Device and method for mounting and dismounting crane boom

A technology of lifting arms and lifting wire ropes, which is applied to cranes and other directions, can solve the problems of high labor costs, low operating efficiency, and inability to successfully place the roof layer with the lifting arm connection, and achieve the effect of reducing labor costs and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

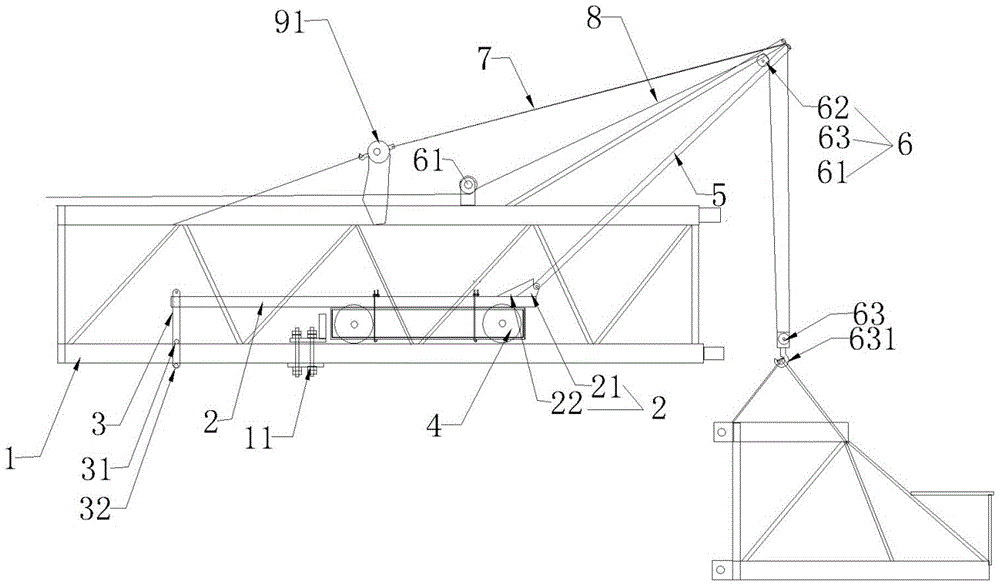

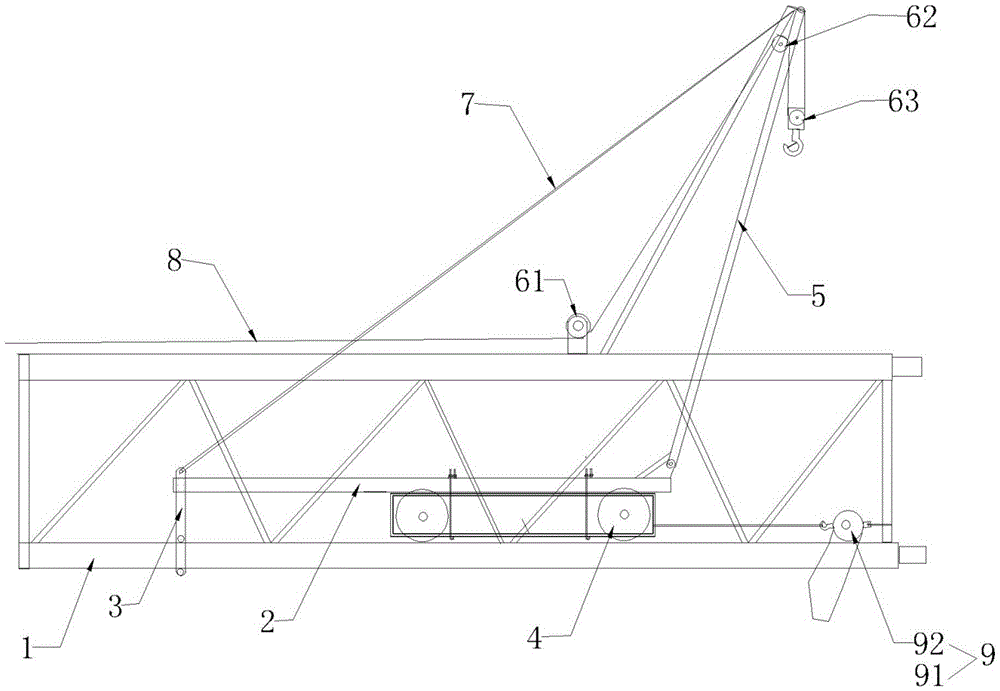

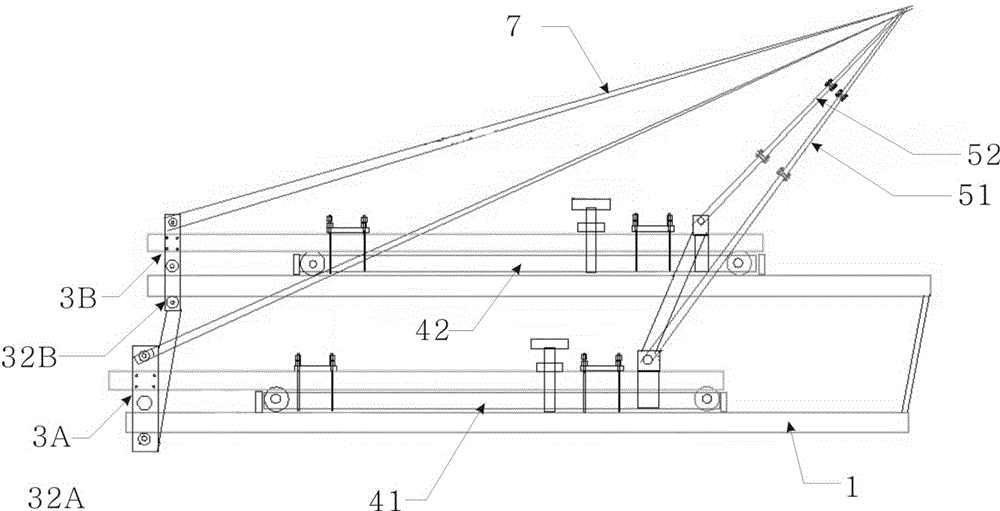

[0036] In order to express the present invention more clearly, the present invention will be further described below with reference to the accompanying drawings.

[0037] See Figure 1-Figure 2 , The present invention provides a device for installing and disassembling a boom, which includes a main rod 1, a transverse steel beam 2, a longitudinal steel beam 3, a luffing trolley 4, a boom crane 5, a movable pulley group 6, a luffing wire rope 7 and The hoisting wire rope 8 and the longitudinal steel beam 3 are vertically fixed on the main steel rod 1 by means of pressing wheels 31 and hook wheels 32. The horizontal steel beam 2 is placed horizontally and parallel to the lower end of the main steel rod 1, and the horizontal steel beam 2 One end of the steel beam is fixedly connected with the longitudinal steel beam 3 by screws, and the other end is welded with a boom crane base 21 for fixing the boom crane 5. The whole boom crane is in the shape of an inverted "V", and its shape can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com