Slip-drop preventing fence of high platform

An anti-slip, high-platform technology, which is applied to stations, railway car body parts, roads, etc., can solve the problems of safety hazards for passengers getting on and off the train, and large gaps at the joints of carriages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

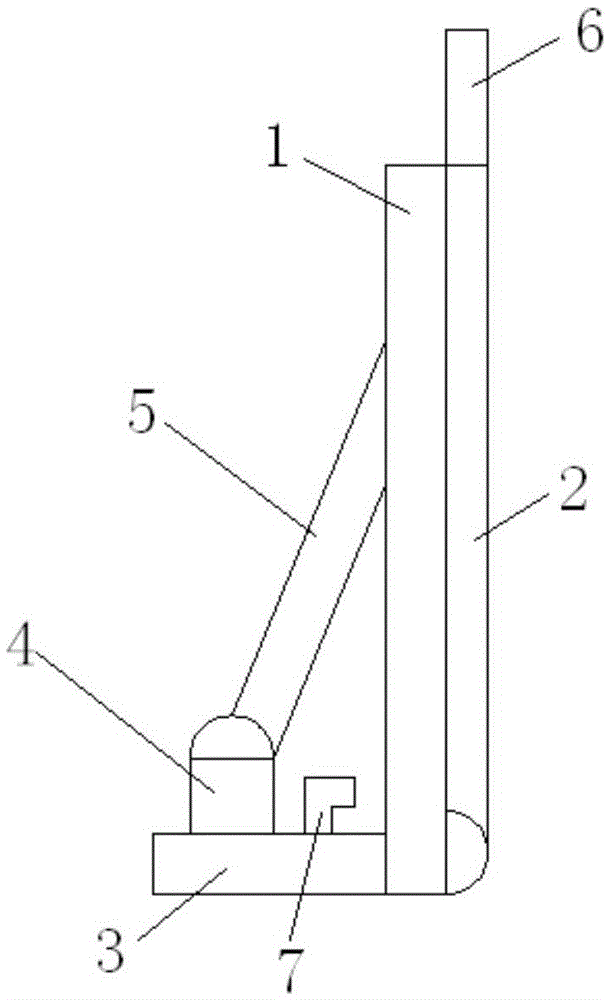

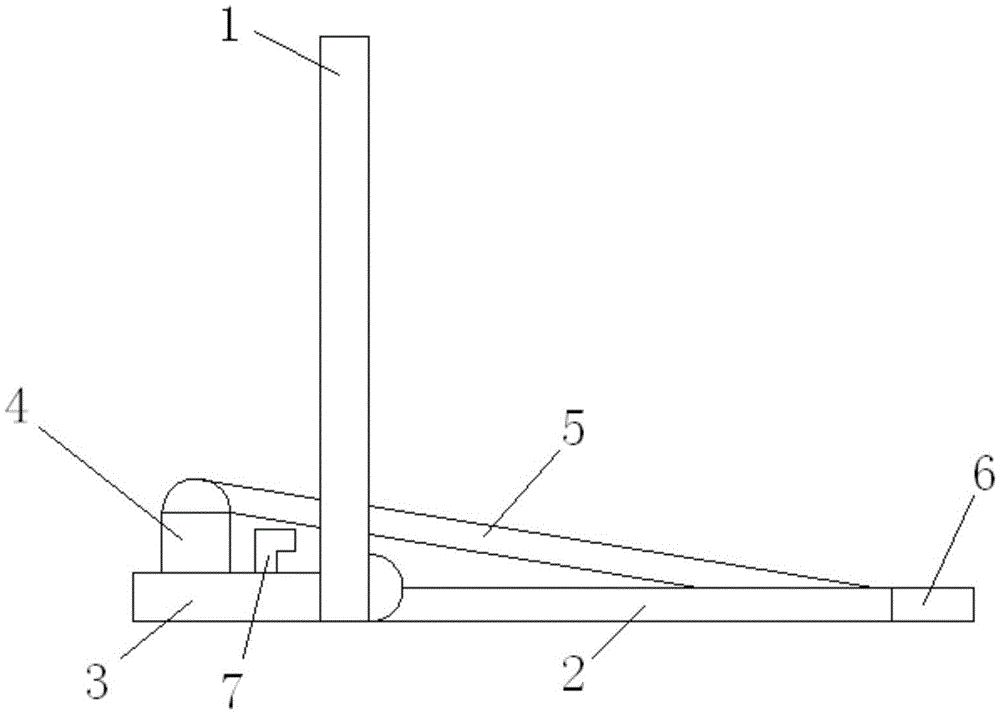

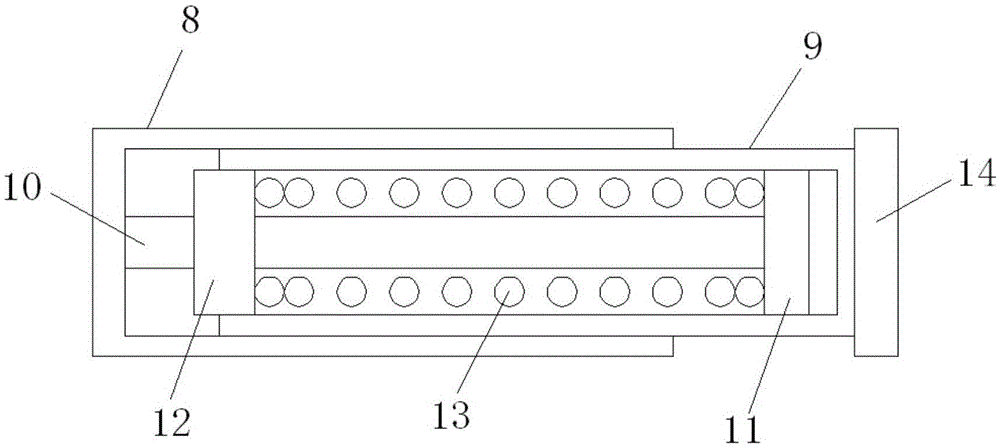

[0020] like figure 1 and figure 2 The anti-slip grid of a high platform is shown, including a grid support 1, a grid 2, a gap filling mechanism 6, a support platform 3, a hydraulic cylinder 5, an induction sensor 7 and an electromagnetic device, and the grid 2 is located on the grid One side of the bracket 1, the lower end of the grid plate 2 is rotatably connected to the lower end of the grid plate support 1, the gap filling mechanism 6 is connected to the upper end of the grid plate 2, and the support platform 3 is located at the bottom of the grid plate support 1 On the other side, the support platform 3 is horizontally connected to the lower end of the grid support 1, the hydraulic cylinder 5 is installed on the support platform 3 through the movable support 4, and the hydraulic cylinder 5 is connected to the grid 2 through the piston rod. connected to the upper end of the grid plate 2, the piston rod is flexibly connected to the upper end of the grid plate 2, the induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com