two left and right side formworks 1-2, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com